Chocolate popping beads, fruity sauce containing chocolate popping beads and preparation method thereof

A chocolate and fruit jam technology, applied in dairy products, milk preparations, cocoa, etc., can solve the problems of low melting point and high fat content of chocolate raw materials, and achieve good flavor release, moderate viscosity and fluidity, and high uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a kind of preparation method of chocolate quick-fried bead, and this preparation method comprises the following steps:

[0031] Step 1: Put the popping beads wrapping solution in the vibrating sieve, so that the popping beads wrapping solution circulates from the top of the vibrating sieve to the bottom;

[0032] Step 2: Drip the center liquid of the popping beads downward at a pressure of 0.02 to 0.08 bar, and condense the center liquid of the popping beads dripped into the wrapping skin solution of the popping beads to form popping beads.

[0033] Exemplarily, firstly, put the popping beads coating solution in a vibrating screen with an inclination angle of 4-5°, the length of the vibrating screen is 2-3m, and circulate through the rotor pump so that the popping beads coating solution is continuously circulated from the top of the vibrating screen to the bottom flow; then, the center solution of the popping beads is dripped from the perf...

Embodiment 1

[0068] Preparation of S1 Bead Center Solution:

[0069] After heating the purified water to 40°C, add stabilizer, sweet sugar, chocolate natural ingredients and food flavors, etc., stir at 50rpm for 10 minutes, then cool to 20°C for later use, storage time ≤ 15h, the content of each ingredient The amount added is shown in the table below:

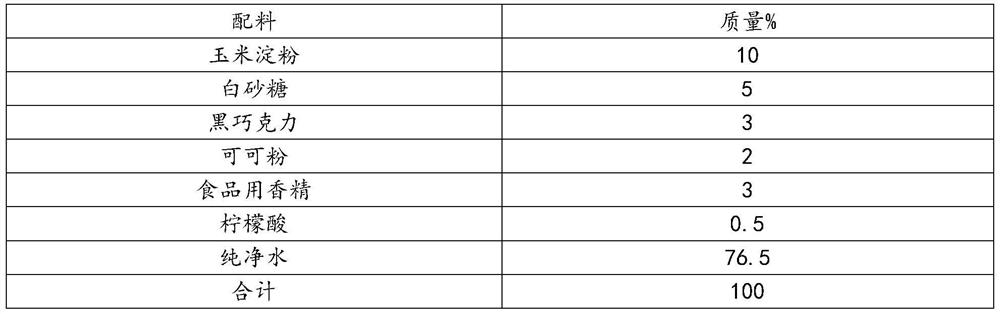

[0070] The composition formula of the quick-fried pearl central liquid of table 1 embodiment 1

[0071]

[0072]

[0073] Preparation of S2 bead wrapping skin:

[0074] Raise the temperature of purified water to 70°C, add a stabilizer, and stir and circulate at 800rpm for 20 minutes, then cool to 20°C for use; the types and amounts of stabilizers mentioned are shown in the table below:

[0075] The quick-fried pearl wrapped skin ingredient formula of table 2 embodiment 1

[0076] ingredients quality% sodium alginate 0.3 gellan gum 0.02 calcium salt 0.2 pure water 99.48 total 100 Soluti...

Embodiment 2

[0088] Preparation of S1 Bead Center Solution:

[0089] After heating the purified water to 50°C, add stabilizer, sweet sugar, chocolate natural ingredients and food flavors, etc., stir at 100rpm for 20 minutes, then cool to 30°C for use, storage time ≤ 15h; The amount added is shown in the table below:

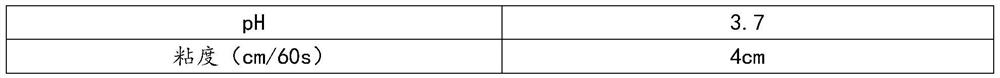

[0090] The composition formula of the quick-fried pearl central liquid of table 4 embodiment 2

[0091] ingredients quality% corn starch 20 White sugar 10 dark chocolate 6 cocoa powder 4 food flavor 6 citric acid 2 pure water 52 total 100 pH 4.2 Viscosity (cm / 60s) 6cm

[0092] The preparation of S2 popping ball wrapped skin: heat up the purified water to 80°C, add the stabilizer, and stir and circulate at 1000rpm for 30 minutes, then cool to 30°C for use; the types and amounts of the stabilizer mentioned are shown in the table below:

[0093] The quick-fried pearl wrapped skin ingredient formula of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com