Liquefied petroleum gas sweetening composite solvent as well as preparation method and application thereof

A technology of liquefied petroleum gas and composite solvent, which is applied in the petroleum industry, the processing of gas mixtures, gas fuel, etc., can solve the problems of shortened cycle life of the extractant, reduced alkali content in the circulation system, and slow regeneration of the extractant, etc. Achieve the effects of avoiding co-solvent loss, increasing operating costs, economic benefits and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

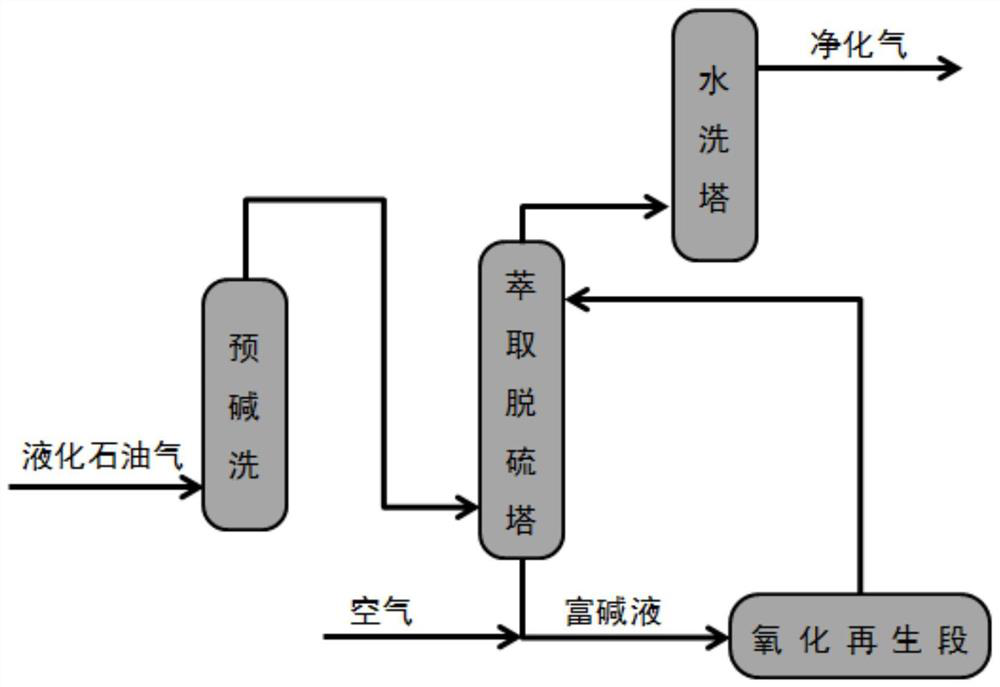

Method used

Image

Examples

Embodiment 1-13 and comparative example 1-4

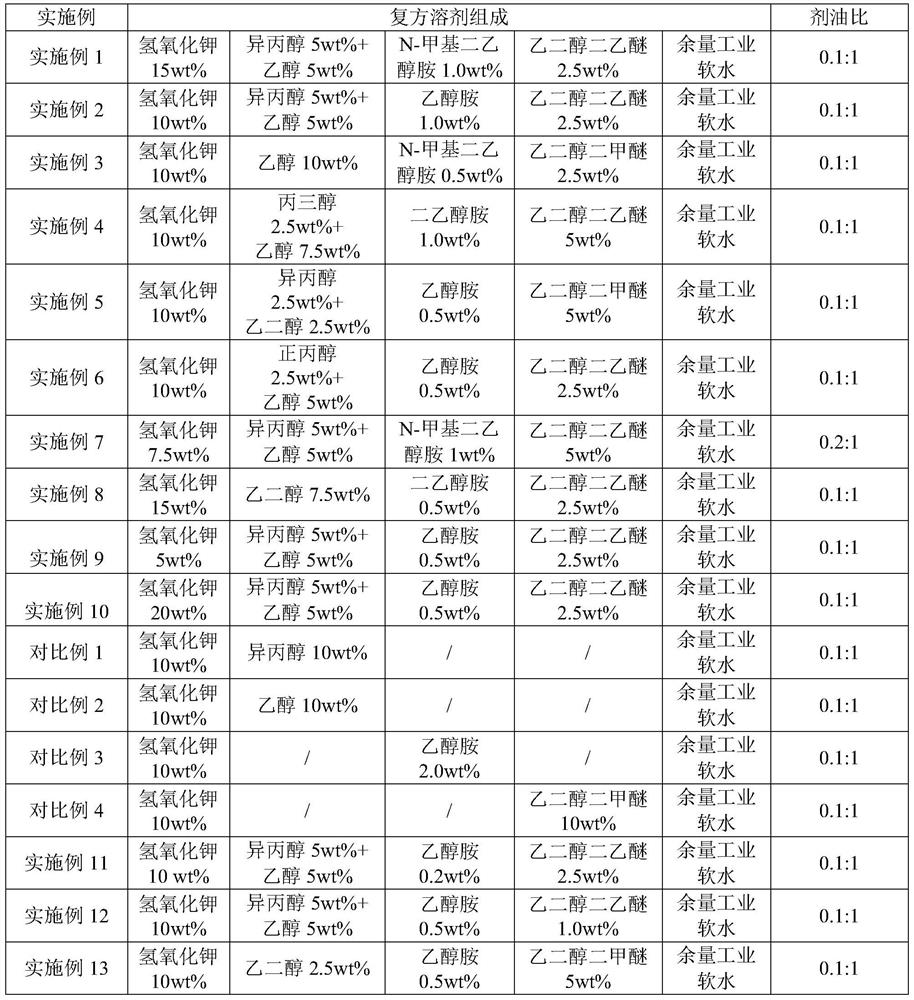

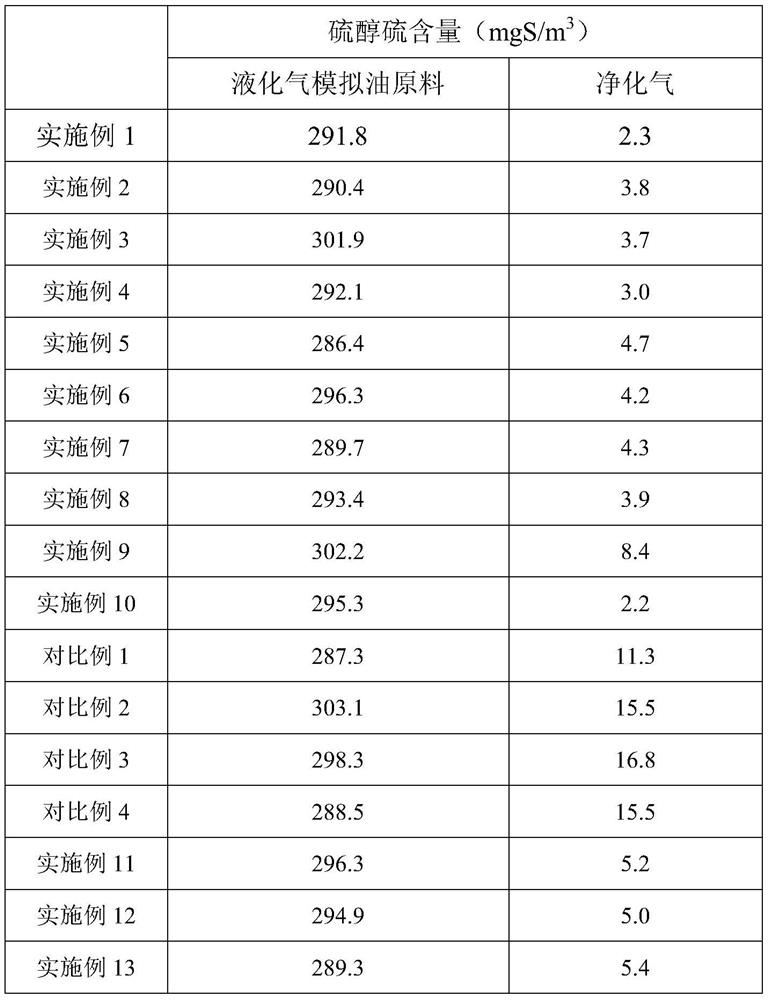

[0047] 1. The formulations of the liquefied petroleum gas sweetening composite solvents of the various examples and comparative examples are shown in Table 1.

[0048] 2. The liquefied petroleum gas sweetening compound solvent of each embodiment agent is obtained with reference to the following preparation process:

[0049] According to the composite solvent formula, in the reaction kettle, dissolve alcohol additives in a part of industrial soft water to form an aqueous solution of alcohol additives, then add alcohol amine additives and ether additives in sequence, and stir evenly to obtain a mixed Solution; the inorganic strong base is dissolved in the remaining part of the industrial soft water to form an aqueous solution of the inorganic strong base, and the aqueous solution of the inorganic strong base is added to the above mixed solution, and in N 2 Stir vigorously under a protective atmosphere to make it evenly mixed to obtain a composite solvent; the process is carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com