High-adaptability polycarboxylate superplasticizer and preparation method thereof

A polycarboxylic acid, adaptable technology, applied in the field of concrete admixtures, can solve problems such as bleeding phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

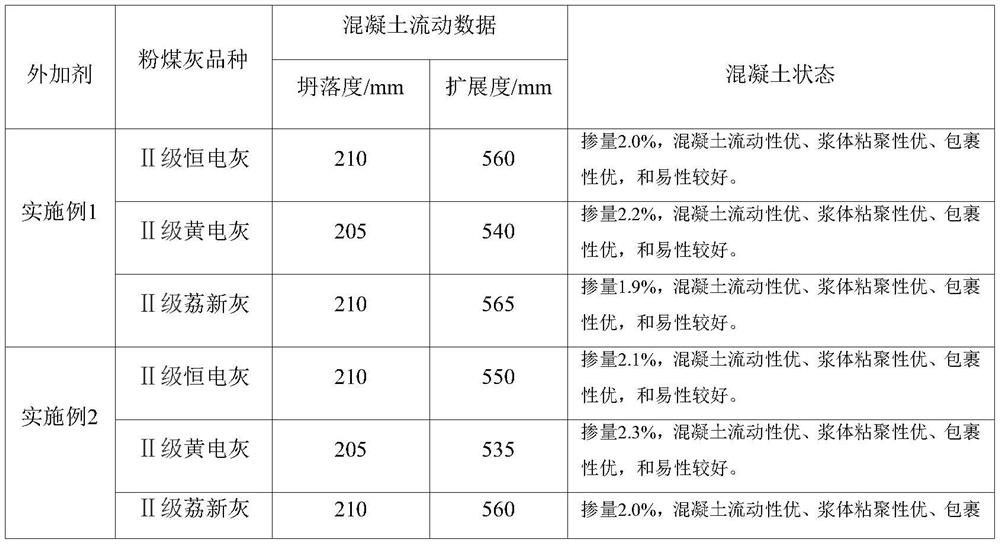

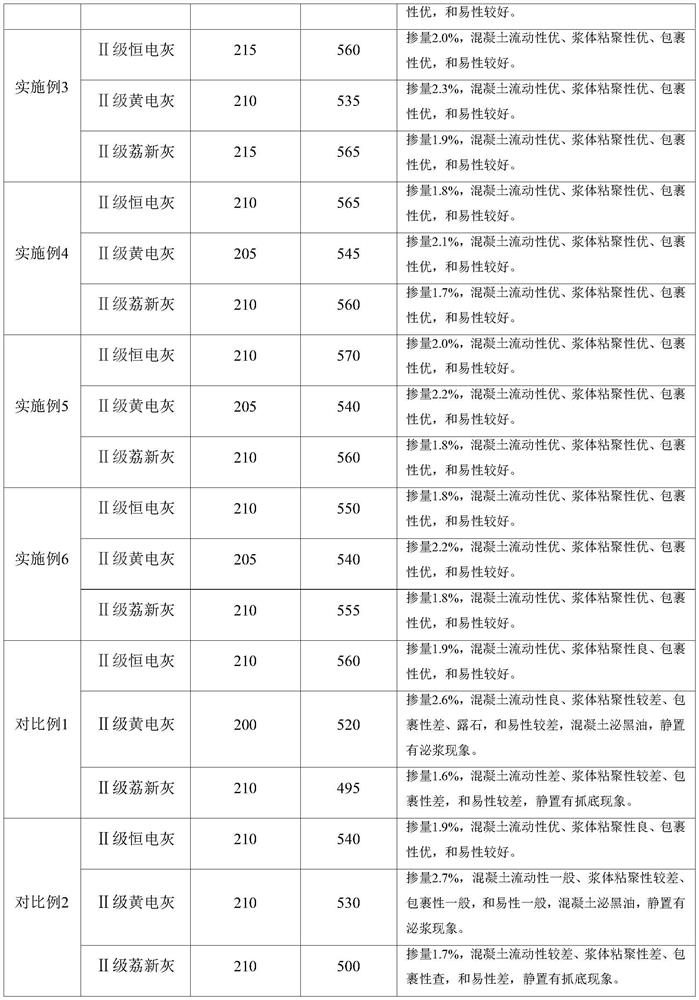

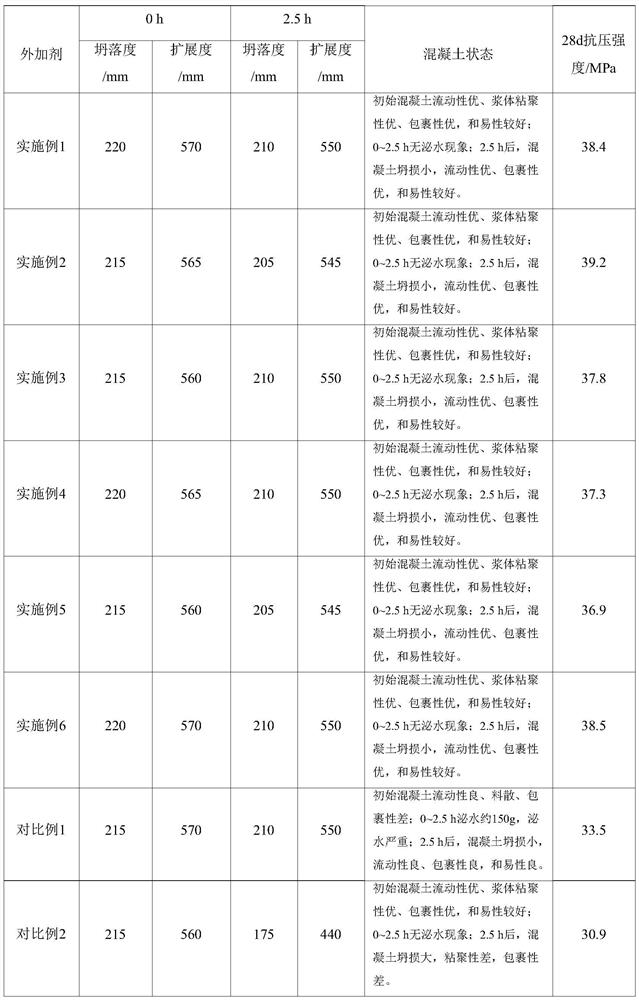

Examples

Embodiment 1

[0055] A highly adaptable polycarboxylate water reducer, consisting of the following raw materials in parts by mass:

[0056] 25 parts of polycarboxylic acid mother liquor;

[0057] Bleeding inhibitor 2 parts;

[0058] 2 parts retarder.

[0059] Wherein, the polycarboxylate mother liquor is prepared by the following method:

[0060] S1. Dissolve 350 parts of isopentenol polyoxyethylene ether with a relative molecular weight of 2400 in 350 parts of water, stir evenly at room temperature, and then add 3 parts of hydrogen peroxide to obtain the bottom liquid;

[0061] S2, 30 parts of acrylic acid, 20 parts of hydroxyethyl acrylate, 5 parts of 2-hydroxyethyl acrylate phosphate and 1 part of [2-(methacryloyloxy) ethyl] dimethyl-(3- Sulfonic acid propyl) ammonium hydroxide is dissolved in 44 parts of water, stirs evenly, obtains dropwise liquid DS1;

[0062] S3. Dissolve 1.8 parts of mercaptoethanol and 0.9 parts of sodium formaldehyde sulfoxylate in 100 parts of water, and stir...

Embodiment 2

[0068] A highly adaptable polycarboxylate water reducer, consisting of the following raw materials in parts by mass:

[0069] 25 parts of polycarboxylic acid mother liquor;

[0070] Bleeding inhibitor 1 part;

[0071] 2 parts retarder.

[0072] Wherein, the polycarboxylate mother liquor is prepared by the following method:

