Expandable alumina-based fiber module and preparation method thereof

A technology based on alumina fiber and alumina, which is applied to ceramic products, clay products, and other household appliances. Shrinkage problems, the effect of avoiding shrinkage seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

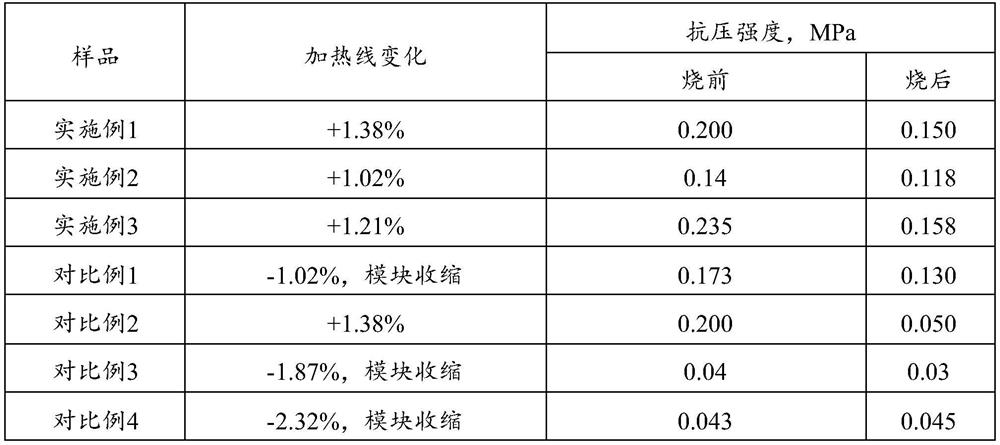

Examples

preparation example Construction

[0043] The invention provides a method for preparing an expandable alumina-based fiber module, comprising the following steps:

[0044] a) mixing alumina fibers, water and a dispersant to obtain a fiber dispersion;

[0045] b) mixing the fiber dispersion with expandable powder, inorganic binder, alum solution and gelatinized starch liquid to obtain fiber slurry;

[0046] c) forming and drying the fiber slurry to obtain an expandable alumina-based fiber module;

[0047] The expandable powder is selected from one or more of organic expansion powder and inorganic expansion powder;

[0048] The organic expansion powder is dipentaerythritol and / or melamine;

[0049] The inorganic expansion powder is selected from one or more of expanded graphite, hydrated alkali metal silicate, vermiculite, perlite, volcanic glass and mica;

[0050] The inorganic binder is low-sodium silica sol.

[0051] In the present invention, the alumina fiber is firstly dispersed to form a fiber dispersion...

Embodiment 1

[0084] S1. Crush the alumina fibers and remove slag; obtain pretreated fibers with a fiber index of 71% and a fiber length of 250 μm.

[0085] S2. Add the pretreated fiber into clear water for dispersion, then add the dispersant polyamide epichlorohydrin resin and mix evenly to obtain a fiber dispersion. Wherein, the mass ratio of alumina fiber to water is 10%, and the mass ratio of dispersant to alumina fiber is 0.15%.

[0086] S3. Add expandable powder to the fiber dispersion and mix well.

[0087] The amount of the expandable powder accounts for 30% of the total mass of the alumina fiber and the expandable powder. Wherein, the organic expansion powder and the inorganic expansion powder are mixed by 50%:50%; the organic expansion powder is dipentaerythritol and melamine, and the mass ratio of the two is 2:1; the inorganic expansion powder is expansion vermiculite.

[0088] S4. Add low-sodium silica sol and alum solution to the system, and mix well.

[0089] Among them, th...

Embodiment 2

[0095] S1. Crush the alumina fibers and remove slag; obtain pretreated fibers with a fiber index of 71% and a fiber length of 250 μm.

[0096] S2. Add the pretreated fiber into clear water for dispersion, then add the dispersant polyamide epichlorohydrin resin and mix evenly to obtain a fiber dispersion. Wherein, the mass ratio of alumina fiber to water is 5%, and the mass ratio of dispersant to alumina fiber is 0.1%.

[0097] S3. Add expandable powder to the fiber dispersion and mix well.

[0098] The amount of the expandable powder accounts for 10% of the total mass of the alumina fiber and the expandable powder. Wherein, the organic expansion powder and the inorganic expansion powder are mixed according to 20%:80%; the organic expansion powder is dipentaerythritol and melamine, and the mass ratio of the two is 1:1; the inorganic expansion powder is expanded graphite.

[0099] S4. Add low-sodium silica sol and alum solution to the system, and mix well.

[0100] Among them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com