Online hot plate furnace hazardous waste co-processing device and using method

A technology for hazardous waste and co-processing, which is applied in the steam generation method, combustion method and steam engine device using heat carrier, which can solve the problems of insufficient work quality and work efficiency, uneven distribution of pulverized coal, and uneven heat release, etc. Achieve the effect of improving work quality and work efficiency, improving combustion quality, and complete combustion of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

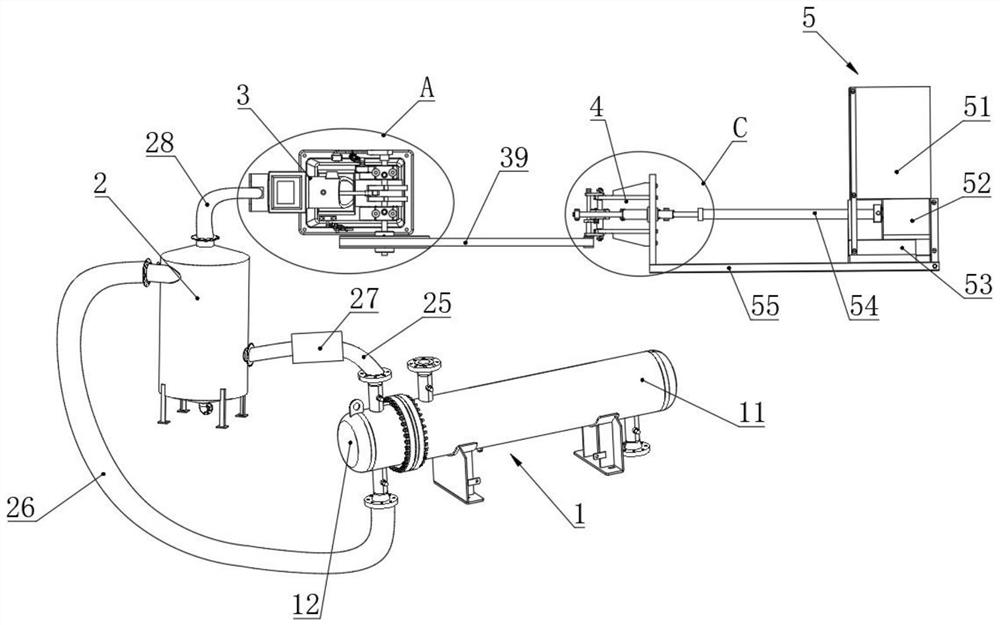

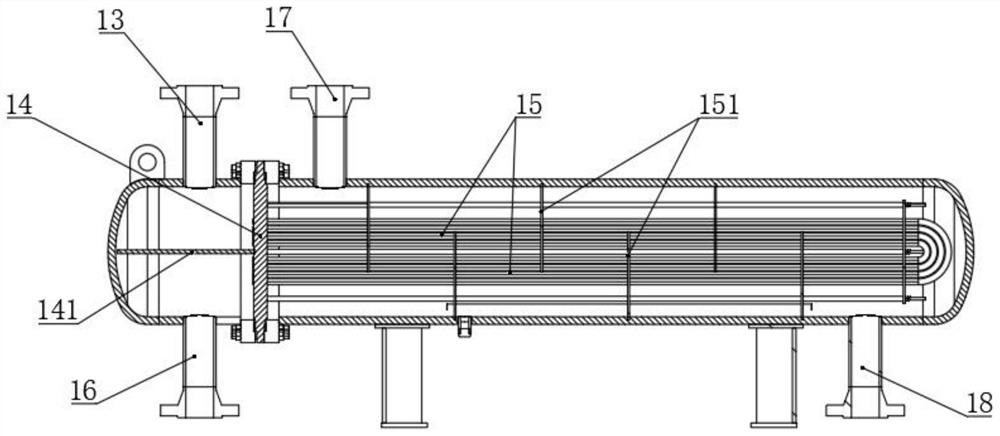

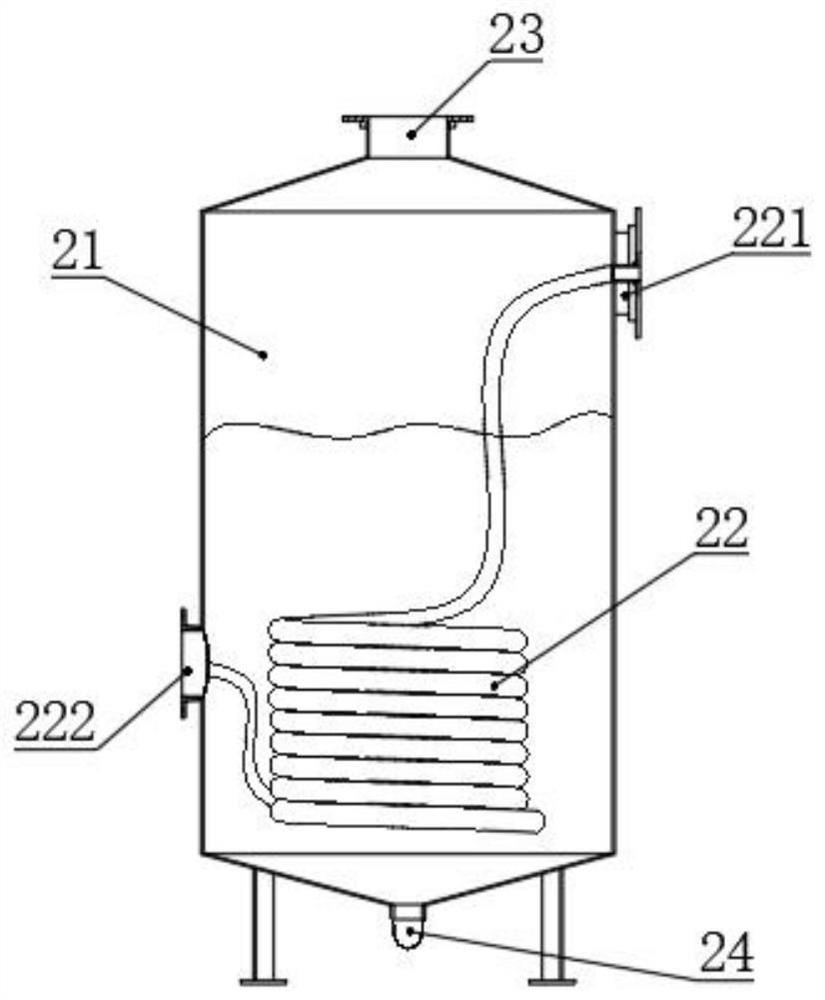

[0070] Such as Figure 1-10 As shown, the on-line hot plate furnace co-processing hazardous waste device includes a heat exchange device 1, one end of the heat exchange device 1 is connected to the hot plate furnace, the other end is connected to the decomposition furnace, and it also includes a steam generating unit 2 and a steam engine 3 , a power conversion unit 4 and an abrasive unit 5, the inside of the heat exchange device 1 is provided with a closed circulation pipeline, the inside of the circulation pipeline is filled with liquid, and the outside of the circulation pipeline is connected to the steam generation unit 2, and the steam generation The unit 2 is connected with the steam engine 3, and the output end of the steam engine 3 is connected with the abrasive unit 5 through the power conversion unit 4, and the pulverized coal is housed in the abrasive unit 5, and the pulverized coal processed by the abrasive unit 5 One part is sent into the hot plate furnace, and the...

Embodiment 2

[0087] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, the on-line hot plate furnace co-processing hazardous waste device includes a heat exchange device 1, one end of the heat exchange device 1 is connected to the hot plate furnace, the other end is connected to the decomposition furnace, and it also includes a steam generating unit 2 and a steam engine 3 , a power conversion unit 4 and an abrasive unit 5, the inside of the heat exchange device 1 is provided with a closed circulation pipeline, the inside of the circulation pipeline is filled with liquid, and the outside of the circulation pipeline is connected to the steam generation unit 2, and the steam generation The unit 2 is connected with the steam engine 3, and the output end of the steam engine 3 is connected with the abrasive unit 5 through the power conversion unit 4, and the pulverized coal is housed in the abrasive unit 5, and the pulverized coal processed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com