Production process for extracting diosgenin

A technology for the production process of diosgenin, which is applied in the field of production process for extracting diosgenin, can solve the problems of long consumption time, low yield of diosgenin, and large acid consumption, so as to improve the extraction rate and purity, fully Effects of reusing resources and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

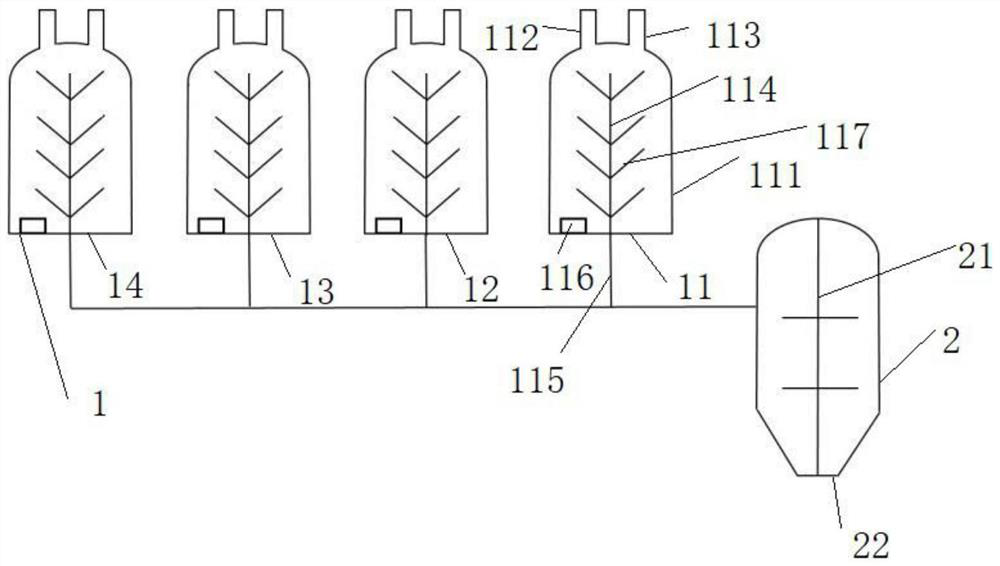

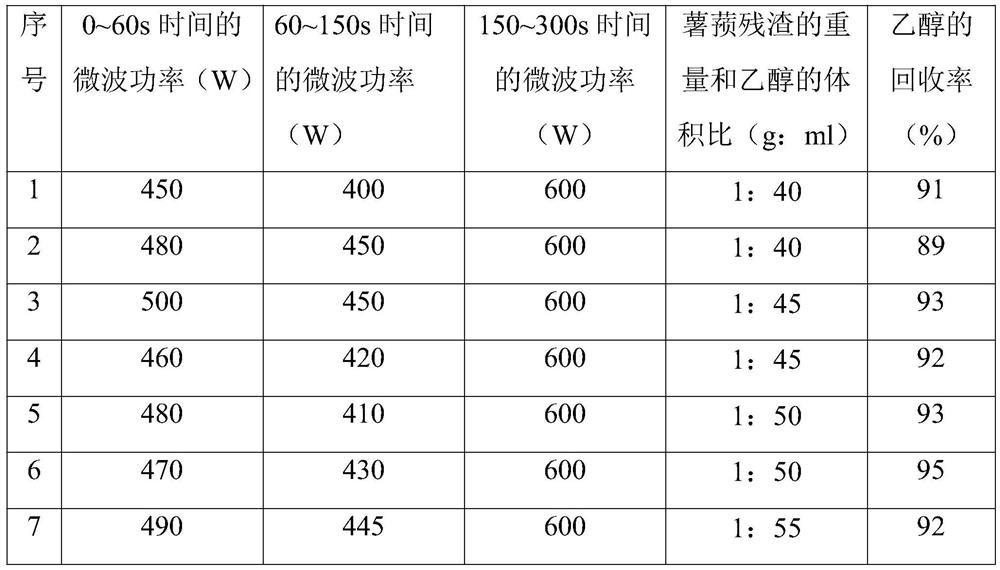

[0052] Take 1kg of fresh turmeric, wash it and cut it into 0.1-1cm thin sections, wash it with water, separate the starch and turmeric residue; add the turmeric residue into 70% ethanol solution, the volume of the ethanol solution is 50L , and then ultrasonic and microwave co-processing for 300s, the microwave power was 450W at 0-60s, 400W at 60-150s, and 600W at 150-300s; The material inlet is put into the first enzymolysis stirring tank, the second enzymolysis stirring tank, the third enzymolysis stirring tank and the fourth enzymolysis stirring tank, at the same time, add 4g α-glucosidase in the first enzymolysis stirring tank , and adjust the pH to 5.3, the temperature is 55 ° C, add 4 g rhamnosidase in the second enzymolysis stirring tank, and adjust the pH to 4.1, the temperature is 35 ° C, add 6 g glucuronic acid in the third enzymolysis stirring tank Glucosidase, and adjust the pH to 6.5, the temperature is 55 ° C, add 5 g of β-glucosidase to the fourth enzymolysis sti...

Embodiment 2

[0054] Take 1 kg of fresh yam yam, wash it, cut it into small sections with a thickness of 0.1 to 1 cm, wash it with water, and separate the starch and yam residue; add the yam residue to 70% ethanol solution, and The volume of the ethanol solution is 55L, and then ultrasonic and microwave synergistic treatment is carried out for 300s. The microwave power is 480W at 0-60s, 430W at 60-150s, and 600W at 150-300s; Divide into four parts, respectively put into the first enzymolysis stirring tank, the second enzymolysis stirring tank, the third enzymolysis stirring tank and the fourth enzymolysis stirring tank through the material inlet, at the same time, in the first enzymolysis stirring tank Add 4.5g α-glucuronidase, and adjust the pH to 5.0, the temperature is 51°C, add 4.8g glucuronidase to the second enzymolysis stirring tank, and adjust the pH to 7.0, the temperature is 56°C, the third enzyme Add 5.2g rhamnosidase to the stirred tank for enzymolysis, adjust the pH to 4.5, and...

Embodiment 3

[0056] Take 1 kg of fresh pangolin, wash it, cut it into 0.1-1cm thin sections, wash it with water, separate the starch and pangolin residue; add the pangolin residue into 70% ethanol solution, the volume of the ethanol solution is 48L , and then ultrasonic and microwave co-processing for 300s, the microwave power was 460W when 0-60s, the microwave power was 420W when 60-150s, and the microwave power was 600W when 150-300s; The material inlet is put into the first enzymolysis stirring tank, the second enzymolysis stirring tank, the third enzymolysis stirring tank and the fourth enzymolysis stirring tank, at the same time, add 4g β-glucosidase in the first enzymolysis stirring tank , and adjust the pH to 4.2, the temperature is 62°C, add 5.4g rhamnosidase in the second enzymolysis stirring tank, and adjust the pH to 4.3, the temperature is 50°C, add 5.8g glucose in the third enzymolysis stirring tank aldolidase, and adjust the pH to 6.5, and the temperature is 50°C, add 5g of α...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com