Preparation method of flame-retardant antistatic ethylene-vinyl acetate copolymer composite material

A vinyl acetate, flame retardant and antistatic technology, which is applied in the field of preparation of flame retardant and antistatic ethylene-vinyl acetate copolymer composite materials, can solve the problems of poor compatibility and no antistatic performance, and achieve good resistance Flame retardant effect, excellent flame retardant performance, good flame retardant performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

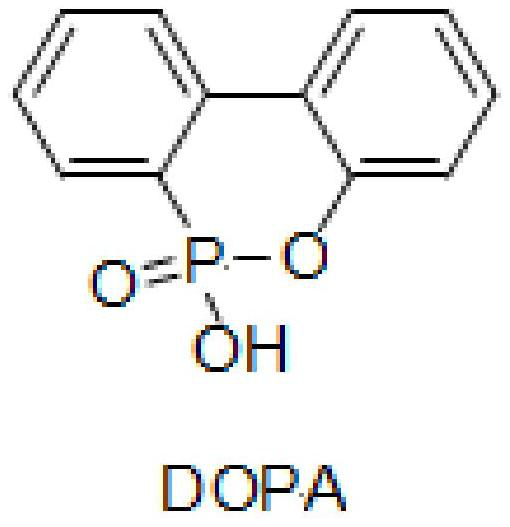

[0032] (1) Preparation of DOPA:

[0033] At room temperature, weigh 10 g (0.046 mol) of 9,10-dihydro-9-oxa-10-phosphophenanthrene-10-oxide (DOPO for short), and put it into a reactor (such as a three-necked flask) , add dropwise 30mL (0.38mol) hydrogen peroxide (the mass percent concentration of the hydrogen peroxide is 30%), and heat up to 60°C, after the dropwise addition of hydrogen peroxide, the temperature rises to 70°C, and react for 8 hours to obtain the reacted material; After the material is cooled to room temperature, it is suction-filtered (normal pressure), and the solid (filter cake) is washed 4 times with solvent acetone, and then put into an oven at a temperature of 100° C. to dry to obtain DOPA;

[0034] The chemical name of DOPA is: 9,10-dihydro-9-oxa-10-phosphorphenanthrene-10-hydroxide;

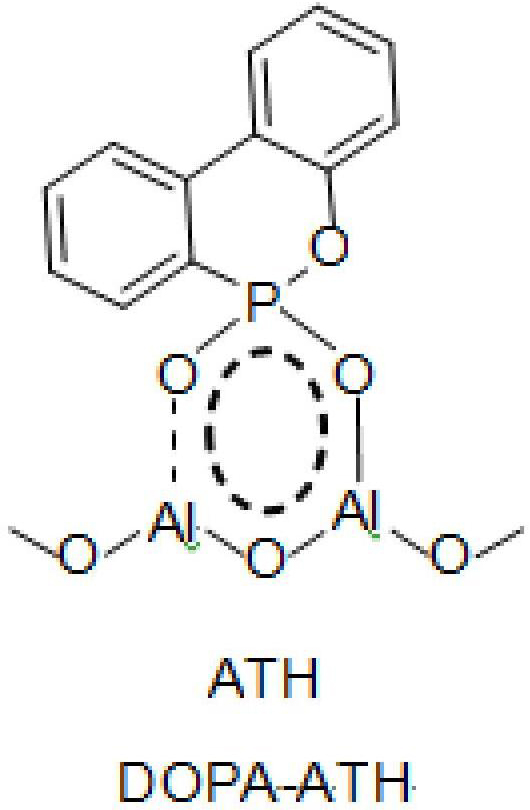

[0035] (2) Preparation of modified aluminum hydroxide flame retardant (DOPA-ATH for short):

[0036] Take by weighing 5g (0.02mol) DOPA and 33g (0.43mol) aluminum hydroxi...

Embodiment 2

[0039] (1) Preparation of DOPA:

[0040] At room temperature, weigh 30g (0.138mol) of 9,10-dihydro-9-oxa-10-phosphophenanthrene-10-oxide (DOPO for short), and put it into a reactor (such as a three-necked flask) , add dropwise 90mL (1.14mol) hydrogen peroxide (the mass percent concentration of the hydrogen peroxide is 30%), and heat up to 70°C, after the dropwise addition of hydrogen peroxide, the temperature rises to 80°C, and react for 6 hours to obtain the reacted material; After the material is cooled to room temperature, it is suction-filtered (normal pressure), and the solid (filter cake) is washed 4 times with the solvent butanone, and then put into an oven at a temperature of 90° C. to dry to obtain DOPA;

[0041] The chemical name of DOPA is: 9,10-dihydro-9-oxa-10-phosphorphenanthrene-10-hydroxide;

[0042] (2) Preparation of modified aluminum hydroxide flame retardant (DOPA-ATH for short):

[0043] Take by weighing 15g (0.06mol) DOPA and 99g (1.29mol) aluminum hydr...

Embodiment 3

[0046] (1) Preparation of DOPA:

[0047] At room temperature, weigh 50g (0.23mol) of 9,10-dihydro-9-oxa-10-phosphophenanthrene-10-oxide (DOPO for short) and put it into a reactor (such as a three-necked flask) , dropwise added 150mL (1.9mol) hydrogen peroxide (the mass percent concentration of the hydrogen peroxide is 30%), and raised the temperature to 70°C, after adding the hydrogen peroxide dropwise, adjusted the temperature to 60°C, and reacted for 9 hours to obtain the reacted material; After the material is cooled to room temperature, it is suction-filtered (at normal pressure), and the solid matter (filter cake) is washed 3 times with the solvent butanone, and then put into an oven at a temperature of 100° C. to dry to obtain DOPA;

[0048] The chemical name of DOPA is: 9,10-dihydro-9-oxa-10-phosphorphenanthrene-10-hydroxide;

[0049] (2) Preparation of modified aluminum hydroxide flame retardant (DOPA-ATH for short):

[0050] Take by weighing 25g (0.1mol) DOPA and 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com