Preparation method of cesium tungsten bronze/tungsten oxide composite material

A composite material, cesium tungsten bronze technology, applied in tungsten compounds, chemical instruments and methods, tungsten oxide/tungsten hydroxide, etc., can solve the problems of uneven distribution of components, low cost, low material purity, etc., and achieve good application The effect of high value, good repeatability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Disperse 0.5g of tungstic acid in 20mL of pure water at room temperature and stir to form a uniform dispersion; dissolve 0.3g of cesium salt in 10mL of pure water and add it to the dispersion obtained above, stir evenly to form a suspension solution; take 5mL of ethylene glycol, add it to the suspension obtained above, and stir evenly; add it to the reaction kettle, and react at 220°C for 0.5h; centrifuge the obtained product, wash it with water, and Dry at -50°C for 24-48 hours to obtain a composite material of blue powder. In the composite material, the mass ratio of cesium tungsten bronze to tungsten oxide is 1:0.77.

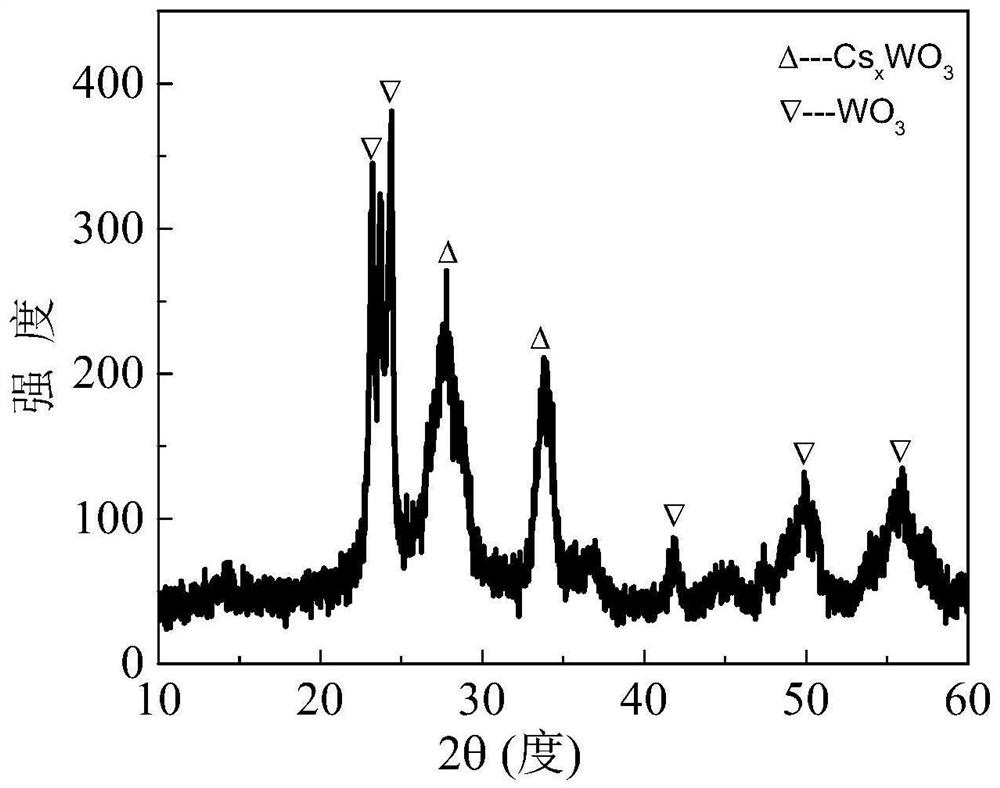

[0052] An appropriate amount of sample was taken for XRD detection. Comparing the obtained spectrum with the standard spectrum, it is found that it is composed of the spectrum of two compounds of cesium tungsten bronze (JCPDS81-1244) and tungsten oxide (JCPDS 83-0951), indicating that the prepared material is cesium tungsten bronze / oxide Tungsten com...

Embodiment 2

[0054] Disperse 0.5g of tungstic acid in 20mL of pure water at room temperature and stir to form a uniform dispersion; dissolve 0.61g of cesium salt in 10mL of pure water and add it to the dispersion obtained above, stir evenly to form a suspension solution; then take 5mL ethylene glycol, add it to the suspension obtained above, and stir evenly; add it to the reaction kettle, and react at 230°C for 3h; centrifuge the obtained product, wash it with water, and put it in 30- Dry at 50°C for 24-48h to obtain a blue powder. In the composite material, the mass ratio of cesium tungsten bronze to tungsten oxide is 1:0.38.

