Method for pre-processing corn straw with supercritical carbon dioxide coupled with NaOH to enhance xylose conversion efficiency through enzymatic hydrolysis

A technology for carbon dioxide and corn stalks, which is applied in the production and fermentation of bulk chemicals, can solve the problems of the separation and utilization of lignocellulose, the structure of lignocellulose is extremely complex, and the pretreatment effect of lignocellulose is limited. Enzymatic hydrolysis efficiency, simple and convenient pretreatment methods, and the effect of improving the efficiency of enzymatic catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

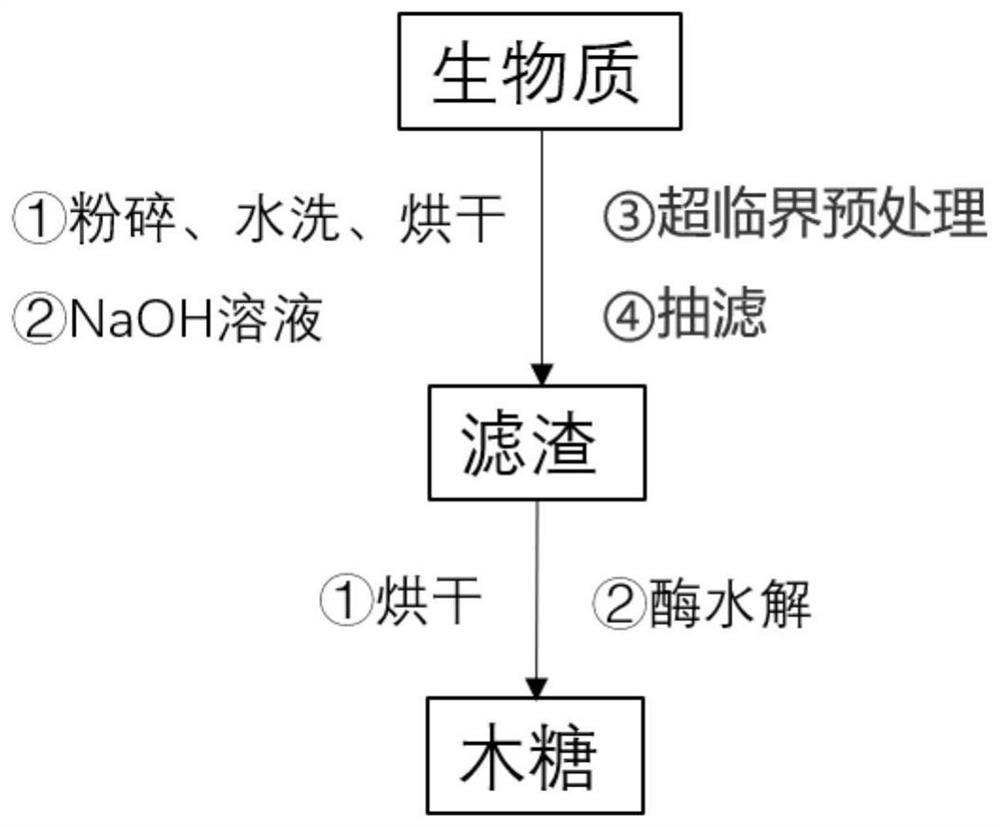

[0026] The method for pretreating corn stalks with supercritical carbon dioxide coupled with NaOH to improve the efficiency of enzymatic hydrolysis and conversion of xylose comprises the following steps:

[0027] (1) After crushing, washing and drying corn stalks to obtain corn stalk powder, take 50g of corn stalk powder and add it to 500ml of 1wt% NaOH solution, stir evenly to obtain a mixture;

[0028] (2) Put the mixture in supercritical CO 2 Pretreatment for 60 minutes under the same conditions, the pretreatment temperature is 35 ℃;

[0029] (3) Suction filter the pretreated mixture through a non-woven fabric to obtain filtrate and filter residue, use 1000ml of deionized water to wash the filter residue, put the washed filter residue into an oven at 45°C and dry for 12 hours;

[0030] (4) Get 2g dried filter residue and put it into 100ml of trisodium citrate buffer, the pH of trisodium citrate buffer is 5, and add 0.625g of acid xylanase in trisodium citrate buffer , enz...

Embodiment 2

[0033] The method for pretreating corn stalks with supercritical carbon dioxide coupled with NaOH to improve the efficiency of enzymatic hydrolysis and conversion of xylose comprises the following steps:

[0034] (1) After crushing, washing and drying corn stalks to obtain corn stalk powder, take 50g of corn stalk powder and add it to 500ml of 1wt% NaOH solution, stir evenly to obtain a mixture;

[0035] (2) Put the mixture in supercritical CO 2 Pretreatment for 60 minutes under the same conditions, the pretreatment temperature is 50 ℃;

[0036] (3) Suction filter the pretreated mixture through a non-woven fabric to obtain filtrate and filter residue, use 1000ml of deionized water to wash the filter residue, put the washed filter residue into an oven at 45°C and dry for 12 hours;

[0037] (4) Get 2g dried filter residue and put it into 100ml of trisodium citrate buffer, the pH of trisodium citrate buffer is 5, and add 0.625g of acid xylanase in trisodium citrate buffer , enz...

Embodiment 3

[0040] The method for pretreating corn stalks with supercritical carbon dioxide coupled with NaOH to improve the efficiency of enzymatic hydrolysis and conversion of xylose comprises the following steps:

[0041] (1) After crushing, washing and drying corn stalks to obtain corn stalk powder, take 50g of corn stalk powder and add it to 500ml of 1wt% NaOH solution, stir evenly to obtain a mixture;

[0042] (2) Put the mixture in supercritical CO 2 Pretreatment for 60 minutes under the same conditions, the pretreatment temperature is 70 ℃;

[0043] (3) Suction filter the pretreated mixture through a non-woven fabric to obtain filtrate and filter residue, use 1000ml of deionized water to wash the filter residue, put the washed filter residue into an oven at 45°C and dry for 12 hours;

[0044] (4) Get 2g dried filter residue and put it into 100ml of trisodium citrate buffer, the pH of trisodium citrate buffer is 5, and add 0.625g of acid xylanase in trisodium citrate buffer , enz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com