Lanthanum aluminate green ceramic as well as preparation method and application thereof

A technology of lanthanum aluminate and ceramics, which is applied in the field of ceramics, can solve the problems of limitations, failure to meet the requirements of practical application, and great difference in emerald green color, etc., and achieve the effect of high hardness, high toughness, and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a preparation method of lanthanum aluminate green ceramics described in the above technical solution, comprising the following steps:

[0027] Aluminum hydroxide, lanthanum oxide, nickel oxide, chromium oxide and titanium oxide are mixed and wet ground to obtain a slurry; the amount of aluminum hydroxide, lanthanum oxide, nickel oxide, chromium oxide and titanium oxide meets the requirements of the above technical scheme LaAl 11-2X- Y Cr Y Ni X Ti X o 18 stoichiometric ratio;

[0028] Drying and calcining the slurry in sequence to obtain a powder material;

[0029] Pressing the powder material to obtain a ceramic green body;

[0030] The ceramic body is sintered to obtain lanthanum aluminate green ceramics.

[0031] The preparation method provided by the invention is environmentally friendly, pollution-free, less energy consumption, low cost price, short production cycle, simple and controllable, and good repeatability.

[0032] I...

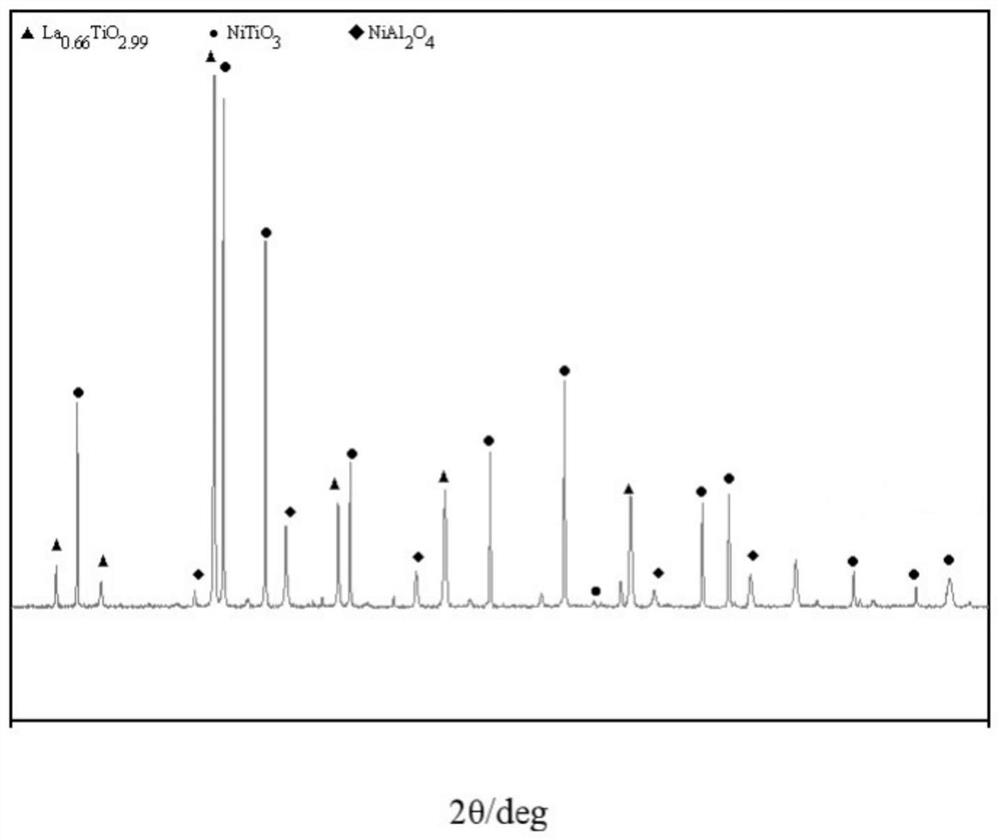

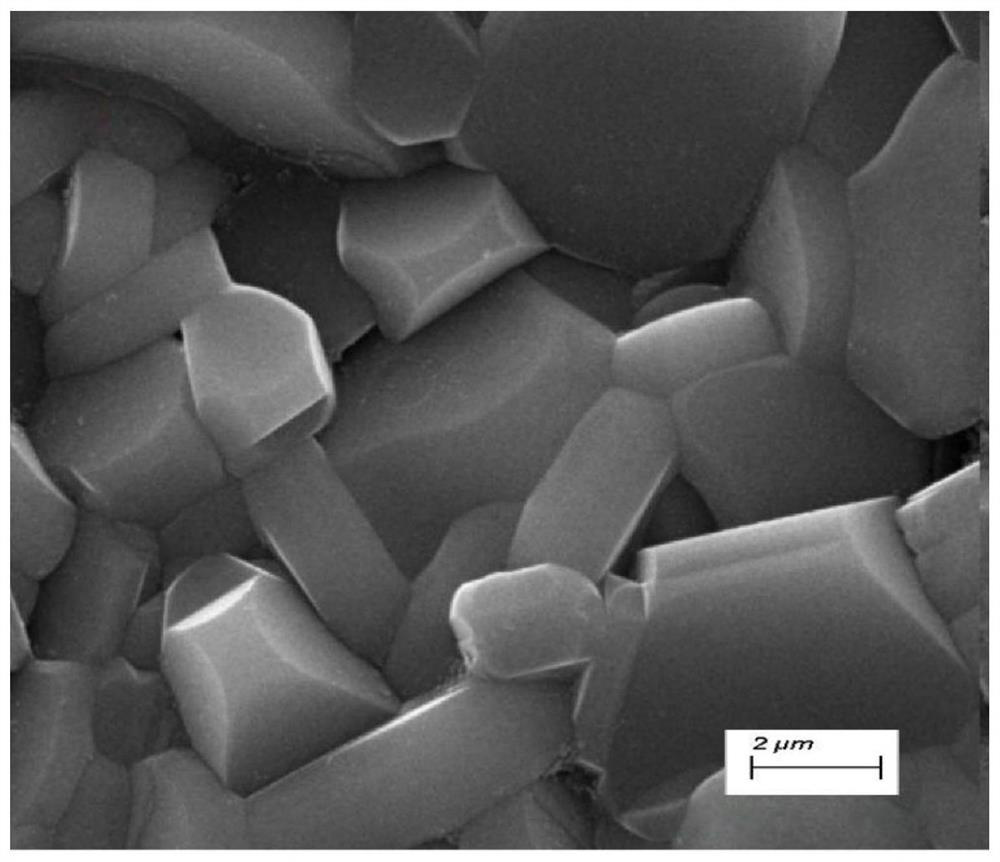

Embodiment 1

[0044] Preparation chemical composition is LaAl 11-2X-Y Cr Y Ni X Ti X o 18 Lanthanum aluminate green ceramics, where X = 1.5, Y = 0.2. Accurately weigh aluminum hydroxide, lanthanum oxide, nickel oxide, chromium oxide and titanium oxide according to the stoichiometric ratio of the above-mentioned X and Y;