[0073] S1. Dissolve 350 parts of isopentenol polyoxyethylene ether with a relative molecular weight of 2400 in 350 parts of water, stir evenly at room temperature, then add 3 parts of sodium perchlorate to obtain the bottom liquid;

[0074] S2, 30 parts of acrylic acid, 20 parts of hydroxyethyl acrylate, 5 parts of 2-methyl-2-acrylic acid-2-hydroxyethyl phosphate and 1 part of [2-(methacryloyloxy) ethyl] Dimethyl-(3-sulfonic acid propyl)ammonium hydroxide was dissolved in 44 parts of water, and stirred evenly to obtain the dripping liquid DS1;

[0075] S3, 1.8 parts of mercaptoethanol and 0.9 parts of sodium bisulfite are dissolved in 100 parts of wate...

Embodiment 3

[0081] A highly adaptable polycarboxylate water reducer, consisting of the following raw materials in parts by mass:

[0082] 25 parts of polycarboxylic acid mother liquor;

[0083] Bleeding inhibitor 1 part;

[0084] 2 parts retarder.

[0085] Wherein, the polycarboxylate mother liquor is prepared by the following method:

[0086] S1. Dissolve 350 parts of prenol polyoxyethylene ether with a relative molecular weight of 2400 in 350 parts of water, stir evenly at room temperature, and then add 3 parts of hydrogen peroxide to obtain the bottom liquid;

[0087] S2. Dissolving 30 parts of acrylic acid, 20 parts of hydroxyethyl acrylate, 5 parts of 2-methyl-2-acrylic acid-2-hydroxyethyl phosphate and 1 part of methacryloyloxyethyltrimethylammonium chloride In 44 parts of water, stir evenly to obtain dropwise solution DS1;

[0088] S3, 1.2 parts of thioglycolic acid and 1.0 part of L-ascorbic acid are dissolved in 100 parts of water, and stirred evenly to obtain the dripping li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap