Silicon monoxide-based negative electrode material with high reversible capacity, preparation and application thereof

A silicon oxide-based, silicon oxide technology, applied in nanotechnology, battery electrodes, electrochemical generators, etc. for materials and surface science, can solve problems such as limited refinement effect, prevent agglomeration effect, Good uniformity and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054]The present invention also provides a method for preparing a highly reversible capacity of a silicon oxide negative electrode material comprising the step of: ball milling of the raw material or the raw material and the engaging agent to obtain a silicon oxide compound negative electrode material.

[0055]The raw materials include silicon oxide and tin flour, cobalt powder; or silicon oxide, tin powder, cobalt powder, and carbon material. When the raw material does not contain carbon material, the joining agent is added, the maunder is graphite or ethanol; the amount of the coating agent is from 3% to 6% of the total mass of the raw material. When the raw material contains a carbon material, no engraguing agent or add liquid engagement agent; the liquid engagement agent is ethanol, the amount of the liquid carrier is 3% to 6% of the total mass of the raw material, at which time the material is silicon oxide , Tin powder, cobalt powder and carbon material.

[0056]The present inventi...

Embodiment 1

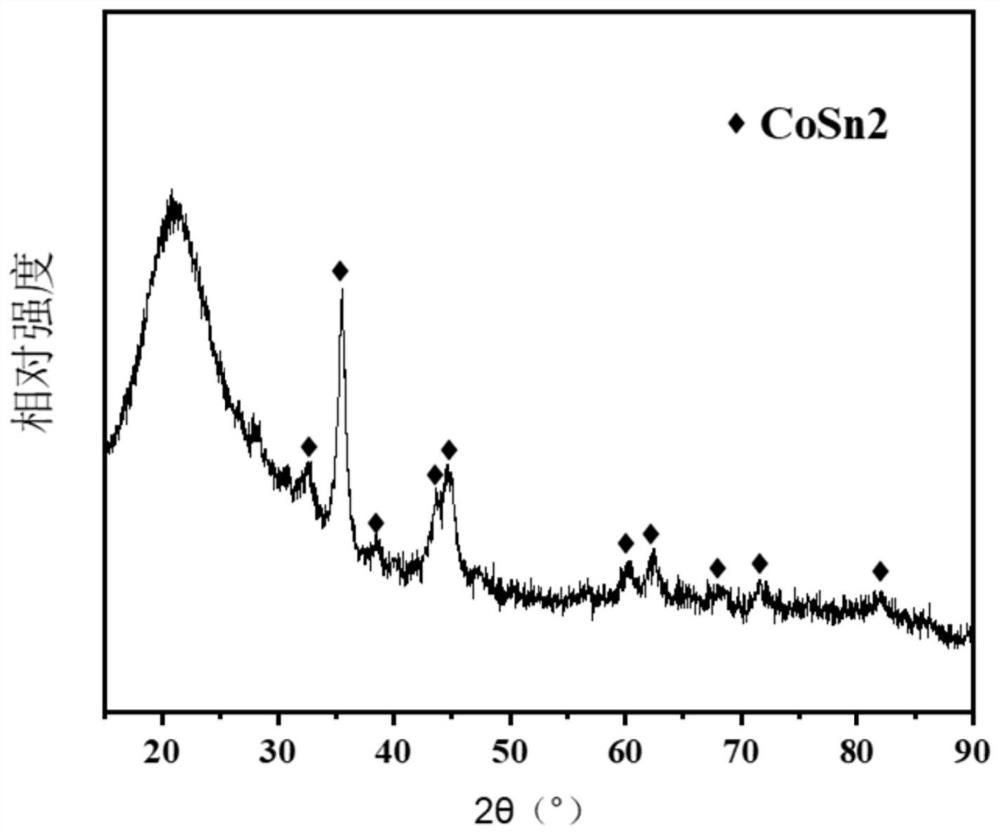

[0070]The method of preparing the SiO-Sn-Co composite (i.e., a silicon oxide negative electrode material having a highly reversible capacity), comprising the steps of:

[0071]Mixed silicon oxide, tin powder and cobalt powder, wherein the mass ratio of silicon oxide, tin powder and cobalt powder is 7: 2: 1, and anhydrous ethanol which is 3% of the total mass of the raw material. Ball mill, wherein the mass ratio of the mill and the raw material powder is 25: 1, the ball milling time is 2 h; obtaining a SiO-Sn-Co composite, i.e., a silicon oxide negative electrode material having a powder scale of less than 10 μm.

[0072]The specific steps of the ramp ball mill are as follows:

[0073](1) Mounting grinding balls and mixing materials in the ball mill (pure silicon oxide, tin powder, cobalt powder and noqueous ethanol);

[0074](2) The canister is surrounded by argon, so that the atmosphere in the can is argon;

[0075](3) Turn on the ball mill power, set the ball mill as "two-way operation, timing ...

Embodiment 2

[0081]The preparation method of the SiO-Sn-CO composite (i.e., a silicon oxide negative electrode material having a highly reversible capacity) is the same as in Example 1, and the ball mill is 4 h (one-way operating time is 30 min, Stop running time is 30 min, the number of runs is 8 times).

