Silicon oxide, preparation method and application thereof

A silicon oxide, oxidizing environment technology, used in electrochemical generators, structural parts, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

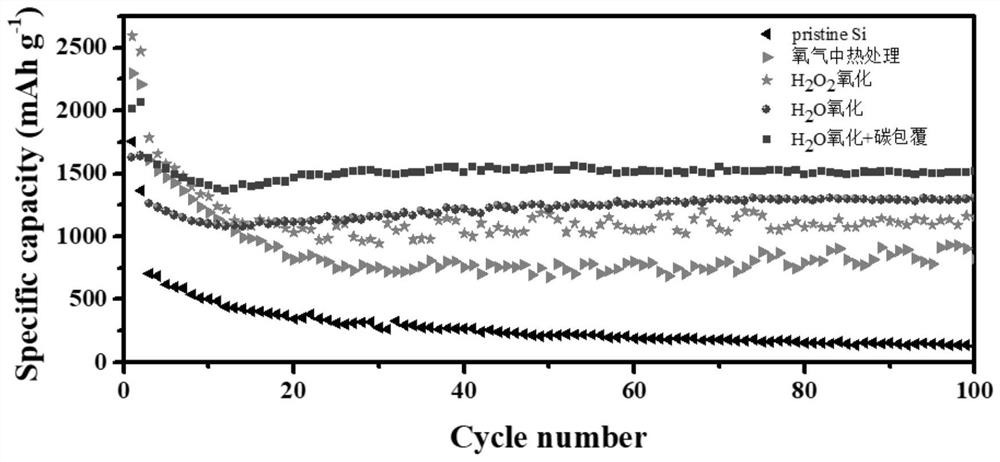

[0034] In this embodiment, the oxidation environment is oxygen gas, and the controllable oxidation is gas heat treatment.

[0035] (1) Surface treatment: put 5g of silicon powder in a beaker and place it in a fume hood, add 50mL of ultrapure water to it, then slowly add 30mL of HF solution with a mass fraction of 15% into the beaker, place the beaker on Stir and react on a stirring table for 12 hours; after the reaction, wash with ultrapure water and ethanol with a mass fraction of 97.5%, centrifuge three times, and then place it in a vacuum oven at 80°C to dry to obtain the silicon dioxide after the surface passivation layer is removed. Granular powder (pristine Si).

[0036] (2) Controlled oxidation: place the silicon material with fresh silicon surface in an oxygen atmosphere tube furnace for heat treatment. The heat treatment is 1000 ° C for 2 hours, and the temperature is cooled to room temperature to obtain silicon oxide (SiO x )Material.

Embodiment 2

[0038] In this embodiment, the oxidation environment is water, and the controllable oxidation is hydrothermal treatment.

[0039] (1) Surface treatment: Put 5g of silicon powder in a beaker and place it in a fume hood, add 50mL of ultrapure water to it, then slowly add 30mL of HF solution with a mass fraction of 15% into the beaker, place the beaker on Stir and react on a stirring table for 12 hours; after the reaction, wash with ultrapure water and ethanol with a mass fraction of 97.5%, centrifuge three times, and then place it in a blast drying oven at 80°C to dry to obtain the surface passivation layer after removal. silicon powder.

[0040] (2) Controlled oxidation: Disperse 1 g of silicon material with a fresh silicon surface into 20 mL of ultrapure aqueous solution, disperse evenly by ultrasonic, and stir for 15 min. Then, the solution was transferred to a hydrothermal reaction kettle with a capacity of 100 mL, sealed and reacted in an oven at 200° C. for 24 h.

[0041] ...

