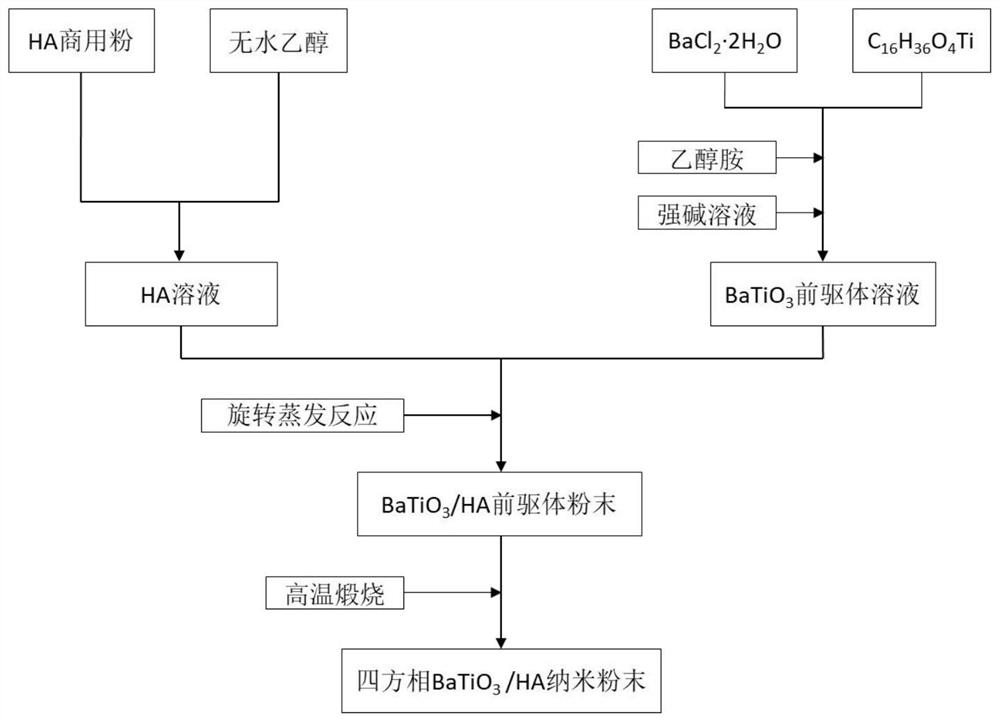

Method for preparing tetragonal BaTiO3/HA composite nanoparticles by liquid-phase rotary evaporation method

A composite nanoparticle and tetragonal technology, applied in medical science, prosthesis, etc., can solve the problems of high brittleness and poor strength, and achieve the effect of low cost, high performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

