Agricultural machinery type ecological method straw fibrosis technology and equipment

An agricultural machinery type and agricultural mechanization technology, applied in the field of straw solid waste disposal and recycling, can solve the problems of stagnant chemical and chemical industrial practice, no commercial value, low utilization rate of straw, etc. High cost, small investment, quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

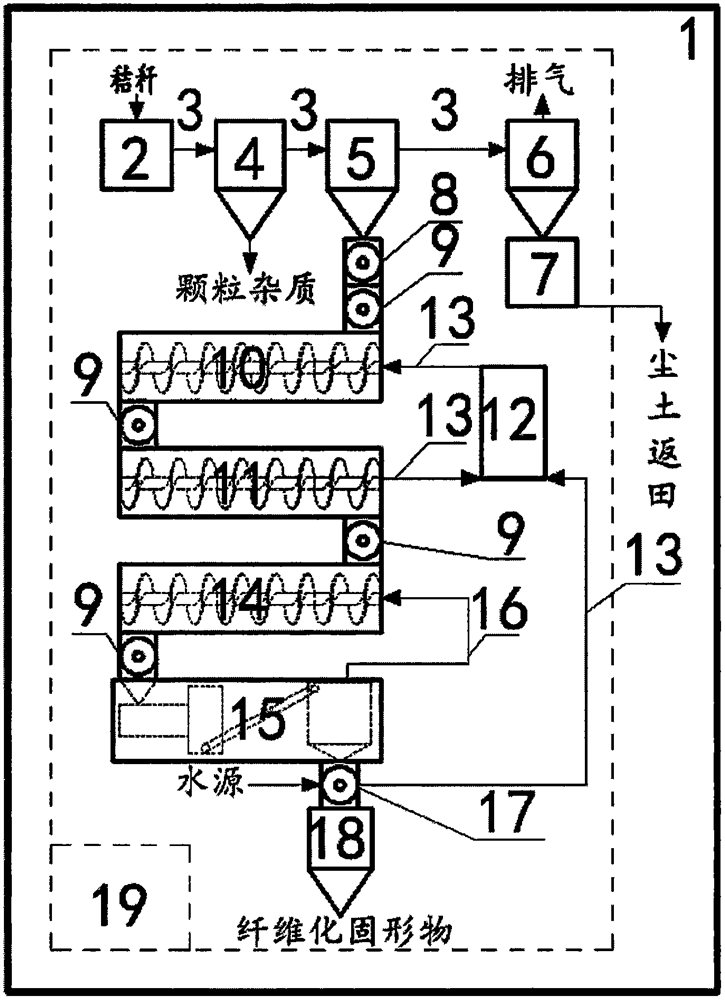

[0022] like figure 1 As shown, the agricultural machinery type ecological straw fiberization technology and equipment of the present invention include an agricultural mechanization steel carrier 1, a shredder 2, an air duct 3, a particle dust collector 4, a raw material storage container 5, and a bag dust collector 6 , agricultural mechanization duster 7, measuring device 8, tubular screw conveyor 9, raw material prepreg machine 10, raw material solid-liquid adjustment and homogenization compressor unit 11, water-liquid collection and treatment unit 12, catheter tube 13, cooking softener And heat supply unit 14, thermal grinding separation unit 15, steam pipe 16, heat exchange unloader 17, finished product storage bin 18, transformer power and control cabinet 19.

[0023]The agricultural machinery type thermodynamic straw fibrillation technology and equipment of the present invention firstly designs and manufactures the agricultural mechanized steel carrier 1 as a square steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com