[0045] Move the weighed solid raw material into a ball milling tank, pour in absolute ethanol three times the mass of the solid raw material, place the ball milling tank in a star-shaped ball mill, and add oxidized powder with a particle size of 5mm and 10mm according to a ball-to-material ratio of 2:1. Zirconium balls were ball milled for 24 hours at a speed of 4800r / min to obtain a slurry;

[0046] Pour the slurry into a beaker, place it in an oven at a temperature of 80°C to dry, put the dried powder into a box-type electronic furnace, and calcinate it at 600°C for 4 hours to obtain a powder material;

[0047] The powder material is ground and sieved, and pressed ...

Embodiment 2

[0050] Preparation chemical composition is LaAl 11-2X-Y Cr Y Ni X Ti X o 18 Lanthanum aluminate green ceramics, where X=2.0, Y=0.3. Accurately weigh aluminum hydroxide, lanthanum oxide, nickel oxide, chromium oxide and titanium oxide according to the stoichiometric ratio of the above-mentioned X and Y;

[0051] Move the weighed solid raw material into a ball milling tank, pour in absolute ethanol three times the mass of the solid raw material, place the ball milling tank in a star-shaped ball mill, and add oxidizing powder with a particle size of 5 mm and 10 mm according to a ball-to-material ratio of 3:1. Zirconium balls were ball milled for 48 hours at a speed of 4800r / min to obtain a slurry;

[0052] Pour the slurry into a beaker, place it in an oven with a temperature of 80°C to dry, put the dried powder into a box-type electronic furnace, and calcinate it at 700°C for 6 hours to obtain a powder material;

[0053] The powder material is ground and sieved, and pressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com