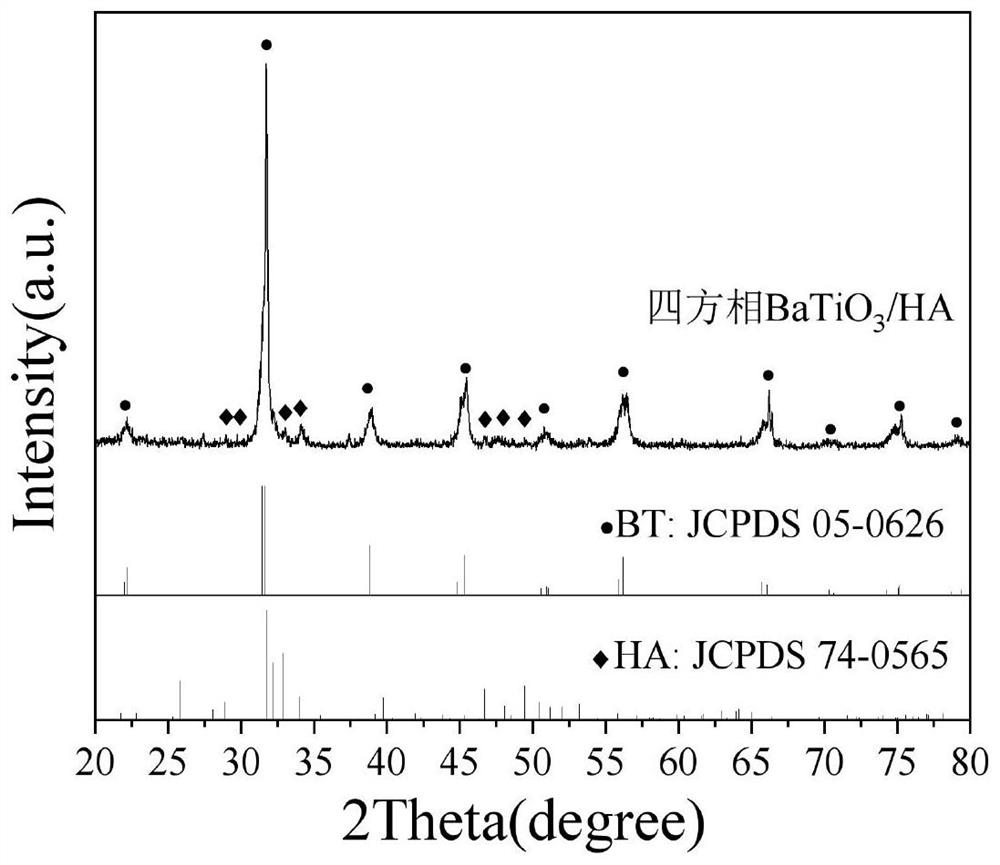

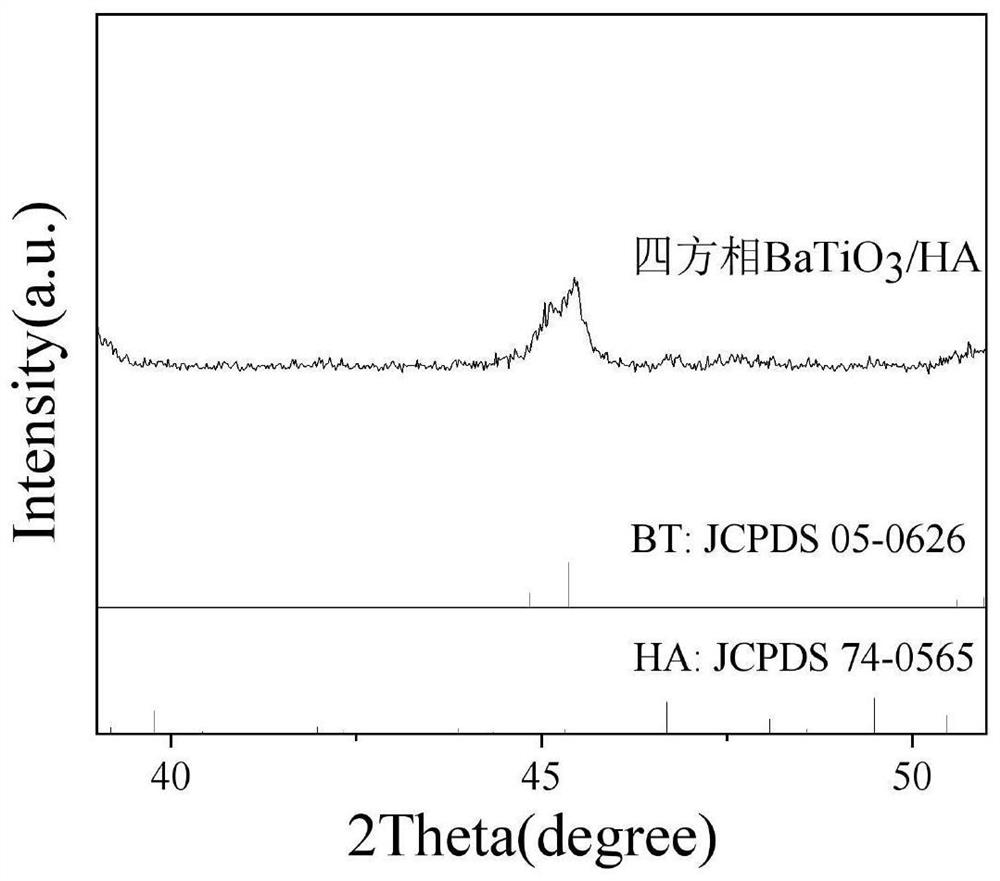

Examples

Embodiment 1

[0032] Step 1, preparation of BaTiO 3 Precursor solution: first weigh 1.8g BaCl 2 2H 2 Add 10mL of deionized water to O and stir until completely dissolved, then add 0.6g of ethanolamine into it, and stir evenly to obtain a barium salt solution; then weigh 3.5g of C 16 h 36 o 4 Dissolve Ti in 5mL of absolute ethanol, stir evenly to obtain a titanium salt solution; finally weigh 2.5g NaOH, slowly dissolve in 10mL deionized water one by one to obtain a strong alkali solution; mix the barium salt solution, titanium salt solution and strong alkali solution and stir evenly , to obtain a white turbid liquid, which is BaTiO3 precursor solution;

[0033]Step 2, preparing HA solution: Weigh 10g of commercial HA nanopowder and dissolve it in 50mL of absolute ethanol, stir evenly to obtain HA solution;

[0034] Step 3, preparation of BaTiO 3 / HA precursor solution: the BaTiO obtained in step 1 3 The precursor solution was mixed with the HA solution obtained in step 2, and stirred ...

Embodiment 2

[0038] Step 1, preparation of BaTiO 3 Precursor solution: first weigh 7.5g BaCl 2 2H 2 O was added with 30mL deionized water and stirred until it was completely dissolved, and another 1.8g ethanolamine was weighed into it, and stirred evenly to obtain a barium salt solution; then 10.5g C 16 h 36 o 4 Dissolve Ti in 15mL of absolute ethanol, stir evenly to obtain a titanium salt solution; finally weigh 7.5g NaOH, slowly dissolve in 30mL deionized water one by one to obtain a strong alkali solution; mix the barium salt solution, titanium salt solution and strong alkali solution and stir evenly , to obtain a white turbid liquid, which is BaTiO3 precursor solution;

