Preparation method of MCrAlY alloy material with yttrium elements distributed uniformly

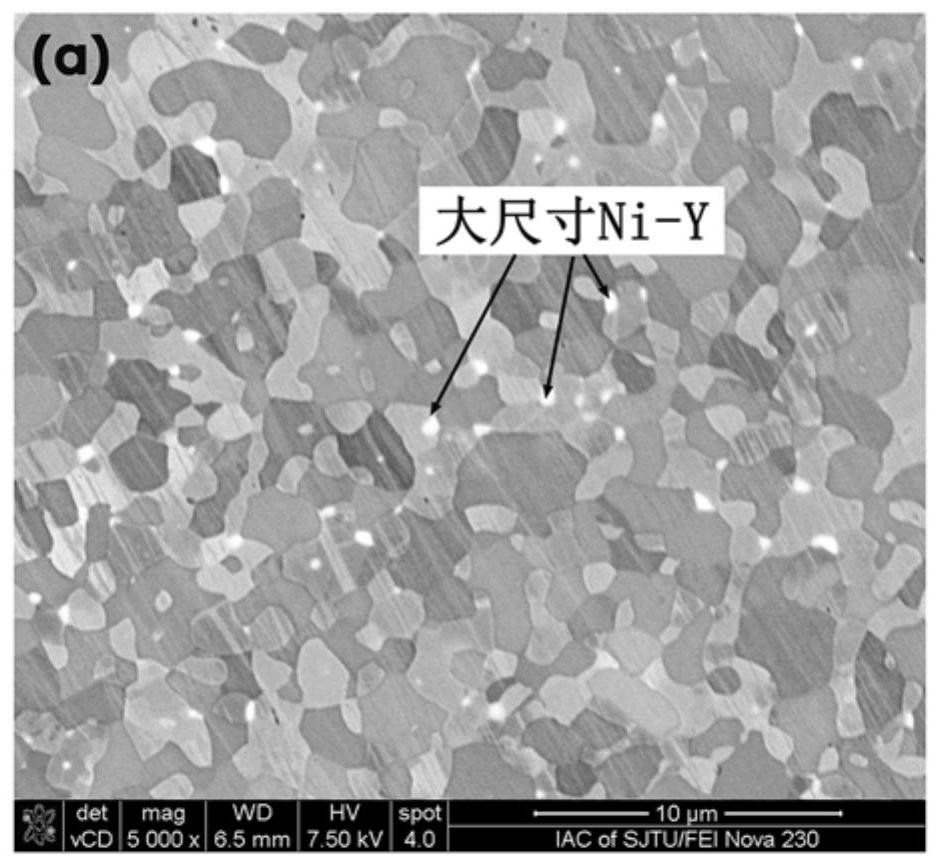

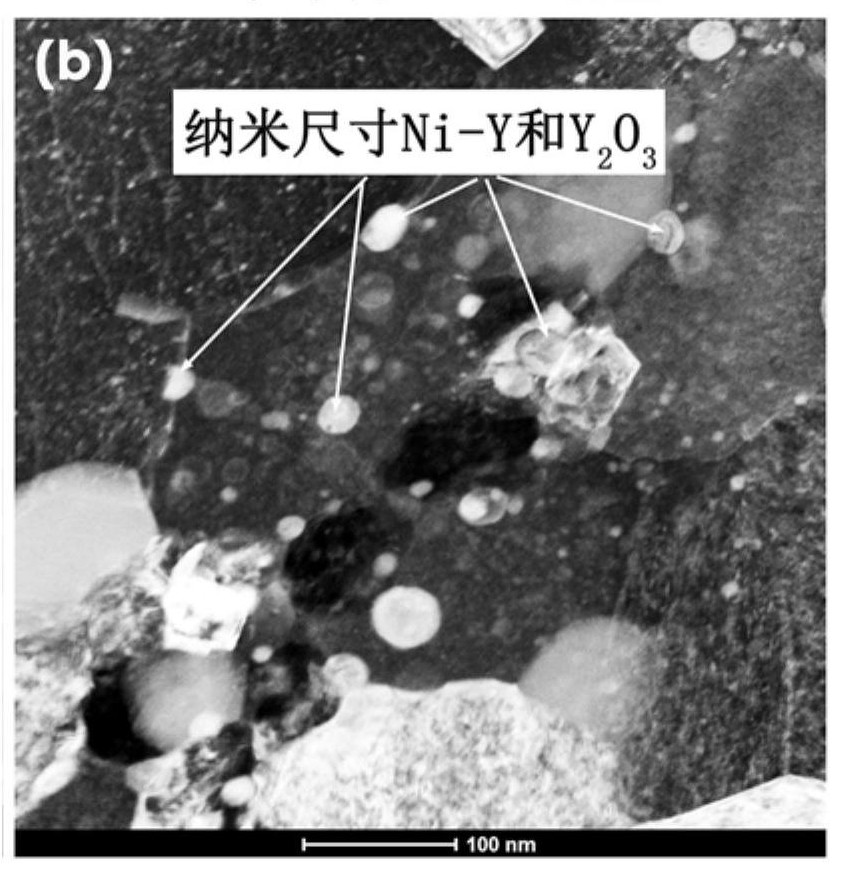

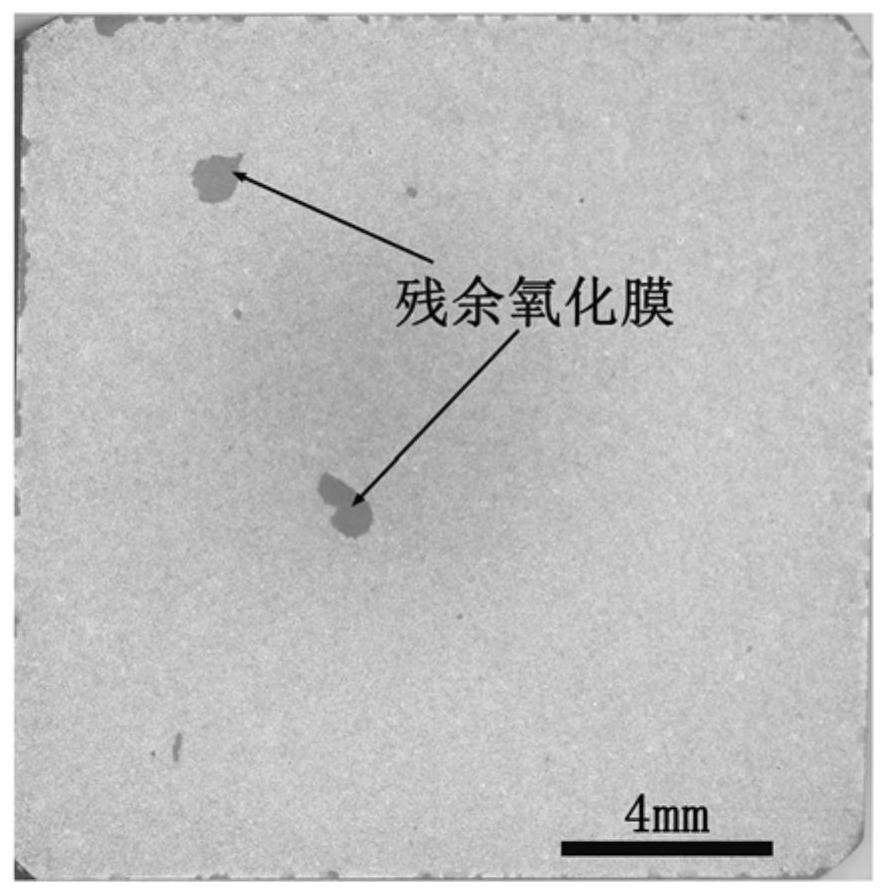

A technology of alloy material and element uniformity, applied in the field of surface engineering, can solve the problems of excessive oxide doping, Y-enriched oxide interface defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put a total of 100g of commercial NiCrAlY spray powder with a particle size of 46-85μm into a vacuum glove box, and put it into a 250ml ball mill jar under the protection of an argon atmosphere. The ball mill jar needs to be protected by argon gas. The composition ratio of the powder is Ni 47.5wt%; Co23wt%; Cr 17wt%; Al 12wt%; Y 0.5wt%.

[0033] Commercial MCrAlY spray powders were ball milled by a planetary ball mill. The speed of the ball mill is 400 rpm, the ball milling time is 24 hours, the ball-to-material ratio is 12:1, and the balls are high-hardness 440C stainless steel balls. And during the ball milling process, stop for 20 minutes every hour to prevent the temperature from being too high.

[0034] Spark plasma sintering was performed on the ball milled powder prepared by ball milling. Under vacuum conditions, the temperature is raised to 1050°C at a heating rate of 100°C / min, the holding time is 10 minutes under a pressure of 50MPa, and the cooling time is ...

Embodiment 2

[0038] Put a total of 200g of commercial NiCrAlY spray powder with a particle size of 46-85μm into a vacuum glove box, and put it into a 250ml ball mill jar under the protection of an argon atmosphere. The ball mill jar needs to be protected by argon. The composition ratio of the powder is Ni 47.5wt%; Co23wt%; Cr 17wt%; Al 12wt%; Y 0.5wt%.

[0039] Commercial MCrAlY spray powders were ball milled by a planetary ball mill. The rotating speed of the ball mill is 400 rpm, the ball milling time is 24 hours, and the ball-to-material ratio is 10:1. And during the ball milling process, stop for 20 minutes every hour to prevent the temperature from being too high.

[0040] Spark plasma sintering was performed on the ball milled powder prepared by ball milling. Under vacuum conditions, the temperature is raised to 1050°C at a heating rate of 100°C / min, the holding time is 10 minutes under a pressure of 50MPa, and the cooling time is 30 minutes, so that the MCrAlY alloy with uniform d...

Embodiment 3

[0044] 46-85 μm commercial NiCrAlY spraying powder (the composition ratio of powder is Ni 47.5wt%; Co23wt%; Cr 17wt%; Al 12wt%; Y 0.5wt%) a total of 200g is put into a stainless steel vacuum ball mill tank, and then Add high-hardness 440C stainless steel balls at a ratio of 5:1, and add stearic acid seat ball milling media with a ratio of 0.05wt.%. Move the filled ball mill tank into a vacuum glove box, and use high-purity argon gas to repeatedly wash gas three times. After the gas washing is completed, seal the ball mill tank inside the glove box, and then remove it from the glove box. The sealed ball mill jar was fixed on a planetary ball mill for ball milling; the rotating speed of the ball mill was 300 rpm, and the ball milling time was 96 hours. And stop for 20 minutes every hour during the ball milling process to prevent the temperature from being too high;

[0045] Sieve the ball-milled NiCoCrAlY powder to a particle size range of 45-75μm, put the sieved powder into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com