A kind of preparation method of ultrahigh molecular weight anionic polyacrylamide

A technology of polyacrylamide and ultra-high molecular weight, which is applied in the field of preparation of polyacrylamide, can solve problems such as increase in specific surface area, loss of polymerization heat, low oxygen content, etc., and achieve increased specific surface area, lower content, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

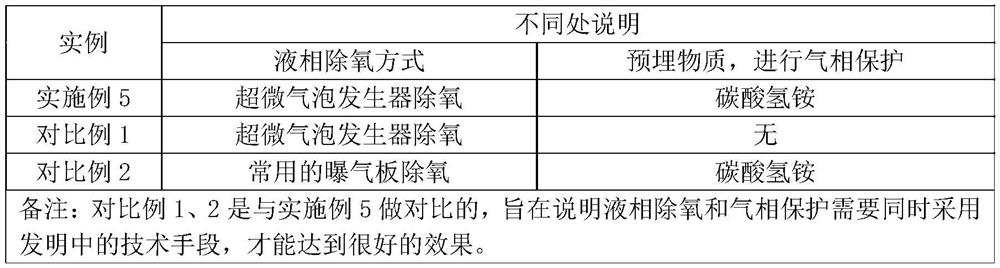

Examples

Embodiment 1

[0031] Embodiment 1: a kind of preparation method of the anionic polyacrylamide of ultrahigh molecular weight, comprises the following steps:

[0032] Step 1. Dissolve the raw material acrylamide and anionic monomer in water and adjust the pH value. In this embodiment, the anionic monomer includes one or two of acrylic acid, methacrylic acid and its sodium salt, and the pH value is adjusted to 5.5~ 6.5.

[0033] Step 2. Add photoinitiator, azo initiator, deoxidizer, metal chelating agent, metal chelating accelerator, cosolvent and chain transfer agent to the polymerization solution after adjusting the pH value in step 1. After stirring evenly, adjust again When the pH value of the polymerization solution is 5.5-6.5, the temperature of the polymerization solution is lowered to -10-5°C, and the oxygen content is reduced to <10ppb by means of a micro-bubble generator. In this embodiment, the oxygen content is preferably <2ppb. The polymer is put into the polymerization device wi...

Embodiment 2

[0047] Embodiment 2: In this embodiment, according to the preparation method of a kind of ultra-high molecular weight anionic polyacrylamide in embodiment 1, and prepare anionic polyacrylamide with the experimental data of specific numerical value, comprise the following steps:

[0048] Step 1. Add 4592kg of industrial grade acrylamide with a mass fraction of 30%, 344kg of anionic monomer methacrylic acid with a mass fraction of 70% and 1000kg of deionized water into the batching kettle, and use a mass fraction of 32%. NaOH adjusts the pH to 6.2;

[0049] Step 2, add the auxiliary material photoinitiator, azo initiator, deoxidizer, metal chelating agent, metal chelating accelerator, cosolvent and chain transfer agent into the batching kettle and mix evenly; preferably, the photoinitiator adopts 0.12kg 2-Hydroxy-2-methyl-1-[4-(2-hydroxyethoxy) phenyl]-1-propanone, the azo initiator adopts 0.24kg of azobisisobutylamidine hydrochloride and 1.2kg azodicyanovaleric acid, the deoxi...

Embodiment 3

[0053] Embodiment 3: In this embodiment, according to the preparation method of a kind of ultra-high molecular weight anionic polyacrylamide in embodiment 1, and prepare anionic polyacrylamide with the experimental data of specific numerical value, comprise the following steps:

[0054] Step 1. Add 3920kg of industrial-grade acrylamide with a mass fraction of 30%, 573.5kg of anionic monomer methacrylic acid with a mass fraction of 70%, and 1000kg of deionized water into the batching kettle, and use a mass fraction of 32%. NaOH to adjust the pH to 6.2;

[0055] Step 2, add the auxiliary material photoinitiator, azo initiator, deoxidizer, metal chelating agent, metal chelating accelerator, cosolvent and chain transfer agent into the batching kettle and mix evenly; preferably, the photoinitiator adopts 0.15kg 2-Hydroxy-2-methyl-1-[4-(2-hydroxyethoxy) phenyl]-1-propanone, the azo initiator adopts 0.18kg of azobisisobutylamidine hydrochloride and 1.0kg azodicyanovaleric acid, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com