Structure and method for controlling SCR ammonia spraying amount based on rapid measurement and feedback of NOx concentration at outlet of induced draft fan

A technology of feedback control and induced draft fan, applied in various fluid ratio control, etc., can solve problems such as heavy maintenance workload, poor quality of SCR ammonia injection control, and poor accuracy of single-point measurement values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

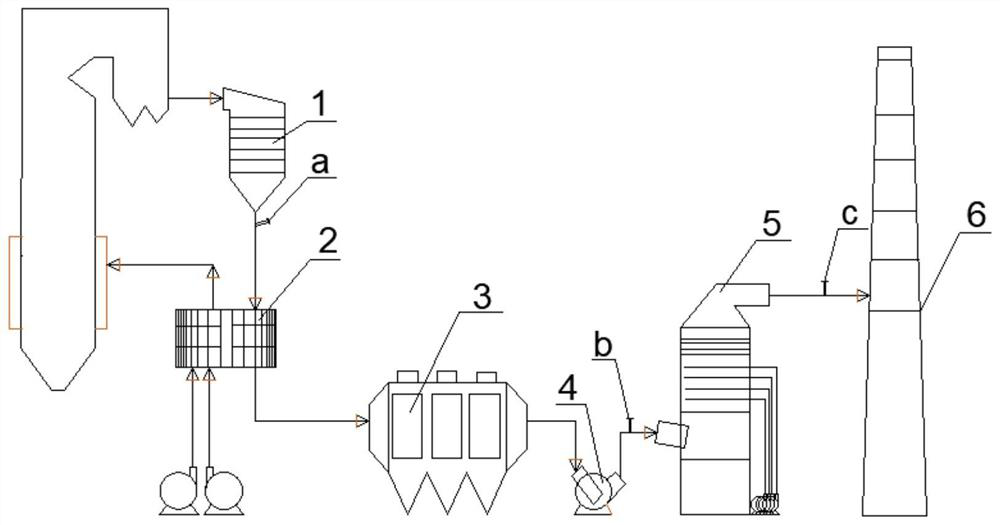

[0022] Such as figure 1 As shown, the structure based on rapid measurement and feedback of NOx concentration at the outlet of the induced draft fan to control the amount of SCR ammonia injection includes the sequentially connected SCR denitration device, air preheater, dust collector, induced draft fan and chimney. Both the outlet of the SCR denitrification device and the inlet of the chimney are installed With CEMS, NOx concentration rapid measuring instrument is installed at the outlet of induced draft fan, NOx concentration rapid measuring instrument T 90 The response time is less than 30s, and the signal output adopts redundant design, at least two NOx measurement signals can be output at the same time, as disclosed in the patent "A Flue Gas Pretreatment System for NOx Rapid Measurement Instrument" (Patent No. 2020201861282) NOx concentration rapid measuring instrument; the NOx concentration at the outlet of the induced draft fan is used as the feedback signal for the cont...

Embodiment 2

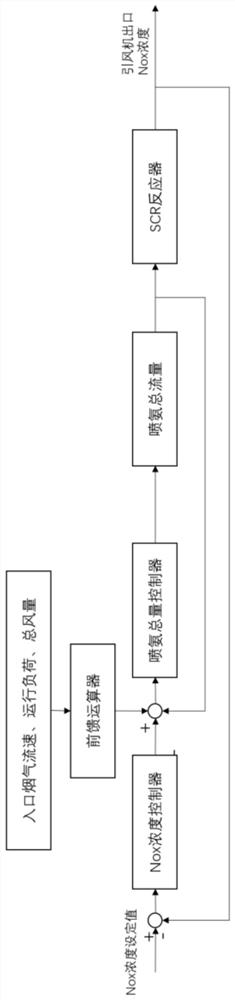

[0025] Basically the same as Embodiment 1, the difference is: after obtaining the feedback signal (NOx concentration at the outlet of the induced draft fan), the control loop is as follows figure 2 As shown, the differential calculator in the DCS control system obtains the total amount of ammonia injection required, and the comprehensive calculation results in the DCS control system combined with parameters such as operating load and total air volume are used as the feedforward amount in the total amount of ammonia injection control system , after the NOx concentration set value is compared with the NOx deviation at the outlet of the induced draft fan, it is calculated and calculated with the introduced feed-forward value as the set value of the ammonia injection total controller, and the SCR area is controlled by the inlet flue ammonia injection master valve. The total amount of ammonia injection is precisely controlled. Through the above control strategies, on the premise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com