Steel wire mesh skeleton plastic composite pipe and preparation method thereof

A steel mesh and composite pipe technology, applied in the field of composite pipes, can solve the problems of low peeling strength of composite pipes, failure to solve the problem of steel-plastic interface and delamination at the joint of composite pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

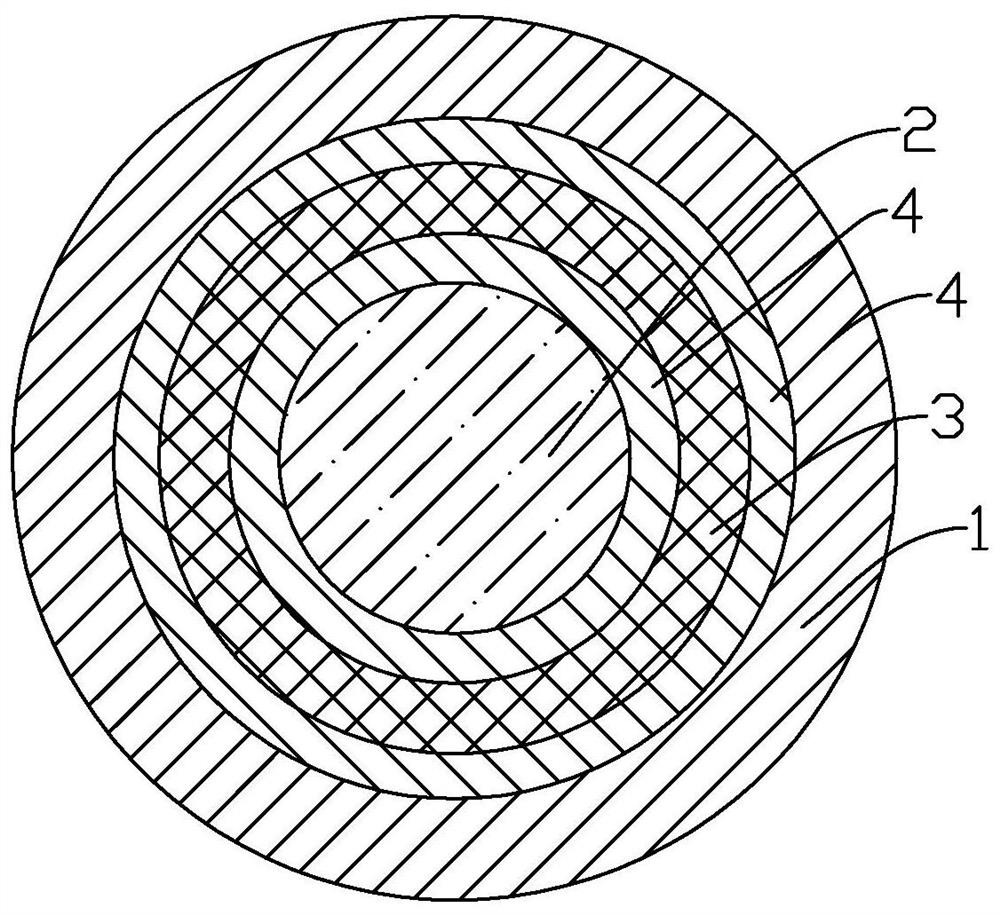

[0043] A steel wire mesh skeleton plastic composite pipe, such as figure 1 As shown, it includes an outer layer polyethylene pipe 1, an inner layer polyethylene pipe 2 and a steel wire mesh 3 arranged between the outer layer polyethylene pipe 1 and the inner layer polyethylene pipe 2, and the outer layer polyethylene pipe 1 and the steel wire mesh 3 The connection between the inner layer polyethylene pipe 2 and the steel wire mesh 3 is through the bonding layer 4;

