Barium sulfate master batch for plastic pipe and preparation method

A technology of plastic pipes and barium sulfate, applied in the field of plastic processing, can solve the problems of poor ring pressure resistance and brittle pipes, and achieve the effects of preventing brittleness, increasing bending strength and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

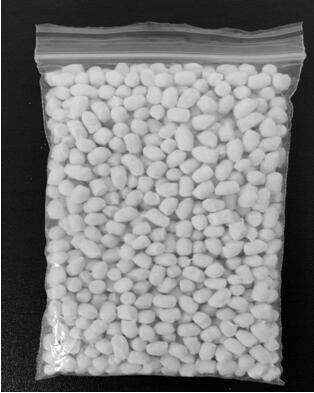

Image

Examples

Embodiment 1

[0027]Grind the precipitated barium sulfate with a D80 particle size of 2 μm and sulfur at a mass ratio of 100:0.2 at 115°C with a ball mill without grinding media, the grinding speed is 80rpm, and the grinding time is 15min, so that the sulfur is evenly distributed on the surface of the barium sulfate, and the pretreatment is obtained. Barium sulfate. Mix SBS, paraffin, DCP, and pretreated barium sulfate at a mass ratio of 5:2:0.01:60, feed them into a screw extruder, and extrude at 120°C. SBS melts into a low-viscosity material under the action of hot melt and paraffin. The pretreatment barium sulfate surface is fully contacted and vulcanized, and the obtained extruded pellets are ground and refined by a vortex airflow refiner to obtain sulfurized SBS-coated barium sulfate fine powder. The vortex airflow refiner host speed is 1000rpm, and the classification Speed 800rpm. The vulcanized SBS-coated barium sulfate fine powder is used as filler, mixed with PP k8303 polypropyl...

Embodiment 2

[0029] Grind the precipitated barium sulfate with a D80 particle size of 2 μm and sulfur at a mass ratio of 100:0.2 at 115°C with a ball mill without grinding media, the grinding speed is 80rpm, and the grinding time is 17min, so that the sulfur is evenly distributed on the surface of the barium sulfate, and the pretreatment is obtained. Barium sulfate. Mix SBS, paraffin, DCP, and pretreated barium sulfate at a mass ratio of 5:2.5:0.01:60, feed them into a screw extruder, and extrude at 120°C. SBS is melted into a low-viscosity material under the action of hot melt and paraffin. The pretreatment barium sulfate surface is fully contacted and vulcanized, and the obtained extruded pellets are ground and refined by a vortex airflow refiner to obtain sulfurized SBS-coated barium sulfate fine powder. The vortex airflow refiner host speed is 1000rpm, and the classification Speed 900rpm. The vulcanized SBS-coated barium sulfate fine powder is used as a filler, mixed with PP k8303 p...

Embodiment 3

[0031] Grind the precipitated barium sulfate with a D80 particle size of 3 μm and sulfur at a mass ratio of 100:0.3 at 115°C with a ball mill without grinding media, the grinding speed is 80rpm, and the grinding time is 18min, so that the sulfur is evenly distributed on the surface of the barium sulfate, and the pretreatment is obtained. Barium sulfate. Mix SBS, paraffin, DCP, and pretreated barium sulfate at a mass ratio of 6:2.5:0.02:70, feed them into a screw extruder, and extrude at 125°C. SBS is melted into a low-viscosity material under the action of hot melt and paraffin. The pretreatment barium sulfate surface is fully contacted and vulcanized, and the extruded pellets obtained are ground and refined by a vortex airflow refiner to obtain sulfurized SBS-coated barium sulfate fine powder. The main engine speed of the vortex airflow refiner is 1100rpm and classified Speed 900rpm. The vulcanized SBS-coated barium sulfate fine powder is used as filler, mixed with PP k830...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com