Light high-strength boron carbide particle reinforced aluminum-based composite material and preparation method thereof

A particle-reinforced aluminum and composite material technology, which is applied in the field of casting metal matrix composite materials, can solve the problems of cumbersome powder metallurgy operation, difficulty in large-scale mold size, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

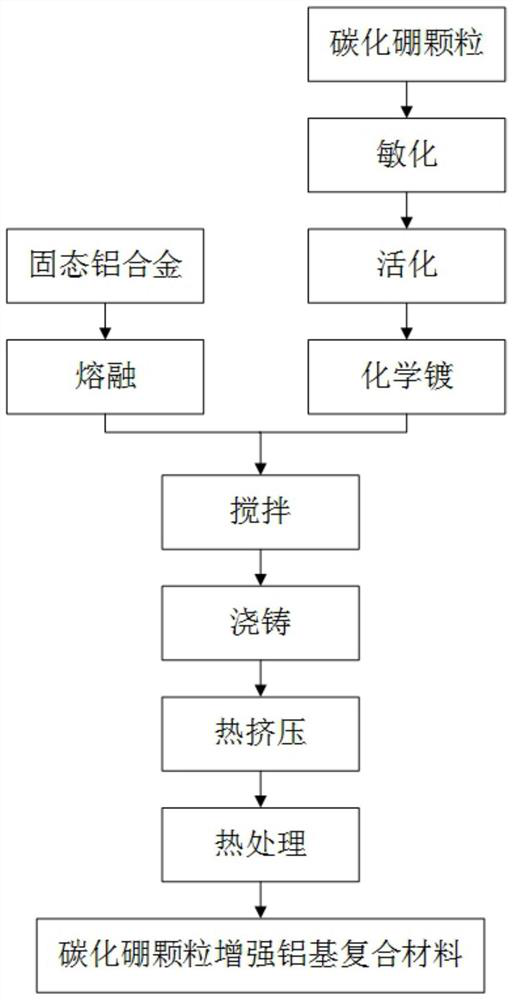

[0034] Example 1 according to figure 1 Prepared by the process shown, the composition of the composite material is 8 to 30% of boron carbide particles and 70 to 92% of the aluminum alloy matrix. The boron carbide particles used in Example 1 account for 12%, and the aluminum alloy matrix accounts for 88%. Copper plating is carried out on the particle surface, and copper plating includes sensitization, activation and electroless plating. Specific steps are as follows:

[0035] Sensitization treatment: put 1.2kg of boron carbide particles into 20L of SnCl 2 (30g / L) solution, stirred with a magnetic stirrer for 10min, poured off the supernatant after standing for a period of time, and washed with deionized water until neutral;

[0036] Activation treatment: Put the sensitized boron carbide particles into 20L of PdCl 2 (0.25g / L) solution, stirred with a magnetic stirrer for 10min, poured off the supernatant after standing for a period of time, and washed with deionized water unt...

Embodiment 2

[0047] Example 2 according to figure 1 In the preparation process shown, the boron carbide particles account for 8% by mass percentage, and the aluminum alloy matrix accounts for 92%. The specific steps are as follows:

[0048] Sensitization treatment: put 0.8kg boron carbide particles into 14L SnCl 2 (30g / L) solution, stirred with a magnetic stirrer for 10min, poured off the supernatant after standing for a period of time, and washed with deionized water until neutral;

[0049] Activation treatment: Put the sensitized boron carbide particles into 14L PdCl 2(0.25g / L) solution, stirred with a magnetic stirrer for 10min, poured off the supernatant after standing for a period of time, and washed with deionized water until neutral;

[0050] Electroless plating treatment: using the method of stirring and immersion plating, put the sensitized and activated boron carbide particles into a 14L copper plating solution, the pH value of the plating solution is 12.0, the temperature is 4...

Embodiment 3

[0057] Example 3 according to figure 1 According to the process shown in the preparation, the boron carbide particles account for 18% by mass percentage, and the aluminum alloy matrix accounts for 82%. The specific steps are as follows:

[0058] Sensitization treatment: put 1.8kg boron carbide particles into 30L SnCl 2 (30g / L) solution, stirred with a magnetic stirrer for 10min, poured off the supernatant after standing for a period of time, and washed with deionized water until neutral;

[0059] Activation treatment: Put the sensitized boron carbide particles into 30L of PdCl 2 (0.25g / L) solution, stirred with a magnetic stirrer for 10min, poured off the supernatant after standing for a period of time, and washed with deionized water until neutral;

[0060] Electroless plating treatment: using the method of stirring and immersion plating, put the sensitized and activated boron carbide particles into a 30L copper plating solution, the pH value of the plating solution is 12.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com