Method for reducing industrial sludge and improving dehydration performance of industrial sludge

A technology for industrial sludge and dehydration performance, applied in water/sludge/sewage treatment, sludge treatment, sludge oxidation treatment, etc., can solve problems affecting the normal operation of biochemical systems, secondary pollution, high equipment requirements, etc., to achieve Saving sludge dewatering operating costs, saving disposal costs, and obvious effects of sludge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

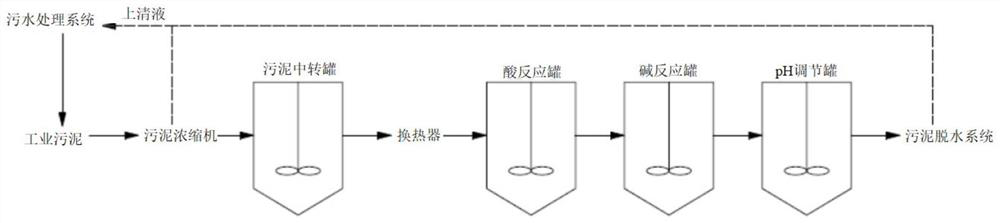

Image

Examples

Embodiment 1

[0079] The treatment of physical, chemical, biochemical and mixed industrial sludge with a solid content of 2% in a chemical plant in Nantong includes the following steps:

[0080] S1, transfer the industrial sludge with a solid content of 2% to a sludge thickener to increase the solid content of the industrial sludge to 4%.

[0081] S2, the concentrated industrial sludge with a solid content of 4% is transferred to the sludge transfer tank until the entire sludge transfer tank (corresponding to the high liquid level 650L of the sludge transfer tank) is filled, with a stirring speed of 50rpm Stir it evenly, and the stirring time is 60min.

[0082] S3, passing the uniformly stirred industrial sludge into the heat exchanger to raise the temperature of the industrial sludge to 60°C.

[0083] S4, transfer the industrial sludge at a temperature of 60° C. to an acid reaction tank for acid reaction.

[0084] In step S4, further comprising the following steps:

[0085] S4.1, during...

Embodiment 2

[0101] The method of embodiment 2 is identical with embodiment 1, and its difference is only in:

[0102] (1) In step S1, the solid content of the industrial sludge is increased to 5%.

[0103] (2) In step S2, the stirring speed is 70 rpm, and the stirring time is 50 min.

[0104] (3) In step S3, the industrial sludge is heated up to 70°C.

[0105] (4) In step S4.1, add sulfuric acid with a concentration of 35wt% to the acid reaction tank, the stirring speed is 70rpm, and the industrial sludge is kept at 70°C;

[0106] In step S4.2, the pH is 2.2;

[0107] In step S4.3, the concentration of hydrogen peroxide is 31wt%, and the dosing quality of hydrogen peroxide is 0.08g / g industrial sludge dry weight, and the dosing time (being reaction time) of hydrogen peroxide is 75min, and the dosing ratio of hydrogen peroxide is 8 %, the feeding rate of the hydrogen peroxide dosing pump is 2.08L / h.

[0108] (5) In step S5.1, dosing concentration is 35wt% sodium hydroxide in alkali rea...

Embodiment 3

[0115] The method of embodiment 3 is identical with embodiment 1, and its difference is only in:

[0116] (1) In step S1, the solid content of the industrial sludge is increased to 8%.

[0117] (2) In step S2, the stirring speed is 80 rpm, and the stirring time is 40 min.

[0118] (3) In step S3, the temperature of industrial sludge is raised to 80°C.

[0119] (4) In step S4.1, add sulfuric acid with a concentration of 45wt% to the acid reaction tank, the stirring speed is 80rpm, and the industrial sludge is kept at 80°C;

[0120] In step S4.2, the pH is 2.4;

[0121] In step S4.3, the concentration of hydrogen peroxide is 32wt%, and the dosing quality of hydrogen peroxide is 0.09g / g industrial sludge dry weight, and the dosing time (being reaction time) of hydrogen peroxide is 80min, and the dosing ratio of hydrogen peroxide is 9 %, the feeding speed of the hydrogen peroxide dosing pump is 3.51L / h.

[0122] (5) In step S5.1, dosing concentration is 45wt% sodium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com