Iron nitride nano-powder and preparation method thereof

A technology of nano-powder and iron nitride, which is applied in the direction of chemical instruments and methods, nanotechnology, nitrogen compounds, etc., can solve the problems of complex process and low purity of iron nitride nano-powder, and achieve simple process and improved Agglomeration of product particles and the effect of preventing self-sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

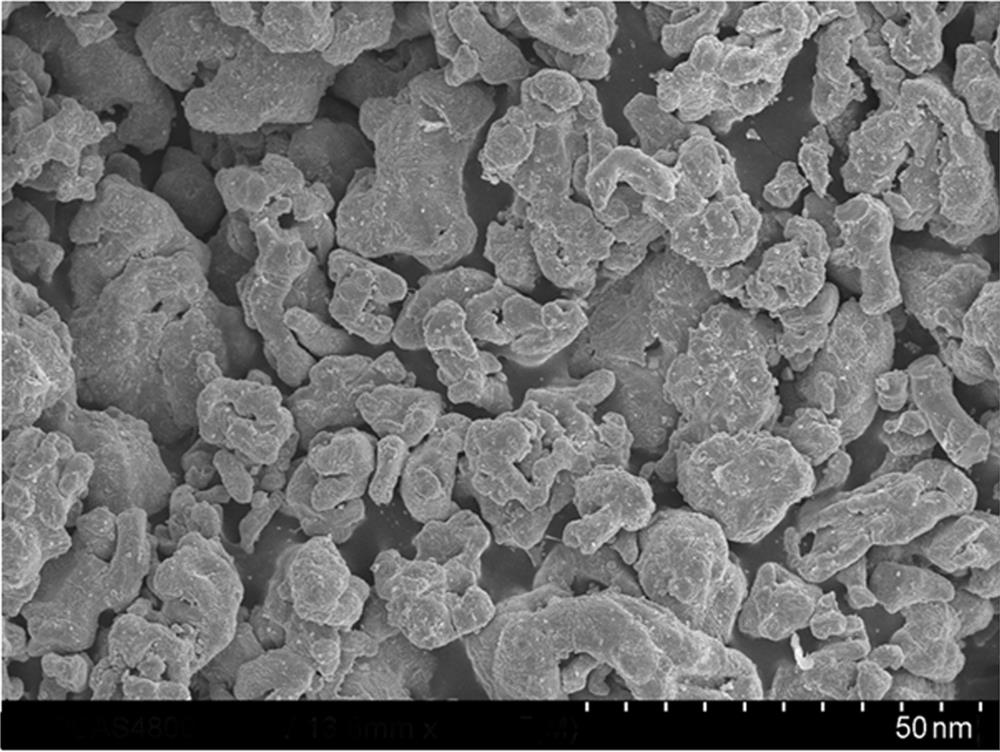

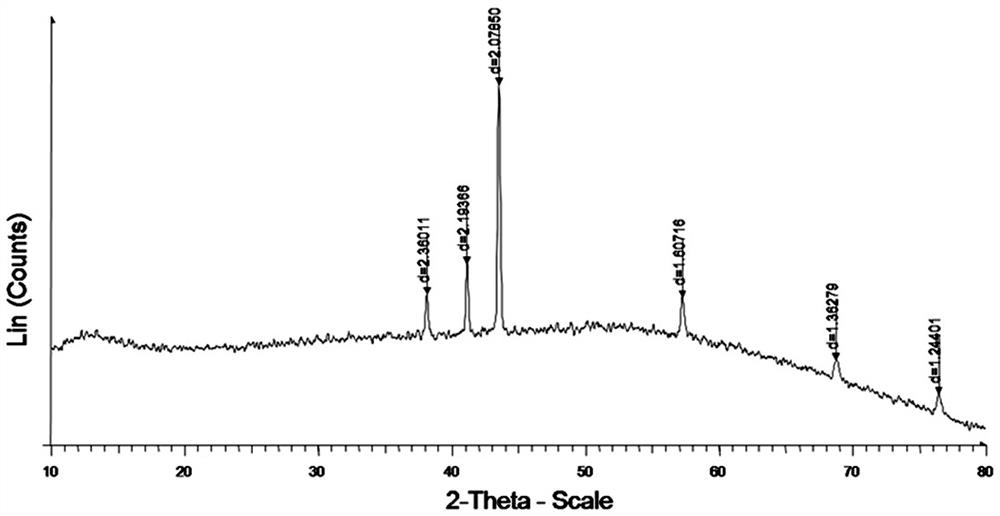

[0023] Weigh 50g of metal Fe powder with a purity of 99.99wt% and a particle size of 50nm in a glove box, and then weigh 10g of a reaction additive NH with a purity of 99.9%. 4 F powder (additive A), after fully mixing for 20 minutes, spread it in a molybdenum crucible. Put the mixed materials into the quartz sintering furnace, vacuumize to 20KPa, feed nitrogen-hydrogen mixed gas with a volume ratio of 1:1, control the flow rate at 1.5L / min, and then raise the temperature to 350°C at a rate of 5°C / min , then turn off N 2 , into NH 3 , H 2 and NH 3 The volume ratio is 1:3, and the temperature is raised to 550°C at a rate of 2°C / min, and kept for 3h, then turn off the NH 3 and H 2 , into N 2 The temperature was lowered to 200°C at a rate of 5°C / min, and then naturally cooled to room temperature to obtain a sintered product, which was pulverized and classified to obtain iron nitride below 100nm, which was characterized as follows: figure 1 and figure 2 shown.

[0024] R...

Embodiment 11-15

[0032] With reference to the preparation method of Example 1, the particle size of the raw iron powder was changed, and other process conditions were the same as in Example 1. The N content and particle morphology of the obtained iron nitride powder were tested, and the obtained results are shown in Table 2. shown.

[0033] Table 2

[0034]

[0035] It can be seen from Table 2 that the particle size of the raw material iron powder directly affects the particle size of the product, and the product particle size can be adjusted by changing the particle size of the raw material as required.

Embodiment 16-29

[0037] With reference to the preparation method of embodiment 1, change sintering temperature, H 2 and NH 3 The volume ratio and other process conditions are the same as in Example 1. The N content and particle morphology of the obtained iron nitride powder were tested, and the results are shown in Table 3.

[0038] table 3

[0039]

[0040]

[0041] It can be seen from Table 3 that by changing the sintering temperature and H 2 and NH 3It can be seen from the volume ratio that as the sintering temperature increases, the nitrogen content first increases and then decreases, and the particles agglomerate and the particle size becomes larger; when the sintering temperature is 550°C and the holding time is 3h, H 2 and NH 3 The volume ratio is 1:3, the particle uniformity is the best, the agglomeration is less, and the dispersion is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com