Preparation method of super-hydrophobic fire-resistant hexagonal boron nitride coating

A hexagonal boron nitride, super-hydrophobic technology, applied in the field of refractory coatings, can solve the problems of cracking, cracking, deterioration of the adhesion of refractory coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

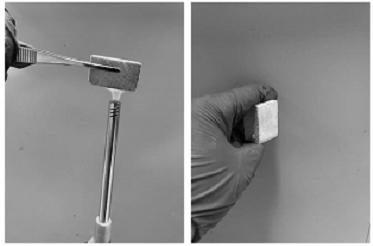

[0022] A preparation method of a superhydrophobic refractory hexagonal boron nitride coating:

[0023] Firstly, air plasma is used to clean the base material, the treatment temperature is 40-60°C, the power is 5KW, the time is 5 minutes, and the treated base is obtained. The base material refers to one of glass, metal, wood, and plastic, and its surface finish is Ra>0.5 μm. It can be used in actual working conditions such as water pumps and building timber.

[0024] Then, according to the mass fraction, mix 2.5~3% of binder, 3.5~5% of hexagonal boron nitride fluoride, 0.05~0.5% of barium stearate, 70~78% of deionized water, and 15~20% of acetone, After ultrasonic stirring for more than 3 hours, the spray slurry can be obtained. Among them: binder refers to mixing trisodium phosphate, aluminum hydroxide and deionized water at a mass fraction ratio of 1:1:5~5:3:20, heating the oil bath to 85 ℃ for reaction, and continuously stirring for 3 hours be made of. Fluorinated hexago...

Embodiment 1

[0026] Example 1 A method for preparing a superhydrophobic refractory hexagonal boron nitride coating:

[0027] (1) Plasma pretreatment: Plasma pretreatment is performed on the wood surface to make the surface have a certain degree of cleanliness and roughness, and to increase the adhesion between the substrate and the coating. Its pretreatment power is 5 KW, the time is 5 minutes, and the air source is air.

[0028] (2) Preparation of binder: Mix 20 g of trisodium phosphate and 20 g of aluminum hydroxide in 100 mL of aqueous solution and react at 75°C, stirring continuously for 3 hours.

[0029] (3) Preparation of fluorinated hexagonal boron nitride: gradually add 1.5 g of perfluorodecyltriethoxysilane into 50 mL of hexagonal boron nitride in acetone solution, in which the content of hexagonal boron nitride is 5 g, and continuously stir for 24 hours.

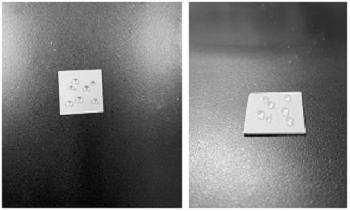

[0030] (4) Spraying slurry preparation: 3.5 g of binder, 5 g of hexagonal boron nitride fluoride, 0.2 g of dispersant, 100 g...

Embodiment 2

[0032] Example 2 A method for preparing a superhydrophobic refractory hexagonal boron nitride coating:

[0033] ⑴Plasma pretreatment: Plasma pretreatment is performed on the cast iron surface to make the surface have a certain degree of cleanliness and roughness, and to increase the adhesion between the substrate and the coating. Its pretreatment power is 5KW, the time is 5 minutes, and the air source is air.

[0034] (2) Preparation of binder: Mix 25 g of trisodium phosphate and 15 g of aluminum hydroxide in 100 mL of aqueous solution and react at 75°C, stirring continuously for 3 hours.

[0035] (3) Preparation of hexagonal boron nitride fluoride: gradually add 2 g of perfluorodecyltriethoxysilane into 50 mL of hexagonal boron nitride in acetone solution, in which the content of hexagonal boron nitride is 5 g, and stir continuously for 24 hours.

[0036] (4) Spraying slurry preparation: 4 g of binder, 5.5 g of hexagonal boron nitride fluoride, 0.5 g of dispersant, 100 g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com