Preparation method of black zirconia ceramic material

A technology of black zirconia and ceramic materials, applied in the field of zirconia ceramics, which can solve the problems of difficulty in making uniformly colored black zirconia ceramics, environmental and human health hazards, and pinholes on the surface of ceramic products, so as to achieve good anti-aging properties, improve gloss, and prevent low-temperature degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

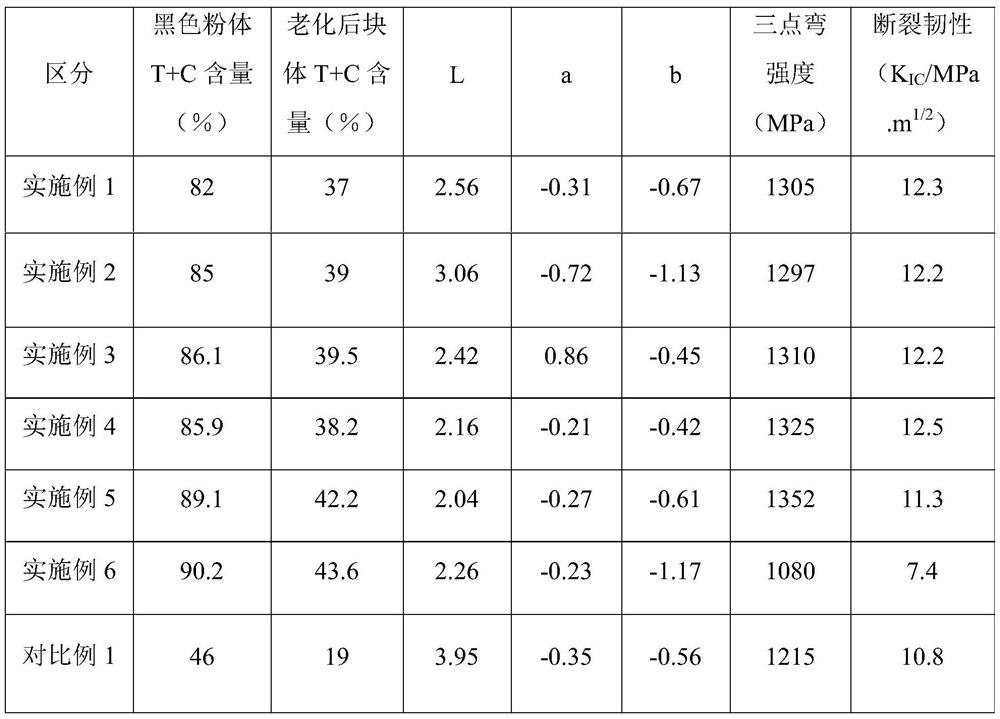

Examples

Embodiment 1

[0039] (1) Mix zirconium oxychloride and yttrium trichloride solutions in a high-pressure reactor, the heating temperature is 140° C., the holding time is 4 hours, add citric acid solution to prepare a gel solution, add sodium hydroxide solution to neutralize, The pH value is controlled at 8. Wherein, the zirconium oxychloride solution is measured by the mass of solute zirconia, and the yttrium trichloride solution is measured by the mass of solute yttrium oxide. In the chemical composition, the mass ratio of (zirconia + hafnium oxide): yttrium oxide is 96.22:3.78. The amount of the organic acid added is based on the mass of the solute, and is 10% of the total mass of the two oxides of zirconia and yttrium oxide.

[0040] (2) After dechlorinating and desodiumizing the neutralized product, carry out microwave crystallization treatment, the treatment temperature is 500°C, and the holding time is 1 hour, to obtain a highly dispersed and highly tetragonal yttrium-zirconium precur...

Embodiment 2

[0055] (1) Mix zirconium oxychloride and yttrium trichloride solutions in a high-pressure reactor, the heating temperature is 140° C., the holding time is 4 hours, add citric acid solution to prepare a gel solution, add sodium hydroxide solution to neutralize, The pH is controlled at 11. Wherein, the zirconium oxychloride solution is measured by the mass of solute zirconia, and the yttrium trichloride solution is measured by the mass of solute yttrium oxide. In the chemical composition, the mass ratio of (zirconia + hafnium oxide): yttrium oxide is 96.22:3.78. The amount of the organic acid added is based on the mass of the solute, and is 10% of the total mass of the two oxides of zirconia and yttrium oxide.

[0056] (2) After dechlorinating and desodiumizing the neutralized product, carry out microwave crystallization treatment, the treatment temperature is 500°C, and the holding time is 1 hour, to obtain a highly dispersed and highly tetragonal yttrium-zirconium precursor: ...

Embodiment 3

[0067] (1) Mix zirconium oxychloride and yttrium trichloride solutions in a high-pressure reactor, the heating temperature is 140° C., the holding time is 4 hours, add citric acid solution to prepare a gel solution, add sodium hydroxide solution to neutralize, The pH value is controlled at 8-11. Wherein, the zirconium oxychloride solution is measured by the mass of solute zirconia, and the yttrium trichloride solution is measured by the mass of solute yttrium oxide. In the chemical composition, the mass ratio of (zirconia + hafnium oxide): yttrium oxide is 96.22:3.78. The amount of the organic acid added is based on the mass of the solute, and is 10% of the total mass of the two oxides of zirconia and yttrium oxide.

[0068] (2) After dechlorinating and desodiumizing the neutralized product, carry out microwave crystallization treatment, the treatment temperature is 600°C, and the holding time is 1 hour to obtain a highly dispersed and highly tetragonal yttrium-zirconium prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com