Continuous ion exchange method for separating lithium from salt lake brine

A salt lake brine and separation technology, applied in the field of continuous separation and separation, can solve the problems of low utilization rate and utilization efficiency of adsorption materials, long process operation process, high production and treatment costs, etc., achieve target ion yield improvement, simple automatic control system, The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

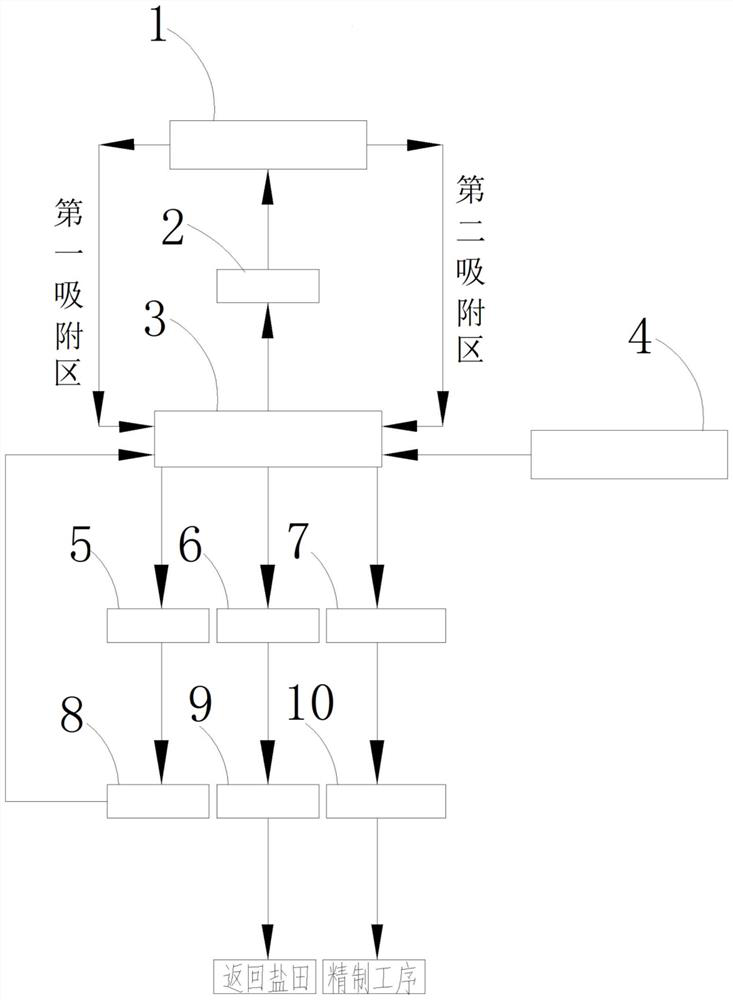

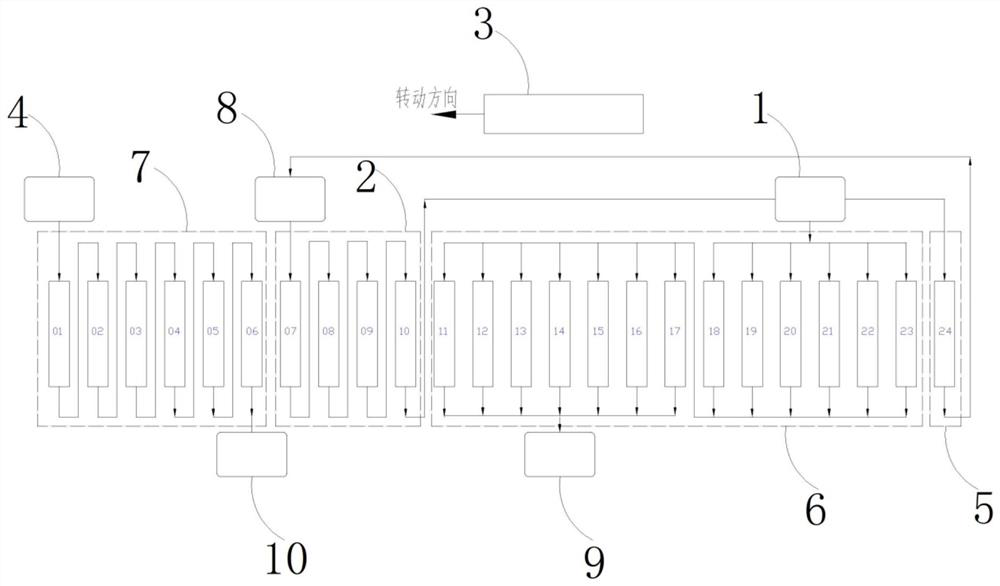

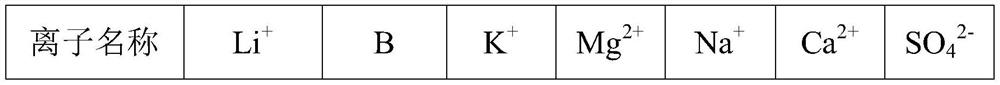

[0060]figure 1 withfigure 2 In the first suction zone resin column set, 1 group, 1 of the second suction zone resin column, and the first group is 6 resin columns, and the second group is 7, the top fluid zone resin. The column is 1 group, which is 4 resin columns, and the resin column is 1 group, each group of 6 resin columns. The temperature of 15 ° C is used in a temperature of 15 ° C, which is derived from a temperature of 15 ° C which is 15 ° C which is 15 ° C medium, and the temperature of 15 ° C is a pyrolysis liquid, and the valve is passed through the center rotation valve, respectively. Valve switching time is 15 minutes) The corresponding first adsorption region feed tube (24 #), the second adsorption region feed tube (11-23 #), a top-liquid feed tube (7-10 #), analytical liquid feed After the tube (1-6 #) enters the corresponding resin column, the entire process is achieved from the corresponding number of discharge tubes, respectively.

[0061]1. The first adsorption regio...

Embodiment 2

[0069]The feed temperature and the center rotation valve switching time were used in the same manner as in Example 1, respectively, respectively, and each liquid phase composition was shown in Table 4.