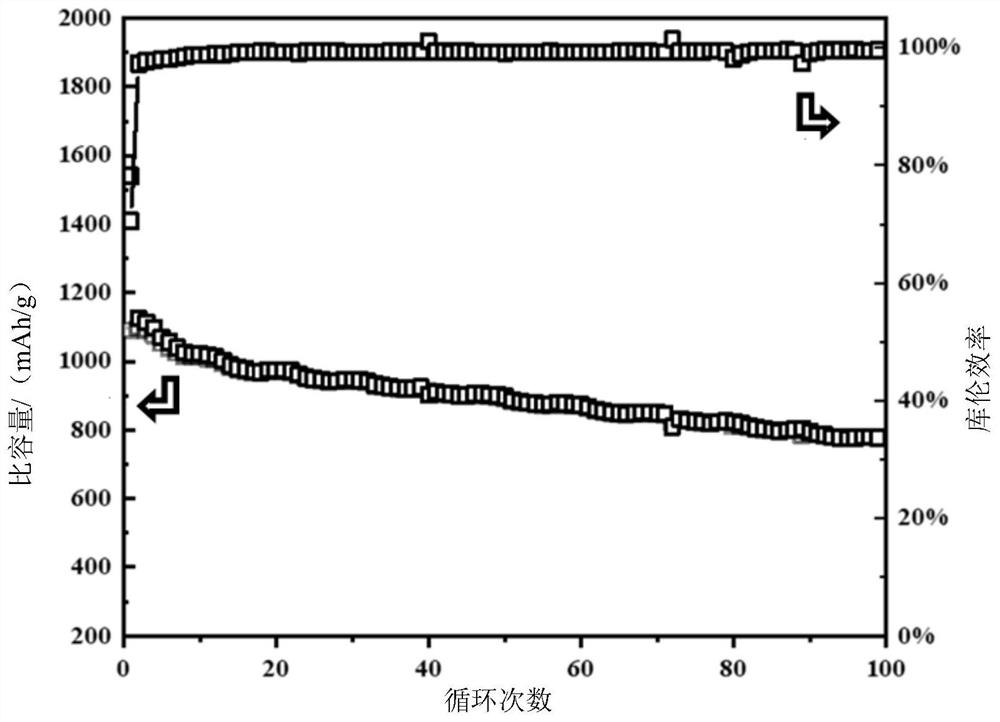

[0082]Figure 4 A backnaming SEM diagram of the SiO-Sn-CO based negative electrode material prepared by the present embodiment, as shown, the ball mill is a secondary particle composed of size particles, wherein the sub-Co alloy compound (bright area) is closely sticked. Attached or embedded in large SiO particles. In this structure, tin cobalt phase can be used as an electron / ion transport passage of the silica particles, which is advantageous for embedding and extraction of lithium ions in the particles.

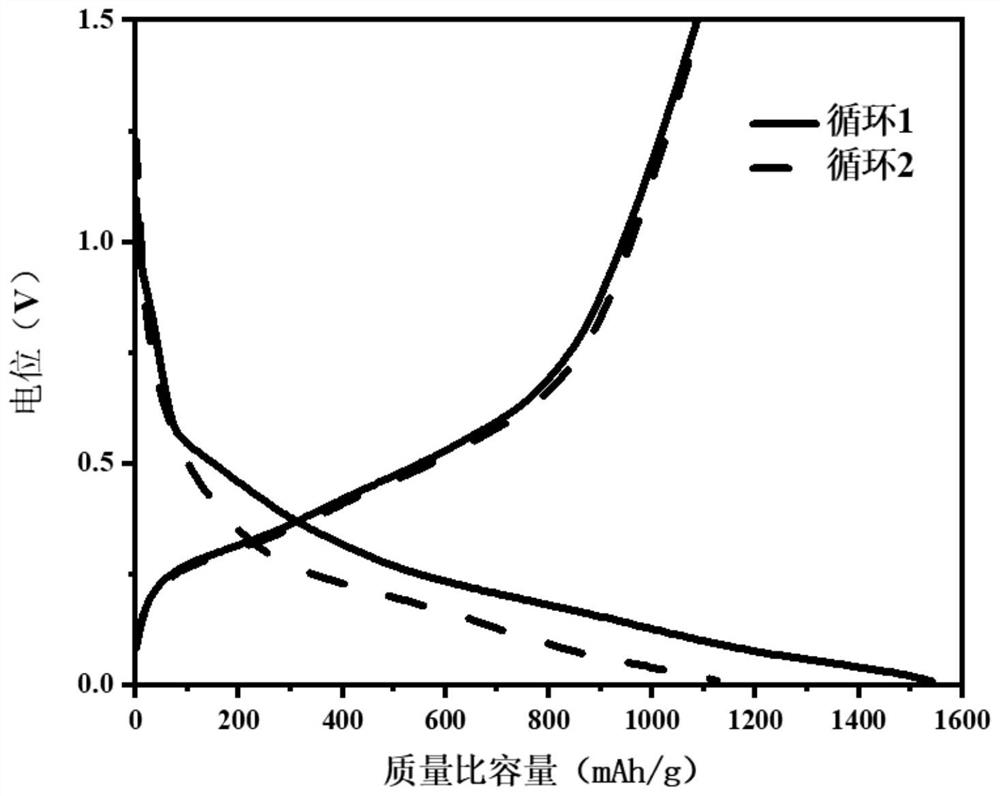

[0083]Figure 5 The voltage-normalized capacity curve of the SiO-Sn-Co composite negative electrode prepared according to the present embodiment, as shown in the figure, a pure SiO negative ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com