High-reflection glass slurry for photovoltaic module glass backboard and preparation method thereof

A glass paste, glass backplane technology, applied in reflective/signal coatings, photovoltaic power generation, electrical components, etc., can solve problems such as low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

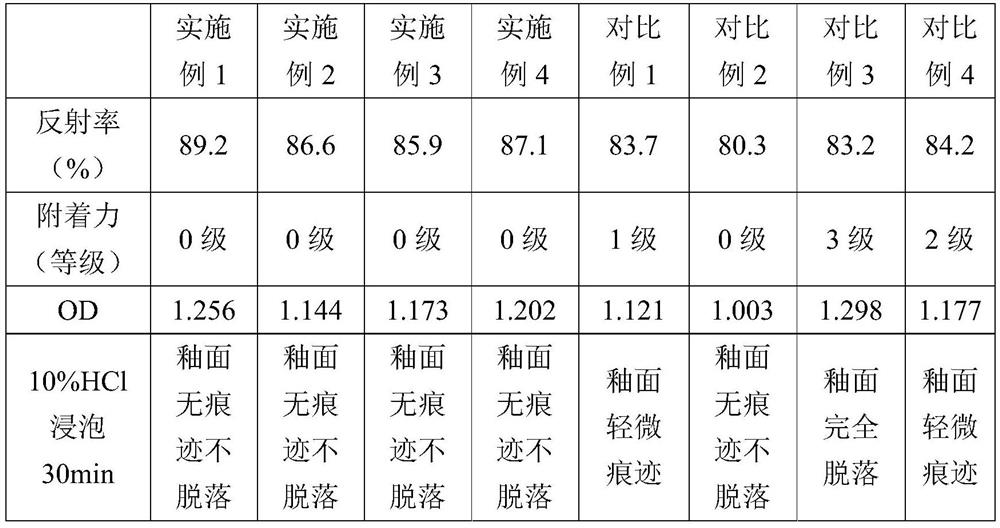

Embodiment 1~4 and comparative example 1~3

[0030] Embodiment 1~4 and comparative example 1~3 preparation process

[0031] (1) Preparation of glass powder: Mix the raw materials of the low-melting point glass powder in the formula quantity evenly to obtain the base material; heat the base material and fire it for 30 minutes, and after the melt is homogenized and clarified, a uniform glass liquid is formed; the glass Pour the solution into deionized water and quench to obtain cullets; add water to the cullets and wet grind them for 3 hours, dry them, and pass them through a 250-mesh sieve to obtain low-melting-point glass powders.

[0032] (2) Preparation of mixed powder: Take the low-melting-point glass powder and titanium dioxide in the step (1) according to the proportioning ratio, and after mixing evenly, heat the uniformly mixed titanium dioxide and low-melting-point glass powder and keep them warm for a period of time, and cool naturally After reaching room temperature, pass through a 250-mesh sieve to obtain a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com