Biological ceramic scaffold with micro-nano structure on surface and preparation method and application thereof

A technology of bioceramics and bioactive ceramics, applied in the direction of prosthesis, coating, additive processing, etc., to achieve the effect of promoting osteogenic differentiation, repairing bone defects, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 5g of pure feldspar powder was uniformly mixed with 4gF127, and 3D printing technology was used to prepare a feldspar support;

[0040] Calcining the green feldspar stent at 1360°C for 4 hours to obtain a pure feldspar stent;

[0041] Put magnesian feldspar into 0.02mol / L FeSO 4 ·7H 2 Carry out hydrothermal treatment in the aqueous solution of O and L-cysteine, temperature is 180 ℃, time is 12 hours;

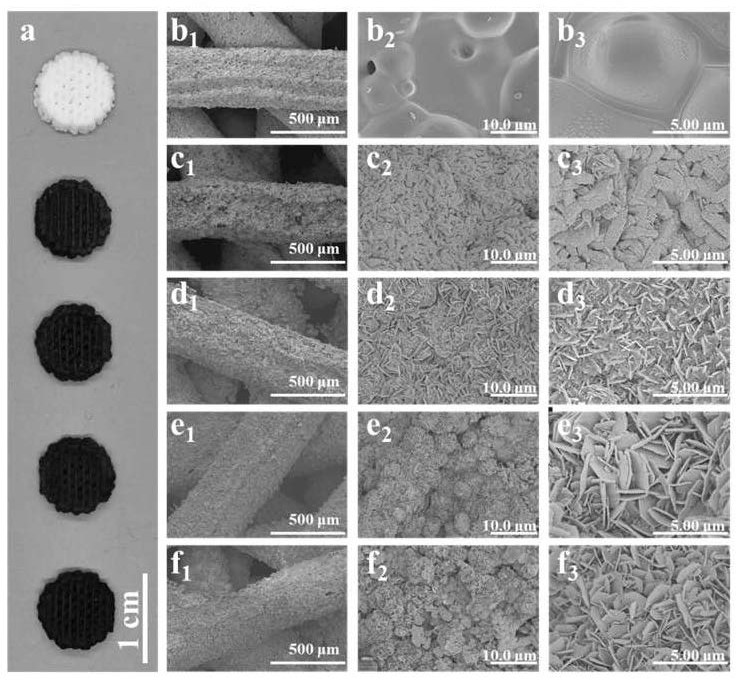

[0042] After hydroheating, the scaffold is rinsed with deionized water and absolute ethanol, and dried in an oven at 60° C. to obtain a bioceramic scaffold decorated with ferric sulfide microflowers. Structural characterization of it, the results are as follows figure 1 As shown in the figure, it can be seen from the figure that the pore diameter of the magnesia feldspar scaffold is 100-400 μm; the iron tetrasulfide grows uniformly on the surface of the magnesia feldspar scaffold; The diameter of the micron flowers is 5-50 μm. Then the osteogenic activity and anti-tu...

Embodiment 2

[0056] 5g of pure feldspar powder was uniformly mixed with 4gF127, and 3D printing technology was used to prepare a feldspar support;

[0057] Calcining the green feldspar stent at 1360°C for 4 hours to obtain a pure feldspar stent;

[0058] Put magnesian feldspar into 0.04mol / L FeSO 4 ·7H 2 Carry out hydrothermal treatment in the aqueous solution of O and L-cysteine, temperature is 160 ℃, time is 24 hours;

[0059] After hydroheating, the scaffold was rinsed with deionized water and absolute ethanol, and dried in an oven at 60° C. to obtain a bioceramic scaffold decorated with ferric sulfide microflowers.

Embodiment 3

[0061] 5g of pure feldspar powder was uniformly mixed with 5g of F127, and 3D printing technology was used to prepare a feldspar support;

[0062] Calcining the green feldspar stent at 1300°C for 3 hours to obtain a pure feldspar stent;

[0063] Put magnesian feldspar into 0.02mol / L FeSO 4 ·7H 2 Carry out hydrothermal treatment in the aqueous solution of O and L-cysteine, temperature is 160 ℃, time is 12 hours;

[0064] After hydroheating, the scaffold was rinsed with deionized water and absolute ethanol, and dried in an oven at 60° C. to obtain a bioceramic scaffold decorated with ferric sulfide microflowers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com