Organic sulfur sterilization algicide

A sulfur sterilization and algaecide and organic technology, which is applied in the field of organic sulfur sterilization and algaecide, can solve problems such as poor stability and dispersion performance, and achieve the effects of improving sterilization and algaecide performance, improving sterilization and algae killing effect, and optimizing concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

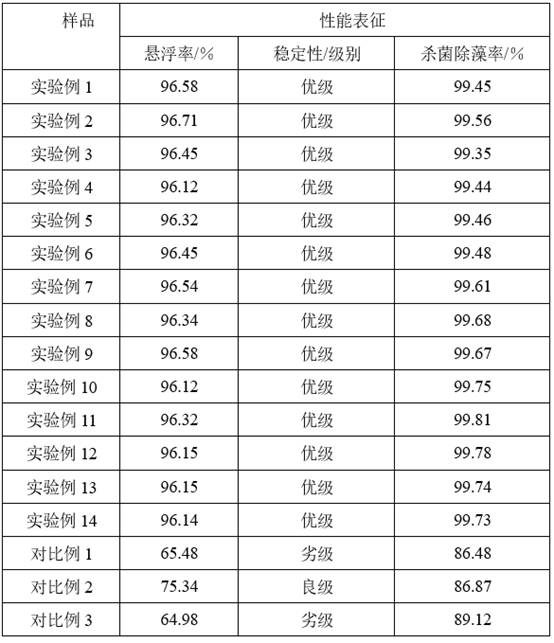

Examples

preparation example 1

[0035] A dithiocyanomethane-coated granule:

[0036] (1) Take 200g of dithiocyanomethane and grind it, sieve to collect dithiocyanomethane with a particle size of 10-15μm and add it to 5kg of deionized water, ultrasonically disperse and collect dithiocyanomethane dispersion slurry;

[0037] (2) Add 1 kg of dithiocyanomethane dispersion slurry to 8 kg of 1mol / L chitosan solution, stir and mix to collect the mixed slurry;

[0038] (3) Add 0.1kg of epichlorohydrin and 0.6kg of formaldehyde to 4kg of mixed slurry at 55°C, stir and mix, adjust the pH to 12 with 0.1mol / L sodium hydroxide solution, and use deionized water after stirring to react Rinse until the washing solution is neutral, and then dry at 60° C. to prepare dithiocyanomethane-coated particles.

preparation example 2

[0040] A dithiocyanomethane-coated granule:

[0041](1) Take 200g of dithiocyanomethane and grind it, sieve to collect dithiocyanomethane with a particle size of 10-15μm and add it to 6.5kg of deionized water, ultrasonically disperse and collect dithiocyano Methane dispersion slurry;

[0042] (2) Add 1kg of dithiocyanomethane dispersion slurry to 9kg of 1mol / L chitosan solution, stir and mix to collect the mixed slurry;

[0043] (3) Add 0.1kg of epichlorohydrin and 0.7kg of formaldehyde to 4.5kg of mixed slurry at 57°C, stir and mix and adjust the pH to 12 with 0.1mol / L sodium hydroxide solution, and use deionized Rinse with water until the washing solution is neutral, and then dry at 60° C. to prepare dithiocyanomethane-coated particles.

preparation example 3

[0045] A dithiocyanomethane-coated granule:

[0046] (1) Take 200g of dithiocyanomethane and grind it, sieve to collect dithiocyanomethane with a particle size of 10-15μm and add it to 8kg of deionized water, ultrasonically disperse and collect dithiocyanomethane dispersion slurry;

[0047] (2) Add 1kg of dithiocyanomethane dispersion slurry to 10kg of 1mol / L chitosan solution, stir and mix to collect the mixed slurry;

[0048] (3) Add 0.1kg of epichlorohydrin and 0.8kg of formaldehyde to 5kg of mixed slurry at 60°C, stir and mix and adjust the pH to 12 with 0.1mol / L sodium hydroxide solution, stir and react with deionized water Rinse until the washing solution is neutral, and then dry at 60° C. to prepare dithiocyanomethane-coated particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com