Embodiment 3

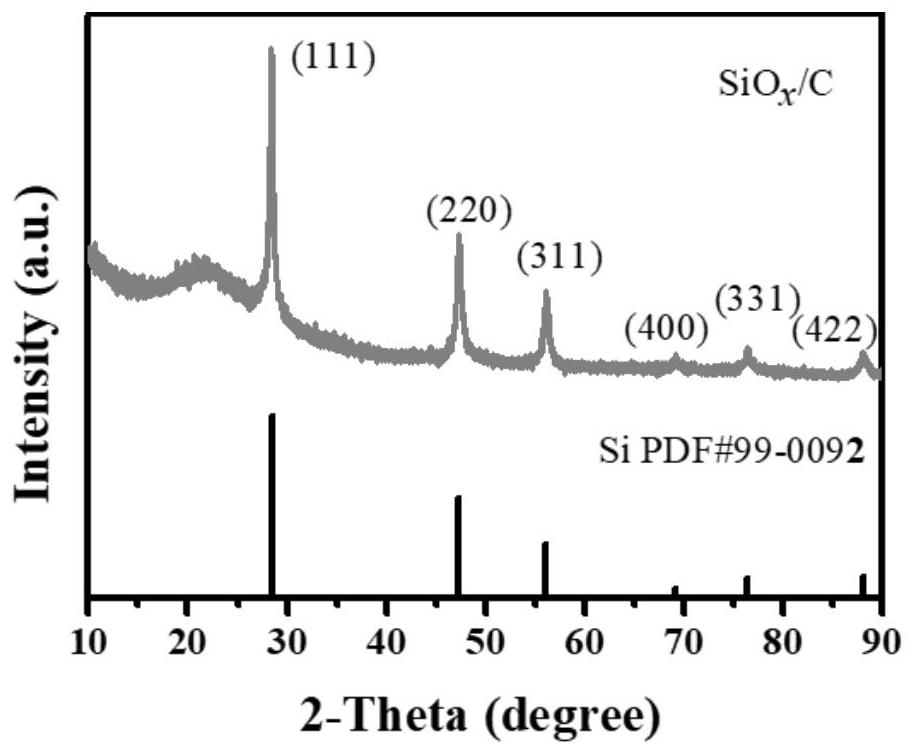

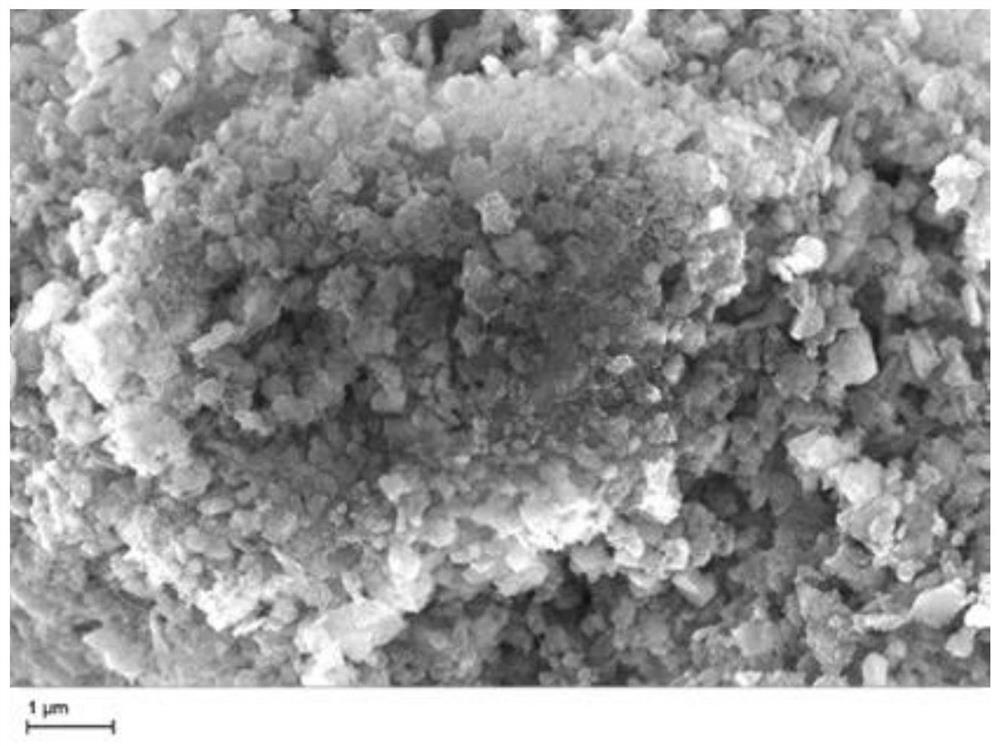

[0043] The difference between this example and Example 2 is that glucose is added as a carbon source for carbon coating during the controlled oxidation process, as described in detail.

[0044] (1) Surface treatment: Put 5g of silicon powder in a beaker and place it in a fume hood, add 50mL of ultrapure water to it, then slowly add 30mL of HF solution with a mass fraction of 15% into the beaker, place the beaker on Stir and react on a stirring table for 12 hours; after the reaction, wash with ultrapure water and ethanol with a mass fraction of 97.5%, centrifuge three times, and then place it in a blast drying oven at 80°C to dry to obtain the surface passivation layer after removal. silicon powder.

[0045] (2) Controllable oxidation: disperse 1g of silicon material with fresh silicon surface into 20mL ultrapure aqueous solution, obtain silicon suspension after ultrasonic dispersion, dissolve glucose particles in 20mL ultrapure aqueous solution to obtain glucose solution, pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com