Treatment method and application of high-COD high-phosphorus heavy metal-containing sewage

A treatment method and heavy metal technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem that heavy metals, COD and phosphorus cannot be removed simultaneously in sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0068] The zeolite-modified cationic polyacrylamide used in the examples and comparative examples was prepared according to the following method.

[0069] (1) Zeolite pretreatment: Put 1 g of zeolite with particles of -60 mesh to +100 mesh into a beaker, add 100 mL of 1% HCl, stir for 3 hours, filter, and wash with deionized water until the filtrate is neutral, and the solid is stored at 60 °C Dry for 6 hours;

[0070] (2) Dissolution of cationic polyacrylamide: add 1 g of cationic polyacrylamide to 1 L of deionized water, stir at 800 rpm for 3 h;

[0071] (3) Zeolite-modified cationic polyacrylamide: Add 0.2 g of zeolite treated in (1) to (2), stir and react at 60°C for 4 hours, then continue to react in an oven at 60°C for 6 hours to obtain zeolite-modified polyacrylamide. Acrylamide.

[0072] Among them, the types of zeolite and the cationic degree of cationic polyacrylamide are shown in Table 1.

[0073] Table 1

[0074] Zeolite modified cationic polyacrylamid...

Embodiment 1

[0076] (1) Adjust the pH value of the sewage to 7.6 in the sewage regulating tank;

[0077] (2) Sewage flows into the reaction tank, add ferric chloride 2500mg / L, stir and react for 10 minutes, add mordenite modified cationic polyacrylamide A1 8mg / L, continue stirring and reacting for 6 minutes;

[0078] (3) The mixed solution flows into the sedimentation tank for solid-liquid separation, the residence time is 10min, 60% of the flocs are returned to the reaction tank, the remaining flocs are concentrated, press-filtered, landfilled, the supernatant of the concentrated flocs and the press-filtered water return to the reaction pool;

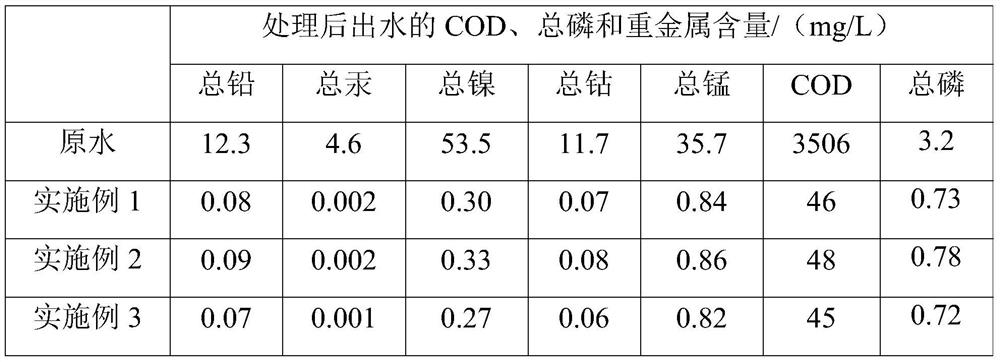

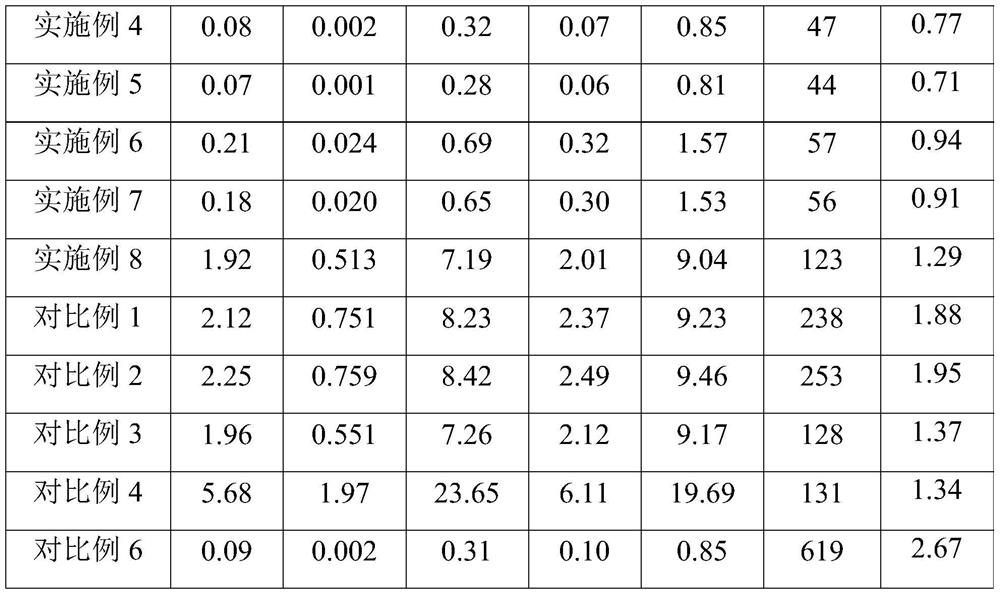

[0079] (4) The effluent from the sedimentation tank enters the organic titanium adsorption reaction tank, the dosage of organic titanium adsorbent is 5‰, and the reaction time is 30 minutes. The heavy metal contents and COD values in the discharged water are shown in Table 2.

Embodiment 2

[0081] (1) Adjust the pH value of the sewage to 5.6 in the sewage regulating tank;

[0082] (2) Sewage flows into the reaction tank, add iron sulfate 1500mg / L, stir and react for 2 minutes, add stilbite-modified cationic polyacrylamide A2 4mg / L, continue to stir and react for 3 minutes;

[0083] (3) The mixed solution flows into the sedimentation tank for solid-liquid separation, the residence time is 5min, 25% of the flocs are returned to the reaction tank, the remaining flocs are concentrated, press-filtered, landfilled, the supernatant of the concentrated flocs and the press-filtered water return to the reaction pool;

[0084] (4) The effluent from the sedimentation tank enters the organic titanium adsorption reaction tank, the dosage of organic titanium adsorbent is 2‰, and the reaction time is 10 minutes. The heavy metal contents and COD values in the discharged water are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com