[0070]1. The first adsorption region control feed flow rate is controlled at 0.35 bv / h to obtain an adsorption tail solution to recovery into a top-liquid storage tank.

[0071]2, the second adsorption region controls the feedstream flow rate to adsorb in 2.2bv / h, adsorbing the tail liquid L2-1 discharge tail liquid storage, and finally returned to the salt field, the recovery of lithium in the second adsorption region was 86.2%.

[0072]3, the top fluid zone control feed flow rate control is controlled at 1.6 bv / h to carry out the top fluid, and the topcogen is returned to the brine storage tank again.

[0073]4, the desorption liquid region control the feed flow rate control at 1.5 bv / h, using pure water as a parsing medium, and the obtained analytical solution L2-2 medium is used as ...

Embodiment 3

[0075]The feed temperature and the center rotation valve switching time were used in the same manner as in Example 1, respectively, respectively, and each liquid phase composition was shown in Table 4.

[0076]1. The first adsorption region controls the feedstream flow rate to adsorb at 0.6 bv / h, and the adsorption tail is recovered to the top liquid storage tank.

[0077]2, the second adsorption area controls the feedstream flow rate control at 3 BV / h to adsorb the tail liquid L3-1 emissions tail liquid storage, and finally returned to the salt field, the recovery of lithium in the second adsorption region is 84.14%.

[0078]3, the top fluid zone control feed flow rate control is carried out in 2BV / H to return to the brine storage tank again.

[0079]4, the desorption liquid region controls the feedstream flow rate control at 2BV / H to perform a top fluid, and the pure water is used as the parsing medium, and the obtained analytical solution L3-2 medium is used as the product fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com