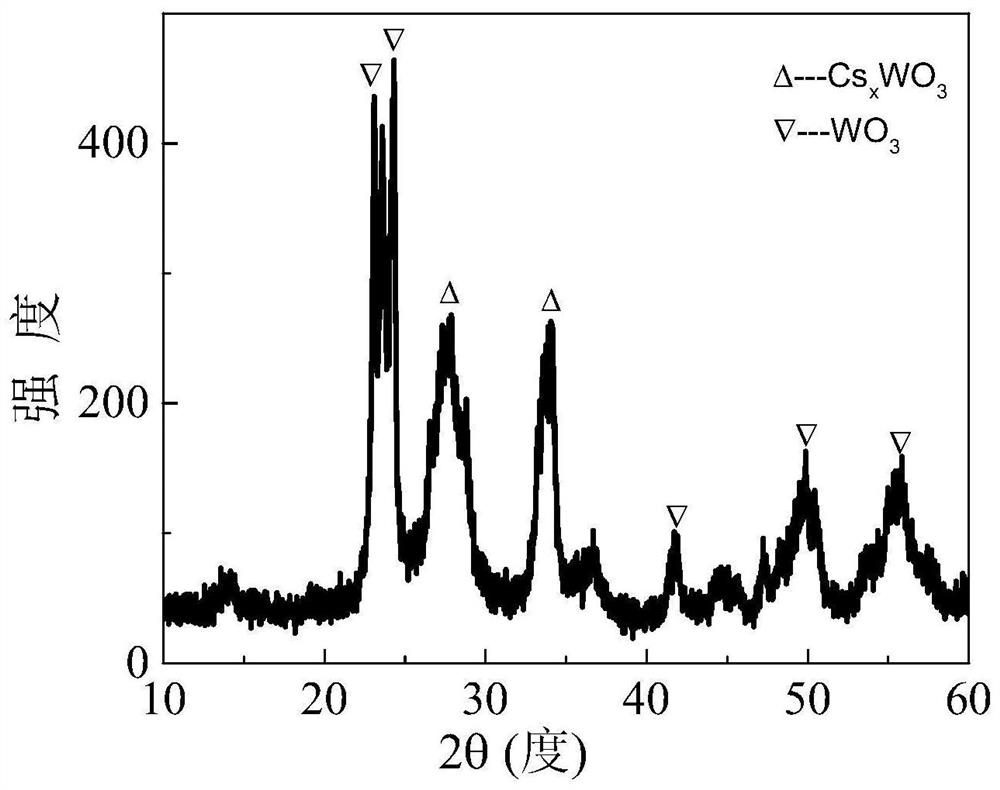

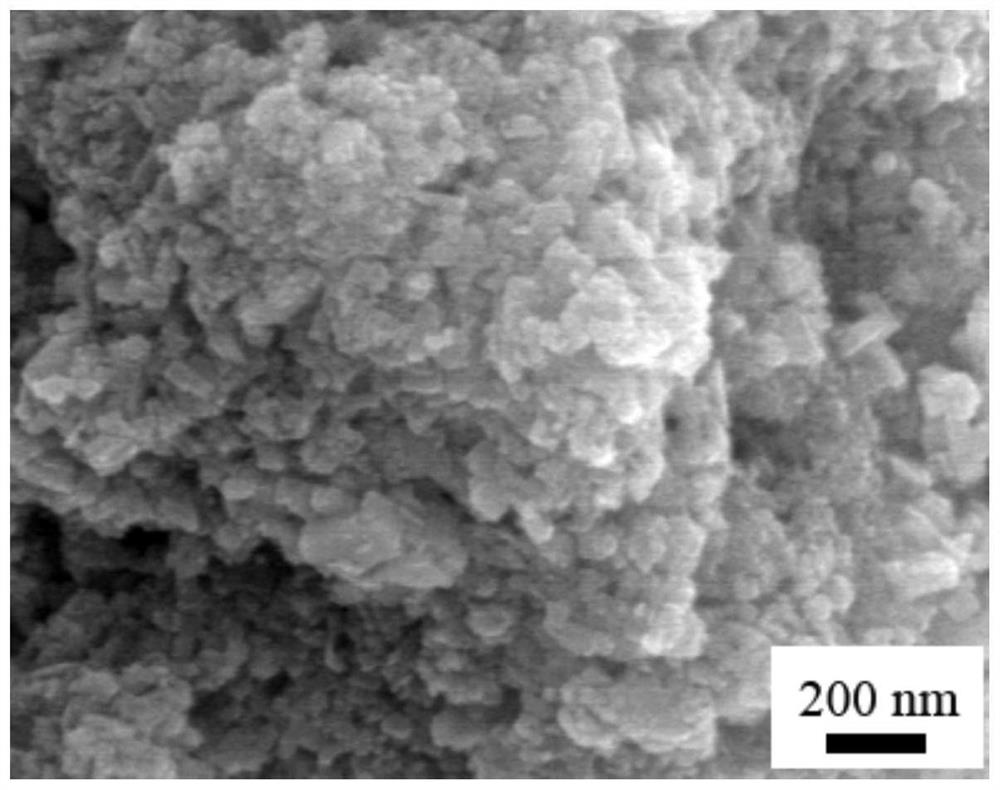

[0055] An appropriate amount of sample was taken for XRD detection. Comparing the obtained spectrum with the standard spectrum, it is found that it is composed of the spectrum of two compounds of cesium tungsten bronze (JCPDS81-1244) and tungsten oxide (JCPDS 83-0951), indicating that the prepared material is cesium tungsten bronze / oxide Tungsten composites. Ano...

Embodiment 3

[0057] Disperse 0.5g of tungstic acid in 20mL of pure water at room temperature and stir to form a uniform dispersion; dissolve 0.93g of cesium salt in 10mL of pure water and add it to the dispersion obtained above, stir evenly to form a suspension solution; then take 5mL ethylene glycol, add it to the suspension obtained above, and stir evenly; add it to the reaction kettle, and react at 230°C for 16h; centrifuge the obtained product, wash it with water, and in 30- Dry at 50°C for 24-48h to obtain a blue powder. In the composite material, the mass ratio of cesium tungsten bronze to tungsten oxide is 1:0.25.

[0058] An appropriate amount of sample was taken for XRD detection. Comparing the obtained spectrum with the standard spectrum, it is found that it is composed of the spectrum of two compounds of cesium tungsten bronze (JCPDS81-1244) and tungsten oxide (JCPDS 83-0951), indicating that the prepared material is cesium tungsten bronze / oxide Tungsten composites. Another s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com