High-voltage composite spinel-coated positive electrode material and preparation method thereof

A cathode material, spinel technology, applied in the field of high-voltage composite spinel-coated cathode materials and its preparation, can solve the problems of low discharge capacity, poor cycle performance, instability, etc., to reduce side reactions, Significant redox activity, reducing corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

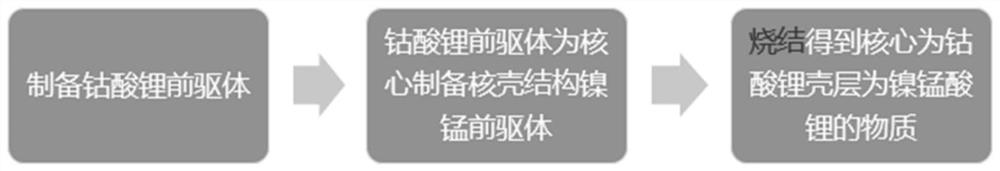

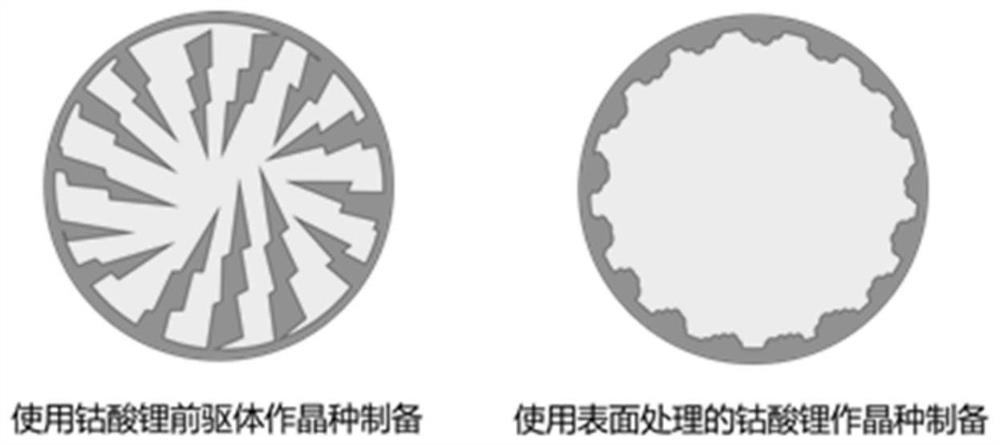

Method used

Image

Examples

Embodiment 1

[0063] The positive electrode material provided in this example is Li with a core particle size of about 14.0 μm, a middle layer thickness of about 1.0 μm, and a surface cladding layer thickness of about 0.1 μm. 0.99 co 0.99 Mg 0.01 o 1.98 f 0.02 / Li 1.05 Ni 0.5 mn 1.45 Al 0.05 o 4 / LATP cathode material. Among them, Li 0.99 co 0.99 Mg 0.01 o 1.98 f 0.02 / Li 1.05 Ni 0.5 mn 1.45 Al 0.05 o 4 / LATP means Li 0.99 co 0.99 Mg 0.01 o 1.98 f 0.02 as the core, Li 1.05 Ni 0.5 mn 1.45 Al 0.05 o 4 It is the middle layer, and the surface layer is coated with nano-LATP material. The SEM image is shown in Figure 4 , TEM image see Figure 5 , see XRD Figure 6 . The SEM image shows that the surface of the material obtained by direct sintering is not very smooth and round due to the presence of lithium nickel manganese oxide. The TEM image shows that the coating thickness on the surface of the material is uniform, and the different observation positions are rel...

Embodiment 2

[0070] With the MgF in step 1 in embodiment 1 2 Change to Al 2 o 3 ,M Co :M Mg = M Co :M Al , Al(NO in step 2 3 ) 3 to Mg(NO 3 ) 2 , other steps are the same to obtain the positive electrode material of this embodiment, see XRD Figure 6 .

Embodiment 3

[0072] With the MgF in step 1 in embodiment 1 2 Change to AlF 3 ,M Co :M Mg = M Co :M Al , Al(NO in step 2 3 ) 3 Change to V(NO 3 ) 2 , the LATP in step 4 was changed to LLZO, and the other steps were the same to obtain the positive electrode material of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com