Carbon nanotube modified lead dioxide electrode and preparation method and application thereof

A technology of carbon nanotube modification and lead dioxide, applied in the field of electrochemistry, can solve the problems of undegraded medical wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036]According to another aspect of the present invention, there is also provided a method of preparing a carbon nanotube modified neutral electrode, the preparation method comprising the steps of:

[0037]Matrix pretreatment;

[0038]A metal oxide underlayer is prepared on the surface of the substrate;

[0039]Provide carbon nanotubes;

[0040]The carbon nanotubes are doped into the lead source, and the electrodeposition is modified to beta-Pbo2Further, the carbon nanotubes modified a lead electrode.

[0041]The pretreatment of the present invention preferably includes: placing the substrate into a solution containing a ketone and a base, is ultrasonic, and then etching, cleaning in an acid solution under high temperature conditions, and is stored in an acid storage liquid. The present invention performs pretreatment of the substrate, and can have an increase in the amount of electrodeposition area to increase the bonding force of the substrate and the active layer.

[0042]In the present invention...

Embodiment 1

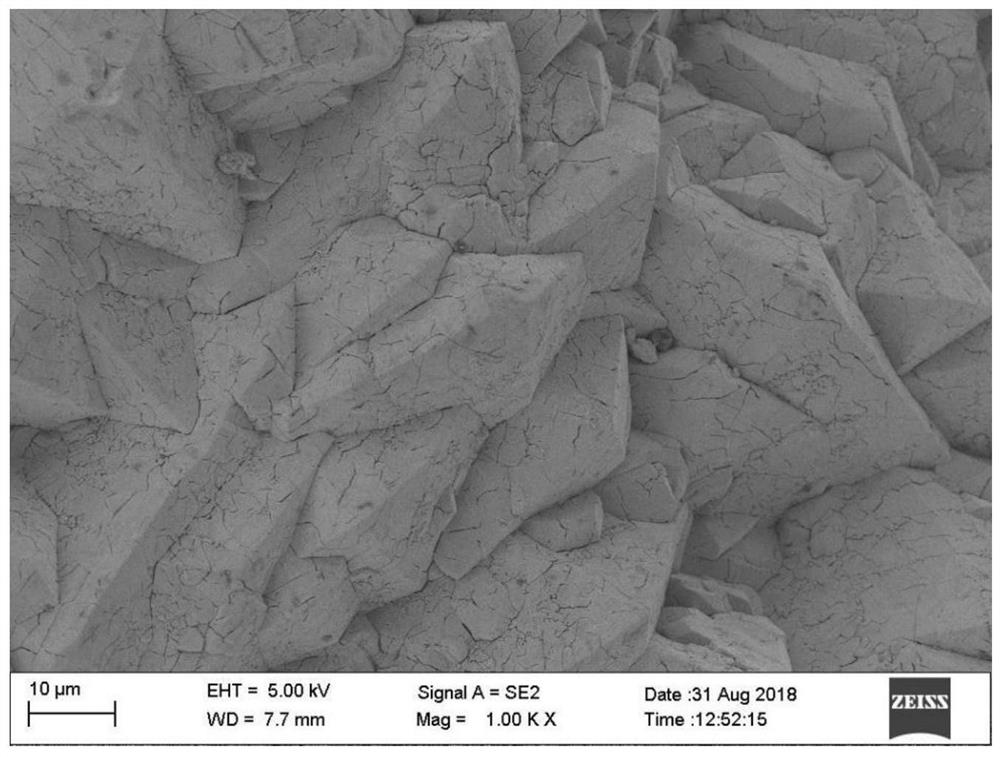

[0105](1) Preparation of nickel matrix, polished the tied nickel base (2cm * 5cm), sequentially polished, wash it with deionized water; put the polished nickel net into acetone and 0.8mol·L-1Ultrasound treatment in NaOH (V / V = 1: 3) for 30 min, and then placed in deionized water for 30 min; then placed the nickel base at 15% (mass fraction) oxalic acid etching liquid etching 1h, then use A large amount of deionized water cleaned the nickel base after etching, and then preserved in the oxalic acid preservation fluid of 1.0% (mass fraction).

[0106](II) Preparation of the bottom layer of the tin oxide, 15 g tin tin and 1 g of trichloride (mass ratio 15: 1) is dissolved in 1.5 g of concentration hydrochloric acid (concentration of 37 wt%) and 70 g of isopropyl alcohol mixing solution The coating liquid was formed, and the coating liquid was evenly applied to the surface of the treated nickel base, dried at 120 ° C for 20 min at 120 ° C, and then placed at 600 ° C for 20 min at 600 ° ...

Embodiment 2

[0111](1) Pretreatment of titanium-based body, polished the treated titanium base (2cm * 5cm), sequentially polished, washed with deionized water; put the polished titanium net into acetone and 0.8mol·L-1Ultrasound treatment in NaOH (V / V = 1: 3) for 30 min, and then placed in deionized water for 30 min; then placed the titanium base in 15% (mass fraction) oxalic acid etching fluid etching 1h, then use A large amount of deionized water cleaned the titanium base after etching, and then preserved in an oxalic acid preservation liquid in a 1.0% (mass fraction).

[0112](2) Preparation of the bottom layer of the ruthenium oxide, 15 g of tetrachloride and 1 g of trichloride (mass ratio 15: 1) were dissolved in 1.5 g of concentration hydrochloric acid (concentration of 37 wt%) and 70 g of isopropyl alcohol mixed solution. The coating liquid was made, and the coating liquid was evenly coated onto the surface of the treated titanium-based body, dried at 120 ° C for 20 min in the oven, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com