Silicon dioxide aerogel material and preparation method and application thereof

A technology of silica and airgel, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve the problem of inability to cross-link monomers and oligomers, and inability to form three-dimensional solids Network structure and other issues to achieve good carbon dioxide adsorption performance, ensure purity, and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

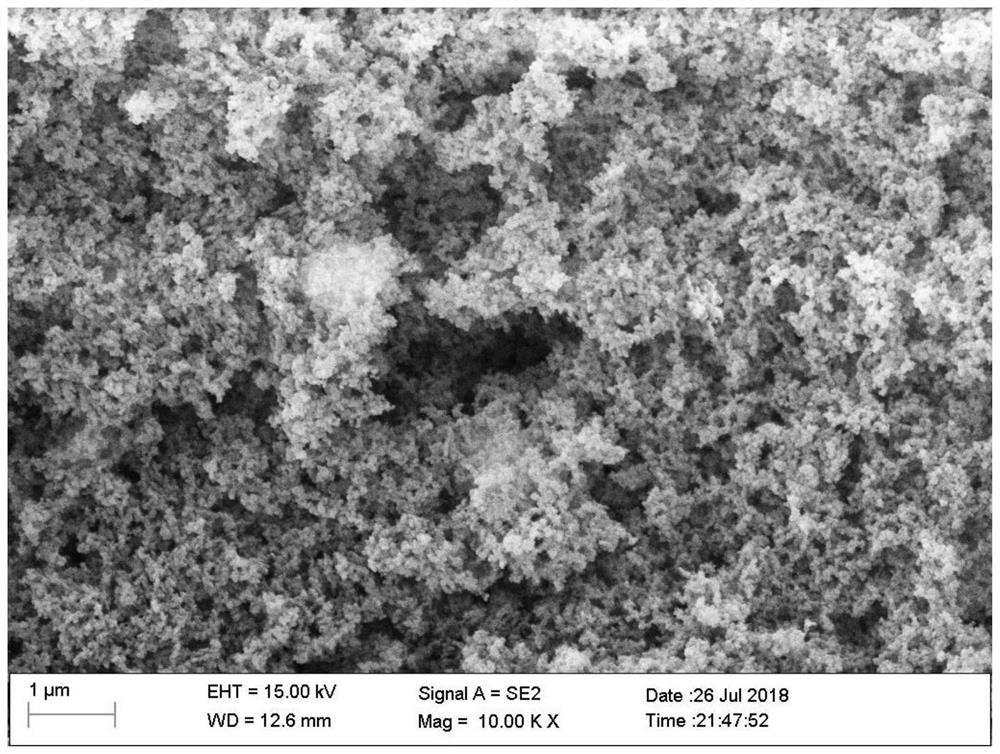

[0022] This embodiment provides a kind of preparation method of silica airgel material, it comprises the following steps:

[0023] S1. Mix 15 mL of dimethyl sulfoxide and 5.05 mL of deionized water, then add 5 mL of methyltrimethoxysilane for mixing, and use a magnetic stirrer to stir at a constant temperature for 60 minutes to obtain a mixed solution.

[0024] S2. Add 1.5 mL of ammonia water with a concentration of 1 mol / L to the above mixed solution, stir rapidly for 0.8 min, and then cast in a mold to perform gelation for 30 min to obtain a wet gel.

[0025] S3. After placing the wet gel at room temperature for 24 hours of static aging, then soak it in ethanol for 24 hours, then wash it with acetone (exchange the ethanol three times with fresh acetone, 24 hours each time) and treat it with carbon dioxide supercritical drying. The silica airgel material can be obtained.

Embodiment 2

[0027] This embodiment provides a kind of preparation method of silica airgel material, it comprises the following steps:

[0028] S1. Mix 30 mL of dimethyl sulfoxide and 5.05 mL of deionized water, then add 5 mL of methyltrimethoxysilane for mixing, and use a magnetic stirrer to stir at a constant temperature for 60 minutes to obtain a mixed solution.

[0029] S2. Add 1.5 mL of ammonia water with a concentration of 1 mol / L to the above mixed solution, stir rapidly for 0.8 min, and then cast in a mold to perform gelation for 30 min to obtain a wet gel.

[0030] S3. After placing the wet gel at room temperature for 24 hours of static aging, then soak it in ethanol for 24 hours, then wash it with acetone (exchange the ethanol three times with fresh acetone, 24 hours each time) and treat it with carbon dioxide supercritical drying. The silica airgel material can be obtained.

Embodiment 3

[0032] This embodiment provides a kind of preparation method of silica airgel material, it comprises the following steps:

[0033] S1. Mix 45 mL of dimethyl sulfoxide and 5.05 mL of deionized water, then add 5 mL of methyltrimethoxysilane for mixing, and use a magnetic stirrer to stir at a constant temperature for 60 minutes to obtain a mixed solution.

[0034] S2. Add 1.5 mL of ammonia water with a concentration of 1 mol / L to the above mixed solution, stir rapidly for 0.8 min, and then cast in a mold to perform gelation for 30 min to obtain a wet gel.

[0035] S3. After placing the wet gel at room temperature for 24 hours of static aging, then soak it in ethanol for 24 hours, then wash it with acetone (exchange the ethanol three times with fresh acetone, 24 hours each time) and treat it with carbon dioxide supercritical drying. The silica airgel material can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com