Preparation method and application of N-doped FeMnO3 electrode material

An electrode material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

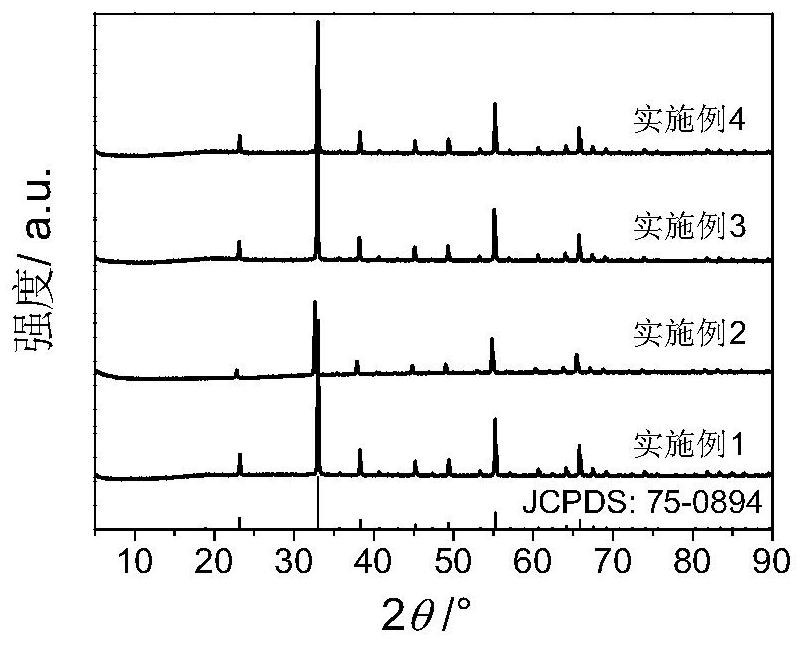

Examples

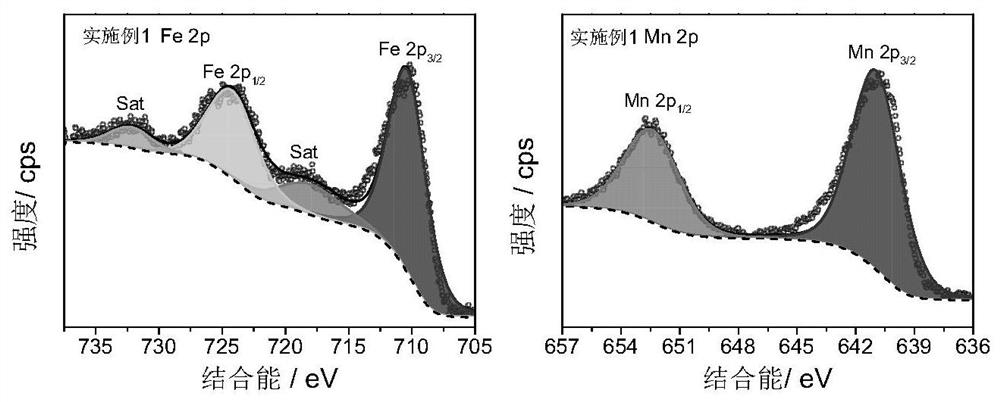

Embodiment 1

[0019] (1) Take ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) and manganese sulfate monohydrate (MnSO 4 ·H 2 O) and mix, add an appropriate amount of distilled water to dissolve, so that the concentrations of iron ions and manganese ions in the iron-manganese mixed solution are both 0.10 mol / L.

[0020] (2) Measure 100 mL of the iron-manganese mixed solution obtained in step (1) and place it in a 500 mL reactor, add 200 mL of 2.67 mol / L ammonia solution dropwise to it while stirring at a constant temperature of 25 °C, and stir The speed is 350 rpm; after the ammonia water is added dropwise, the stirring reaction is continued for 3 hours, and the stirring is stopped; then the reactor is placed at room temperature and aged for 12 hours; finally, the precipitate is filtered, washed, and freeze-dried to obtain Precursor powder.

[0021] (3) Measure 15 mL of ethanol aqueous solution (the volume ratio of absolute ethanol to distilled water is 1:2), and add 0.1 g of the precursor...

Embodiment 2

[0024] (1) Take ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) and manganese sulfate monohydrate (MnSO 4 ·H 2 O) and mix, add an appropriate amount of distilled water to dissolve, so that the concentrations of iron ions and manganese ions in the iron-manganese mixed solution are both 0.10 mol / L.

