Wood wax oil resin and preparation method thereof and composition containing wood wax oil resin

A wood wax oil and resin technology, applied in the field of coatings, can solve the problems of not meeting the technical requirements of wood wax oil, the resin is opaque, the grafting rate is low, etc., and achieves yellowing resistance performance without fading for a long time, good wettability and gloss. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

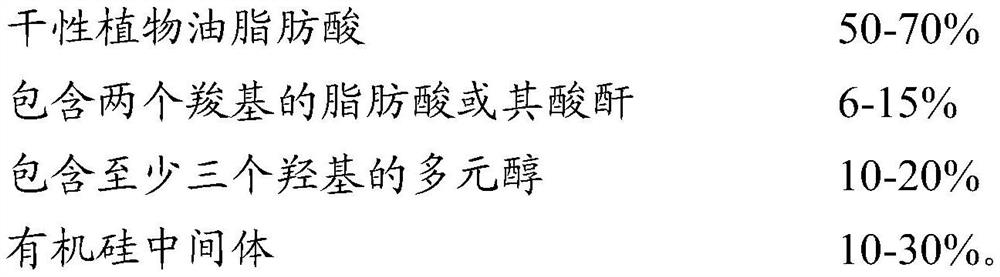

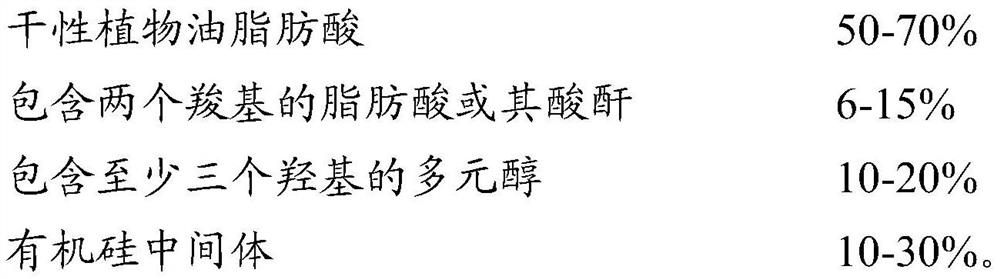

Method used

Image

Examples

Embodiment 1

[0053] Weigh 96g of phenyltriethoxysilane, 60g of dimethyldimethoxysilane, and 18g of methyltriethoxysilane, mix them, add 50g of water, 150g of toluene and 0.4g of trifluoromethanesulfonic acid under stirring conditions and heat at 55°C React for 8 hours, add 50g of water and stir, take the upper organic layer, wash with deionized water until neutral, heat the organic layer to 130°C while vacuuming on a rotary evaporator, vacuumize at 130°C for 2h and remove toluene, drop To room temperature to obtain an organosilicon intermediate, the phenyl content of the organosilicon intermediate is 63.4%;

[0054] The number average molecular weight of the test organosilicon intermediate is 1420, the number average molecular weight is determined by gel permeation chromatography, the instrument model is SW-105, the mobile phase used is tetrahydrofuran, the standard sample is polystyrene, and the sample concentration is 10mg / ml. Basic parameter setting: column oven temperature: 40°C; pump ...

Embodiment 2

[0056] Weigh 48g of phenyltriethoxysilane, 90g of dimethyldimethoxysilane, and 36g of methyltriethoxysilane and mix them, add 60g of water, 180g of toluene and 0.6g of trifluoromethanesulfonic acid under stirring conditions and heat to 70 React at ℃ for 5 hours, add 50g of water and stir, take the upper organic layer, wash with deionized water until neutral, heat the organic layer to 120℃ while vacuuming on a rotary evaporator, vacuum at 120℃ for 2h and remove toluene , down to room temperature to obtain an organosilicon intermediate, the phenyl content of the organosilicon intermediate is 32.5%;

[0057] The number average molecular weight of the test organosilicon intermediate is 1020, the number average molecular weight is determined by gel permeation chromatography, the instrument model is SW-105, the mobile phase used is tetrahydrofuran, the standard sample is polystyrene, and the sample concentration is 10mg / ml. Basic parameter setting: column oven temperature: 40°C; pum...

Embodiment 3

[0059] Weigh 24g of phenyltriethoxysilane, 45g of dimethyldimethoxysilane, 54g of methylphenyldimethoxysilane and 36g of methyltriethoxysilane and mix them, add 80g of water and 200g of toluene under stirring conditions Heat 1.0g of trifluoromethanesulfonic acid to 65°C to react for 3 hours, add 50g of water to stir, wash with deionized water until neutral, heat the organic layer to 120°C while vacuuming on a rotary evaporator, and then Vacuumize for 2 hours and remove toluene, lower to room temperature to obtain an organosilicon intermediate, the phenyl content of the organosilicon intermediate is 57.5%;

[0060] The number average molecular weight of the test organosilicon intermediate is 820, and the number average molecular weight is determined by gel permeation chromatography, the instrument model is SW-105, the mobile phase used is tetrahydrofuran, the standard sample is polystyrene, and the sample concentration is 10mg / ml. Basic parameter setting: column oven temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap