Vibration finishing device and method

A smoothing and vibrating motor technology, which is applied in grinding/polishing equipment, surface-polished machine tools, manufacturing tools, etc., can solve the problem that abrasive particles are difficult to uniformly smooth complex curved surfaces, so as to improve the finishing effect and increase laser power. Vibration and loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

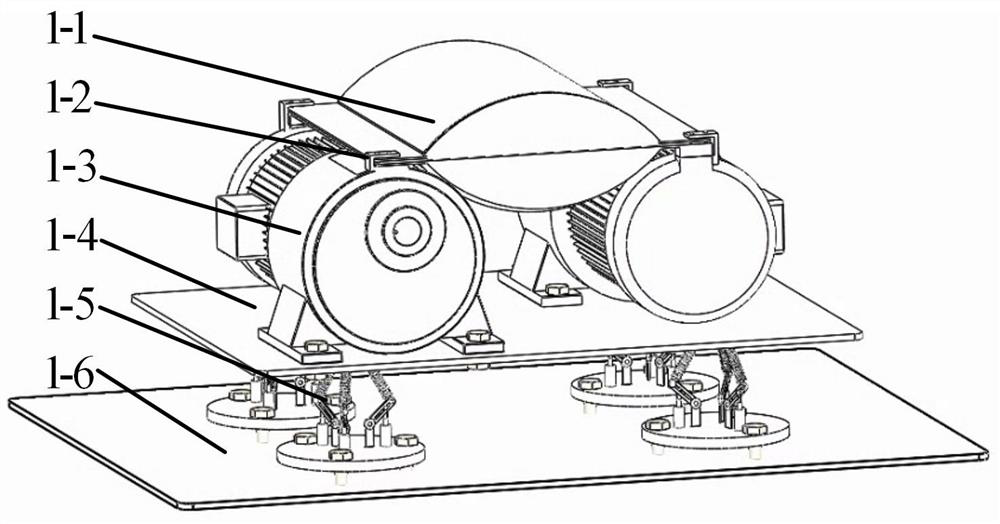

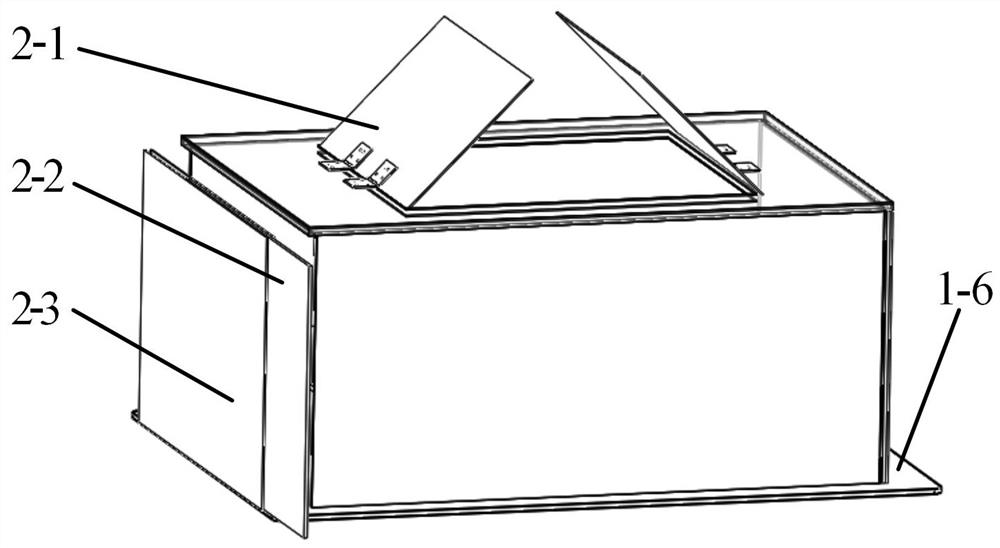

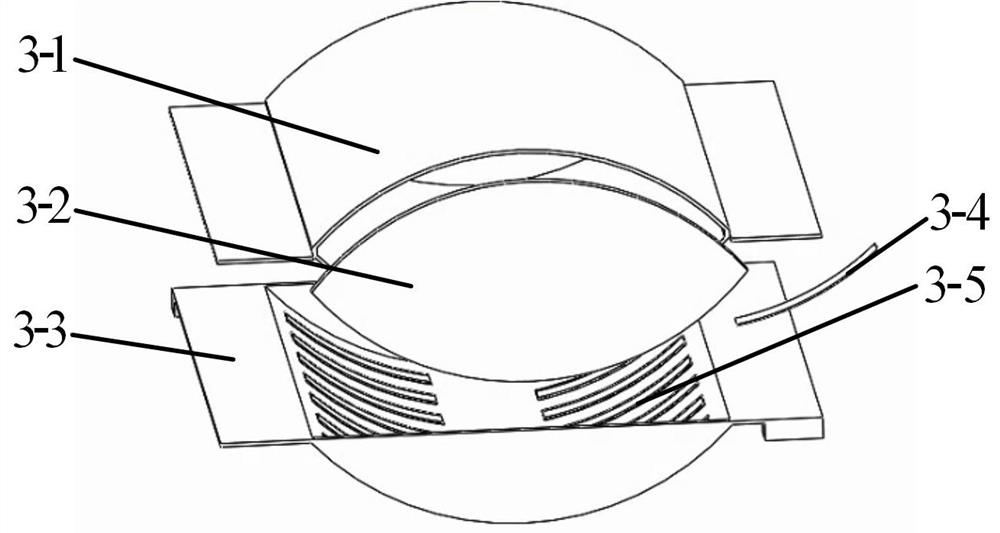

[0017] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 The device described in this embodiment includes a barrel (1-1), a clamp (1-2), a vibration motor (1-3), a vibration connecting plate (1-4), a parallel vibration auxiliary unit (1-5), Base (1-6), window (2-1), sound-absorbing cotton (2-2) and shell (2-3), the barrel (1-1) includes inner baffle (3-1), end a cover (3-2), an outer baffle (3-3) and a magnetic pole (3-4), and the parallel vibration auxiliary unit (1-5) includes a connecting plate (4-1), a spring (4-2), Pneumatic connecting rod (4-3), bolt (4-5), pin shaft (4-6), hydraulic piston rod (4-7) and auxiliary unit base (4-8), the magnetic pole (3-4 ) is installed in the magnetic pole groove (3-5) of the outer baffle (3-3), and the lower end of the inner baffle (3-1) of the installation end cover (3-2) is placed on the outer baffle in a clearance fit manner Inside the plate (3-4), the inner baffle (3-1) and the outer baffle ...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 and image 3 Explain that the outer baffle (3-3) in this embodiment reserves a magnetic pole slot (3-5), and the magnetic pole (3-4) can be installed in the magnetic pole slot (3-5) in a clearance fit manner, and then The non-magnetic abrasives are replaced by magnetic abrasives and placed in the inner baffle (3-1), so as to realize the change of the working purpose from vibration finishing to vibration-assisted magnetic finishing. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 and image 3 Description In this embodiment, the barrel (1-1) with the non-magnetic abrasive or magnetic abrasive and the parts to be processed is directly fixed on the vibration motor (1-3) through the clamp (1-2), and the vibration is directly transmitted to the material. Cylinder (1-1), reduces the loss in the vibration transmission process, increases the vibration amplitude of the material cylinder (1-1) and the excitation force; adjust the frequency of the vibration motor (1-3) through the controller, Further improve the vibration amplitude of the barrel (1-1) and increase the excitation force received, and the others are the same as those of Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com