Photochromic coating and preparation method thereof

A photochromic and coating technology, applied in the coating field, can solve problems such as the inability to meet more needs of people, and achieve the effects of fast curing speed, good hardness and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

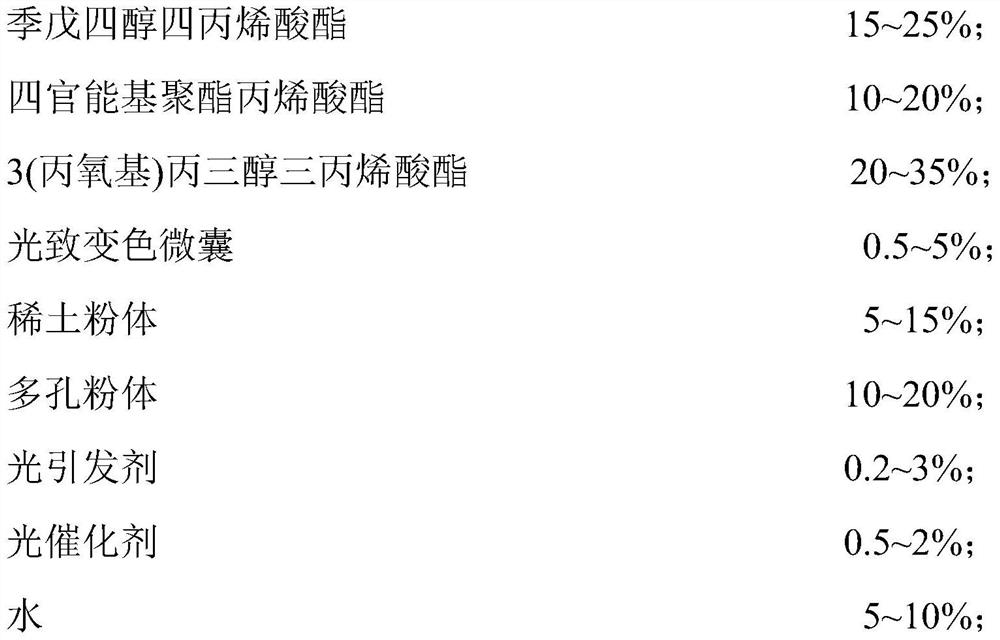

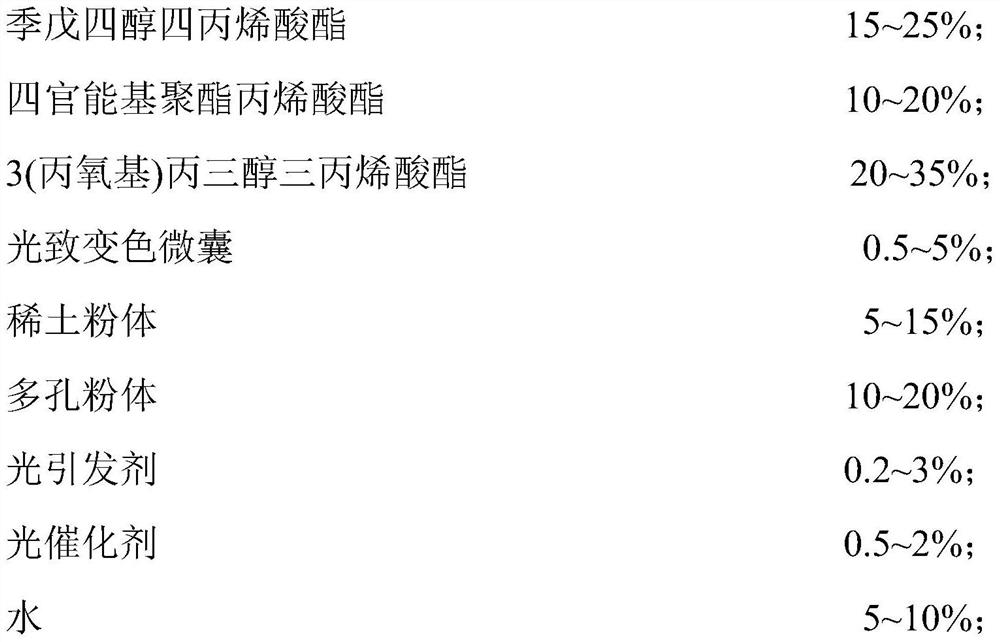

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of photochromic microcapsules is not particularly limited, and may be interfacial polymerization method, in-situ polymerization method based on melamine-formalin, etc., curing coating method in liquid, phase separation method from aqueous solution, or organic solvent Phase separation method, soluble dispersion cooling method, air suspension coating method, spray drying method, etc. The photochromic microcapsule used in the present invention is the photosensitive microcapsule disclosed in the patent whose publication number is CN109876743A.

[0035] The rare earth powder is at least one of yttrium phosphate, lanthanum phosphate and cerium phosphate. The particle size of the rare earth powder is preferably between 1 and 10 μm, and if it exceeds this particle size range, its dispersibility and stability in the photochromic paint will be affected.

[0036] Rare earths have abundant electronic energy levels. Under the irradiation of ultraviolet and vi...

Embodiment 1

[0048] Take by weighing 20 parts by weight of pentaerythritol tetraacrylate, 15 parts by weight of tetrafunctional polyester acrylate (Guangzhou Handong Trading Co., Ltd., 6325-100), 30 parts by weight of 3 (propoxyl) glycerol triacrylate, light 2.5 parts by weight of chromogenic microcapsules, 10 parts by weight of rare earth powder (yttrium phosphate particles with a particle size of 3-8 μm), porous powder (silicon dioxide particles with a particle size of 3-8 μm, wherein the microporous powder and the medium The mass ratio of hole powder is 1.2:1) 15 weight parts, photoinitiator (benzil dimethyl ketal) 0.5 weight part, photocatalyst (nano TiO 2 ) 1 part by weight and 6 parts by weight of water.

[0049] Mix the rare earth powder and the photocatalyst evenly, then add them into pentaerythritol tetraacrylate, mix and stir evenly, and obtain the mixture A. Add the photochromic microcapsules into the four-functional polyester acrylate, mix and stir evenly, and obtain mixture B...

Embodiment 2

[0052] Take by weighing 15 parts by weight of pentaerythritol tetraacrylate, 15 parts by weight of tetrafunctional polyester acrylate (Meiyuan Special Chemical Co., Ltd., Miramer PS1000), 35 parts by weight of 3 (propoxyl) glycerol triacrylate, photoinduced 2.5 parts by weight of color-changing microcapsules, 5 parts by weight of rare earth powder (lanthanum phosphate particles with a particle size of 3 to 8 μm), porous powder (silicon dioxide particles with a particle size of 3 to 8 μm, wherein the microporous powder and mesoporous The mass ratio of the powder is 1.2:1) 20 parts by weight, 0.5 parts by weight of photoinitiator (benzil dimethyl ketal), 1 part by weight of photocatalyst (nano-ZnO) and 6 parts by weight of water.

[0053] Mix the rare earth powder and the photocatalyst evenly, then add them into pentaerythritol tetraacrylate, mix and stir evenly, and obtain the mixture A. Add the photochromic microcapsules into the four-functional polyester acrylate, mix and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com