[0025] (2) Measure 100 mL of the iron-manganese mixed solution obtained in step (1) and place it in a 500 mL reactor, add 200 mL of 2.67 mol / L ammonia solution dropwise to it while stirring at a constant temperature of 25 °C, and stir The speed is 350 rpm; after the ammonia water is added dropwise, the stirring reaction is continued for 3 hours, and the stirring is stopped; then the reactor is placed at room temperature and aged for 12 hours; finally, the precipitate is filtered, washed, and freeze-dried to obtain Precursor powder.

[0026] (3) Weigh 0.5 g of analytically pure NH 4 HCO 3 In 15 mL of ethanol aqueous solution (the volume ratio of absolute ethanol to distilled wate...

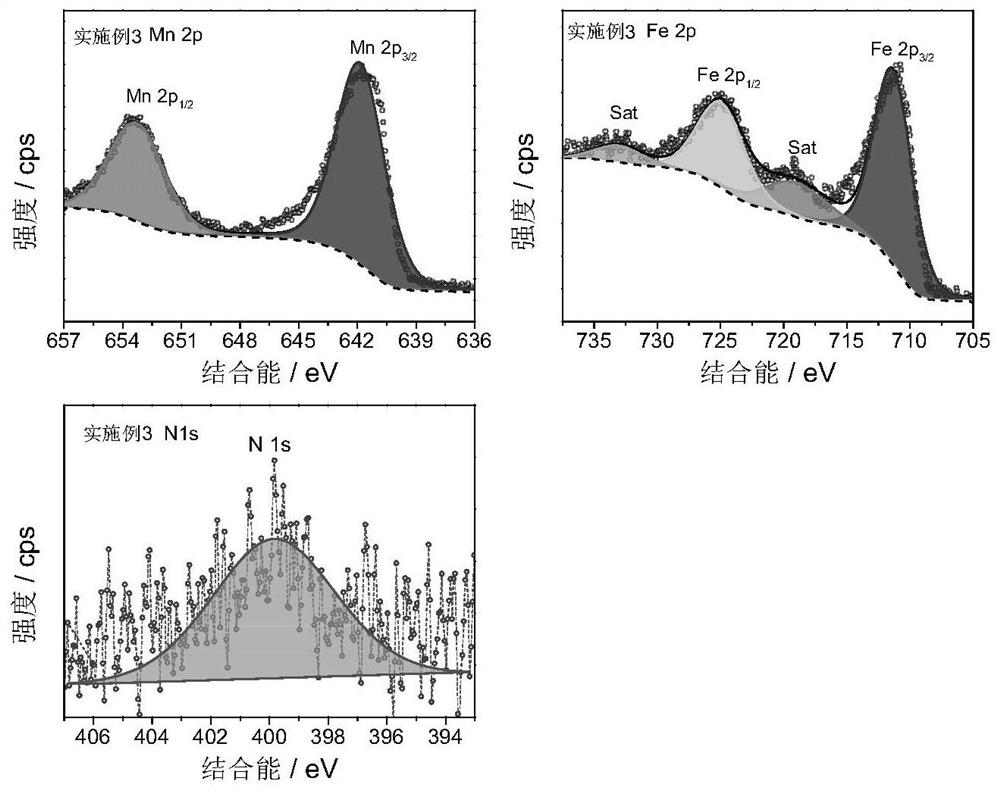

Embodiment 3

[0029] (1) Take ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) and manganese sulfate monohydrate (MnSO 4 ·H 2 O) and mix, add an appropriate amount of distilled water to dissolve, so that the concentrations of iron ions and manganese ions in the iron-manganese mixed solution are both 0.10 mol / L.

[0030](2) Measure 100 mL of the iron-manganese mixed solution obtained in step (1) and place it in a 500 mL reactor, add 200 mL of 2.67 mol / L ammonia solution dropwise to it while stirring at a constant temperature of 25 °C, and stir The speed is 350 rpm; after the ammonia water is added dropwise, the stirring reaction is continued for 3 hours, and the stirring is stopped; then the reactor is placed at room temperature and aged for 12 hours; finally, the precipitate is filtered, washed, and freeze-dried to obtain Precursor powder.

[0031] (3) Weigh 1.0 g of analytically pure NH 4 HCO 3 In 15 mL of ethanol aqueous solution (the volume ratio of absolute ethanol to distilled water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com