Structure and manufacturing method of beam-island-membrane integrated resonant pressure sensor

A pressure sensor and resonant technology, applied in the field of micro-electronic mechanical systems, can solve the problems of nonlinear changes of excitation force and detection signal, increase the difficulty of closed-loop control, and be unfavorable for arranging varistors. The effect of detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

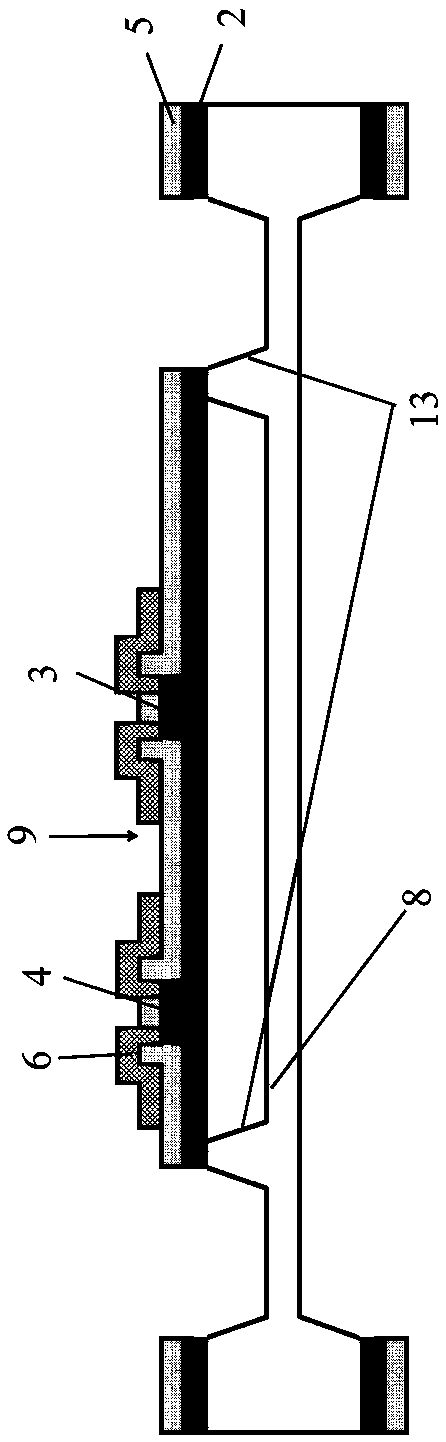

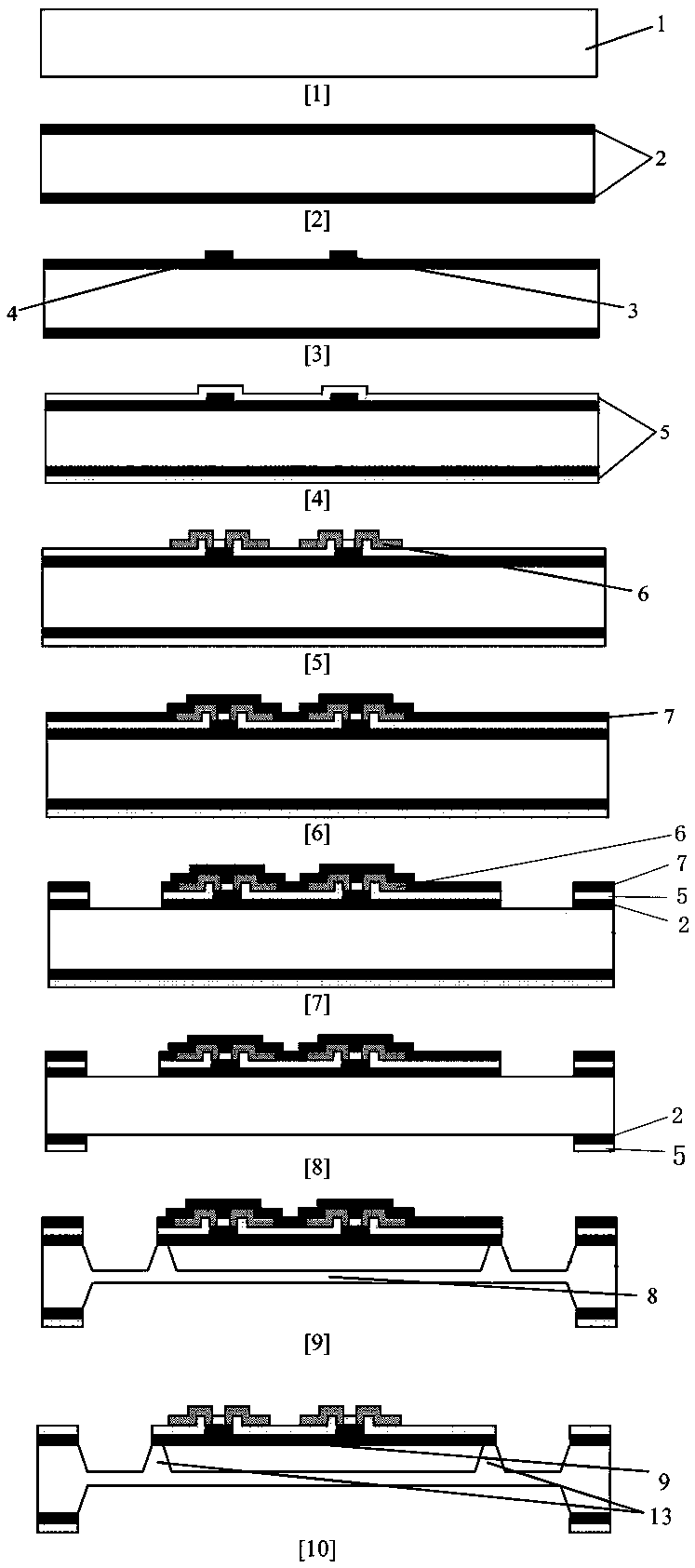

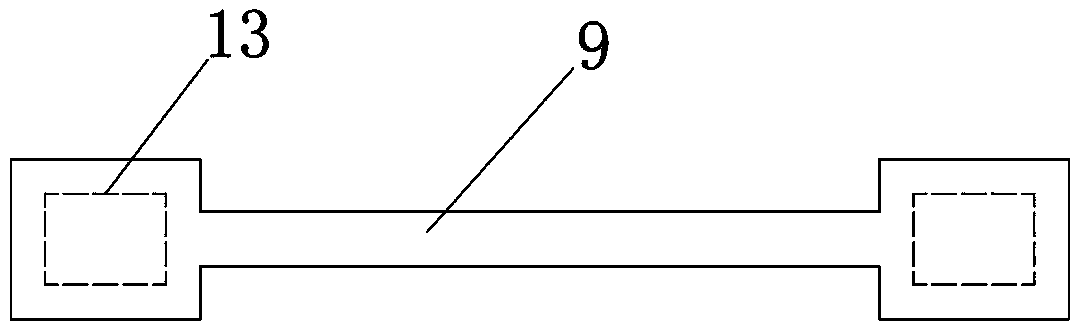

[0060] Embodiment 2: as Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, except that the pressure-sensitive diaphragm 8 and two silicon islands 13 in this embodiment are made of SOI silicon wafer 10 through anisotropic etching solution (potassium hydroxide or tetramethylammonium hydroxide-based etchant), the device layer 103 of the SOI silicon wafer is lightly doped monocrystalline silicon, the resistivity of the substrate layer 101 monocrystalline silicon is less than 0.1Ω.cm, and the doping concentration is less than 70% of the corrosion concentration is stopped.

[0061] In this example, the resonant beam 9 is made of silicon dioxide buried layer 102, device layer 103 monocrystalline silicon and Si 3 N 4 Thin film 5 composition, using Si with tensile stress 3 N 4 The thin film 5 compensates for the compressive stress of the buried silicon dioxide layer 102 .

[0062] The manufacturing process steps of the present embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com