Preparation method of sulfur and nitrogen double-doped lithium air battery positive electrode catalyst

A lithium-air battery, double-doped technology, applied in battery electrodes, carbon preparation/purification, fuel cell half-cells and secondary battery half-cells, etc., can solve problems such as poor catalytic activity and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

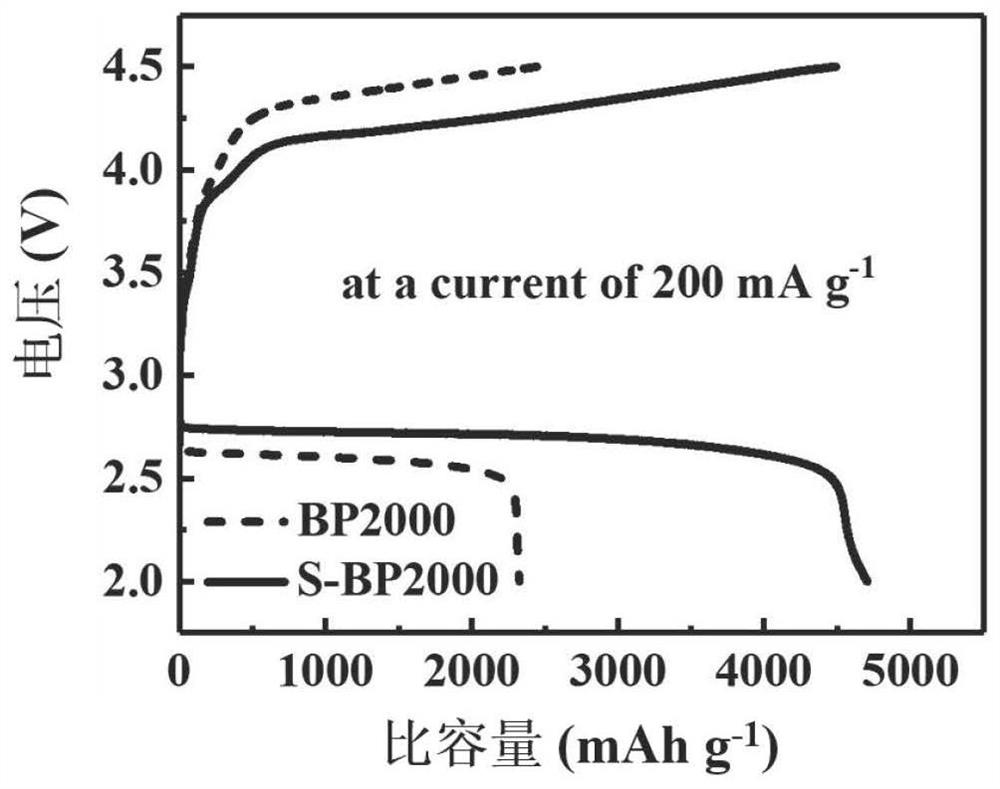

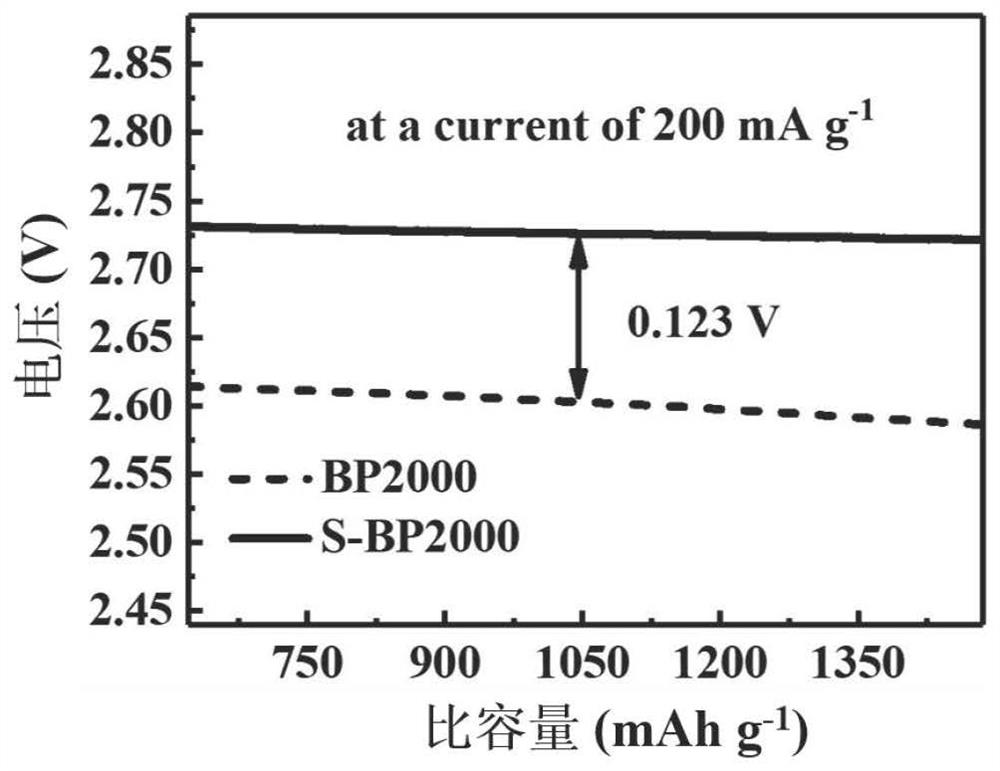

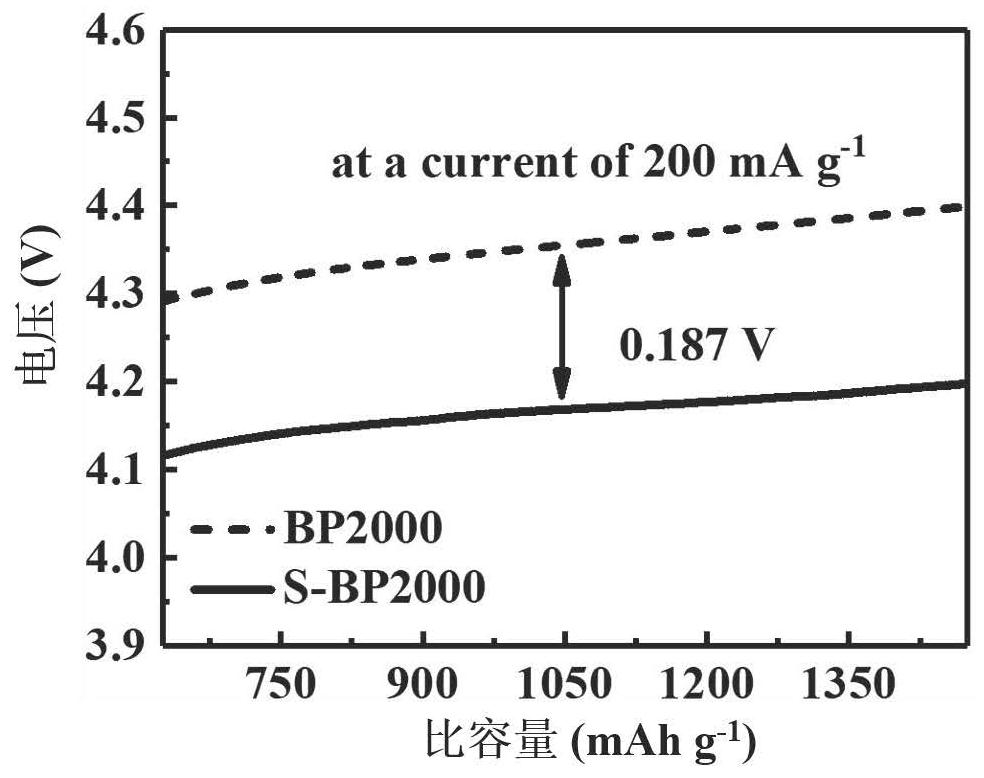

[0022] Specific implementation mode 1: This implementation mode records a method for preparing a sulfur-nitrogen double-doped lithium-air battery cathode catalyst. The method is specifically:

[0023] Step 1: After mixing the raw materials containing sulfur and nitrogen with the carbon matrix in a solvent, transfer them to a closed reaction vessel, and perform solvothermal reaction at 150-260°C to form a precursor dispersion;

[0024] Step 2: The precursor dispersion liquid is subjected to centrifugal washing, vacuum-dried, and then subjected to high-temperature pyrolysis under a protective atmosphere to obtain lithium-air battery cathode catalyst powder.

[0025] The air positive electrode of the present invention uses carbon material as a matrix material, and raw materials containing sulfur and nitrogen elements interact with the carbon matrix through chemical reactions to form a lithium-air battery positive electrode catalyst doped with sulfur and nitrogen elements.

specific Embodiment approach 2

[0026] Specific embodiment two: the preparation method of a sulfur-nitrogen double-doped lithium-air battery positive electrode catalyst described in specific embodiment one, the raw material containing two elements of sulfur and nitrogen contains two elements of sulfur and nitrogen at the same time of organic matter.

specific Embodiment approach 3

[0027] Specific embodiment three: the preparation method of a kind of sulfur, nitrogen double-doped lithium-air battery anode catalyst described in specific embodiment two, the organic matter that contains sulfur, nitrogen two kinds of elements at the same time is thioformamide, thiosulfate One of acetamide, thiophosphoramide, or thiosemicarbazide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com