Lightweight anti-fatigue PEBA sole and forming process thereof

An anti-fatigue, lightweight technology, applied in the direction of soles, footwear, applications, etc., can solve the problem of reducing the agility of athletes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

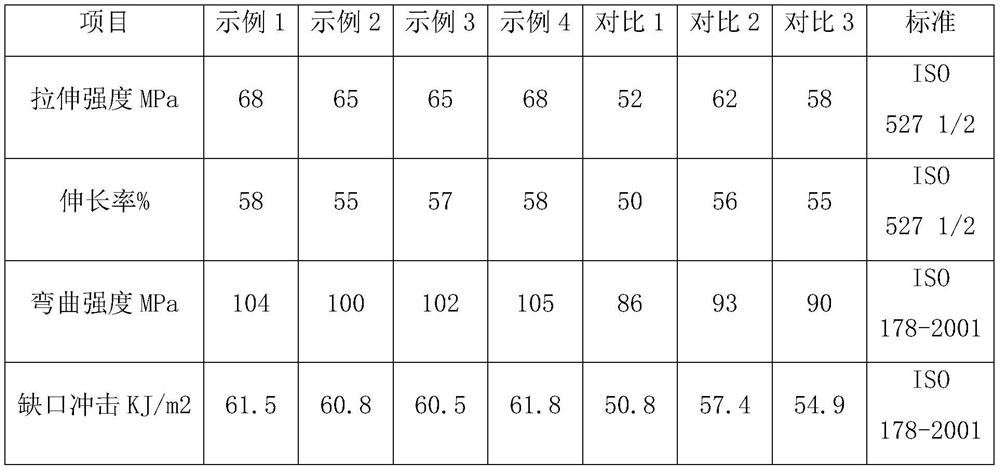

Examples

Embodiment 1

[0023] The present embodiment provides a kind of lightweight anti-fatigue PEBA sole, is made up of following parts by weight: 85 parts of PEBA material rice, 15 parts of modified PEBA particles, 1 part of talcum powder, 1.5 parts of zinc stearate, 6 parts of anti-wear agent, 0.3 part of anti-ultraviolet light absorbing agent, and 0.4 part of antioxidant, wherein: said anti-wear agent is a polymer polysiloxane with an average molecular weight of 4000-10000, and said anti-ultraviolet light absorption The agent is an ultraviolet light absorber UV320, and the antioxidant is an antioxidant A30. Its molding process specifically includes the following steps: S1, preparing modified PEBA particles; S2, using the modified PEBA particles, talcum powder, zinc stearate, wear-resistant agent, anti-ultraviolet light absorbing agent, and antioxidant in step S1 according to the formula Add it into a twin-screw extruder, blend and extrude, and pelletize to obtain mixed pellets; S3, inject the m...

Embodiment 2

[0027] The present embodiment provides a kind of lightweight anti-fatigue PEBA shoe sole, is made up of the following parts by weight: 80 parts of PEBA material rice, 10 parts of modified PEBA particles, 0.5 part of talcum powder, 1 part of zinc stearate, 3 parts of anti-wear agent, 0.5 part of antioxidant and 0.5 part of color masterbatch, wherein: the anti-wear agent is maleic anhydride grafted ultra-high molecular weight polyethylene with a molecular weight of 2 million to 3.5 million, and the anti- The oxidizing agent is antioxidant H10. Its molding process specifically includes the following steps: S1, preparing modified PEBA particles; S2, adding the modified PEBA particles, talcum powder, zinc stearate, wear-resistant agent, antioxidant and color masterbatch in step S1 to double In the screw extruder, blend and extrude, and pelletize to obtain mixed pellets; S3, inject the mixed pellets prepared in step S2 into the shoe sole mold for injection molding, the pressure is 7...

Embodiment 3

[0031] The present embodiment provides a kind of lightweight anti-fatigue PEBA shoe sole, is made up of the following parts by weight: 100 parts of PEBA material rice, 20 parts of modified PEBA particles, 1.5 parts of talcum powder, 1 part of zinc stearate, 10 parts of anti-wear agent, 0.6 part of anti-ultraviolet light absorbing agent, 0.2 part of antioxidant and 1.5 parts of color masterbatch, wherein: the anti-wear agent is a polymer polysiloxane with an average molecular weight of 4000-10000 , the anti-ultraviolet light absorber is ultraviolet light absorber UV380, and the antioxidant is antioxidant A30 and antioxidant H10. The molding process specifically includes the following steps: S1, preparing modified PEBA particles; S2, mixing the modified PEBA particles, talcum powder, zinc stearate, wear-resistant agent, anti-ultraviolet light absorbing agent, antioxidant and color The masterbatch is added to the twin-screw extruder according to the formula, blended and extruded,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com