Method for preparing perovskite QLED electron transport layer by transferring ZnO nano-film

A technology of electron transport layer and nano-thin film, which is applied in the direction of circuits, electrical components, electric solid devices, etc., to achieve the effect of reducing damage and making the process simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

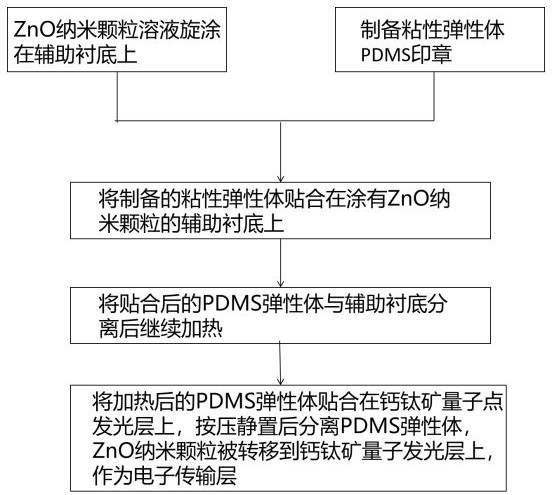

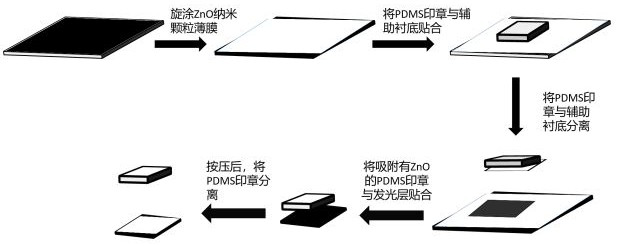

[0028] Schematic diagram of the process flow of a method of transferring ZnO nanoparticles to prepare the electron transport layer of perovskite QLED, as shown in figure 1 shown. Specifically include the following steps:

[0029] (1) First prepare the elastomeric PDMS stamp: coat a layer of polydimethylsiloxane (PDMS) on the glass substrate, and the area of the PDMS stamp is 1cm 2 And the thickness is 7mm, and then it is heated for 20 minutes to make it in an incompletely cured state with viscosity, and the annealing temperature is 80°C.

[0030] Among them, PDMS is mixed with a liquid component and a curing agent in a mass ratio of 10:1, and then stirred for 10 minutes, then put it in a vacuum drying oven to evacuate it, and take it out after standing for 0.5 hours, and discharge the dissolved air.

[0031] (2) Preparation of ZnO nanoparticle solution, first dissolve 0.59g of zinc acetate in 25ml of methanol, then heat and stir in a water bath with a temperature of 63°C-6...

Embodiment 2

[0035] (1) Preparation of elastomeric PDMS stamp: Coating a layer of polydimethylsiloxane (PDMS) on polyethylene terephthalate (PET), the area of the PDMS stamp is 1cm 2 And the thickness is 7mm, and then it is heated for 20 minutes to make it in an incompletely cured state with viscosity, and the annealing temperature is 80°C.

[0036] Among them, PDMS is mixed with a liquid component and a curing agent in a mass ratio of 10:1, then stirred for 10 minutes, then put it in a vacuum drying oven to evacuate it, let it stand for 0.5 hours, and then take it out to discharge the dissolved air.

[0037] (2) Preparation of ZnO nanoparticle solution, first dissolve 0.59g of zinc acetate in 25ml of methanol, then heat and stir in a water bath with a temperature of 63°C-65°C. At the same time, dissolve 0.3g of potassium hydroxide in 13ml of methanol, heat in a water bath at the same temperature for 5 minutes, then drop the potassium hydroxide solution into the zinc acetate solution, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com