[0039] Step 2, preparing HA solution: Weigh 10g of commercial HA nanopowder and dissolve it in 50mL of absolute ethanol, stir evenly to obtain HA solution;

[0040] Step 3, preparation of BaTiO 3 / HA precursor solution: the BaTiO obtained in step 1 3 The precursor solution is mixed with the HA solution obtained ...

Embodiment 3

[0044] Step 1, preparation of BaTiO 3 Precursor solution: first weigh 10.5g BaCl 2 2H 2 O was added with 60mL deionized water and stirred until completely dissolved, and another 3.6g ethanolamine was weighed into it, and stirred evenly to obtain a barium salt solution; then weighed 21g C 16 h 36 o 4 Dissolve Ti in 30mL of absolute ethanol, stir evenly to obtain a titanium salt solution; finally weigh 15g NaOH, slowly dissolve in 60mL deionized water one by one to obtain a strong alkali solution; mix the barium salt solution, titanium salt solution and strong alkali solution and stir evenly , to obtain a white turbid liquid, which is BaTiO3 precursor solution;

[0045] Step 2, preparation of HA solution: Weigh 10g of commercial HA nanopowder and dissolve it in 50mL of absolute ethanol, stir evenly to obtain HA solution;

[0046] Step 3, preparation of BaTiO 3 / HA precursor solution: the BaTiO obtained in step 1 3 The precursor solution was mixed with the HA solution obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com