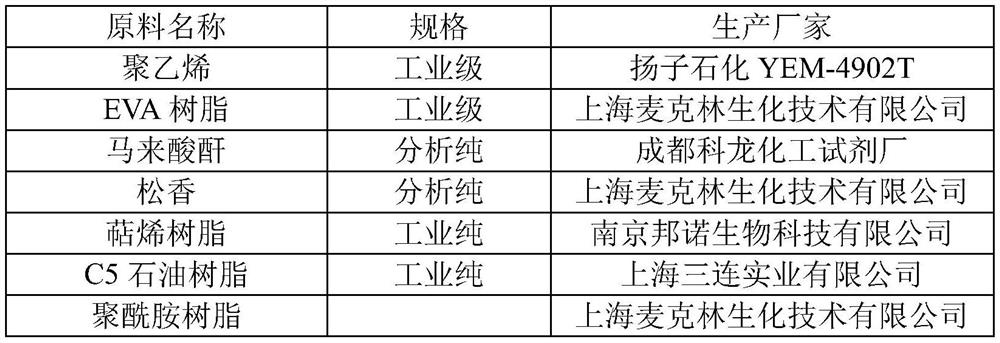

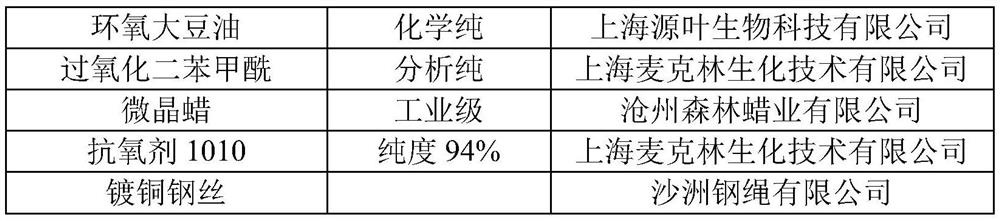

[0044] Wherein the adhesive layer 4 is made of adhesive, each raw material of adhesive is as shown in table 2

[0045] Each raw material and quality of binder in table 2 embodiment 1

[0046] raw material mass (kg) raw material mass (kg) polyethylene 50 Ground calcium carbonate 5 maleic anhydride 15 Epoxidized soybean oil 2 Dibenzoyl peroxide 3 rosin 2 EVA resin 25 Antioxidant 1010 2 Microcrystalline Wax 10 Titanium dioxide 4

[0047] The preparatio...

Embodiment 2

[0057] A steel wire mesh skeleton plastic composite pipe, such as figure 1 As shown, it includes an outer layer polyethylene pipe 1, an inner layer polyethylene pipe 2 and a steel wire mesh 3 arranged between the outer layer polyethylene pipe 1 and the inner layer polyethylene pipe 2, and the outer layer polyethylene pipe 1 and the steel wire mesh 3 The connection between the inner layer polyethylene pipe 2 and the steel wire mesh 3 is through the bonding layer 4;

[0058] Wherein the bonding layer 4 is made of bonding agent, and each raw material of bonding agent is the same as embodiment 1.

[0059] A method for preparing a steel mesh skeleton plastic composite pipe, specifically comprising the following steps:

[0060] S1. Put the dried polyethylene into the injection molding machine to melt and extrude. The temperature of the barrel of the injection molding machine is 130°C, the temperature of the head is 140°C, and the temperature of the die is 150°C to obtain the inner ...

Embodiment 3

[0067] A steel wire mesh skeleton plastic composite pipe, such as figure 1 As shown, it includes an outer layer polyethylene pipe 1, an inner layer polyethylene pipe 2 and a steel wire mesh 3 arranged between the outer layer polyethylene pipe 1 and the inner layer polyethylene pipe 2, and the outer layer polyethylene pipe 1 and the steel wire mesh 3 The connection between the inner layer polyethylene pipe 2 and the steel wire mesh 3 is through the bonding layer 4;

[0068] Wherein the adhesive layer 4 is made of adhesive, each raw material of adhesive is as shown in table 3

[0069] Each raw material and quality of binder in table 3 embodiment 3

[0070] raw material mass (kg) raw material mass (kg) polyethylene 55 Epoxidized soybean oil 4 maleic anhydride 10 Terpene resin 3 Dibenzoyl peroxide 4 Antioxidant 1010 3 EVA resin 20 Titanium dioxide 5 Microcrystalline Wax 15 polyamide resin 5 Ground calcium carbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com