Electrochromic coating and preparation method thereof as well as electrochromic film and preparation method thereof

An electrochromic film, electrochromic technology, applied in multi-color effect coatings, coatings, optics, etc., can solve the problems of poor resin aging resistance, low operating temperature and low service life of electrochromic films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

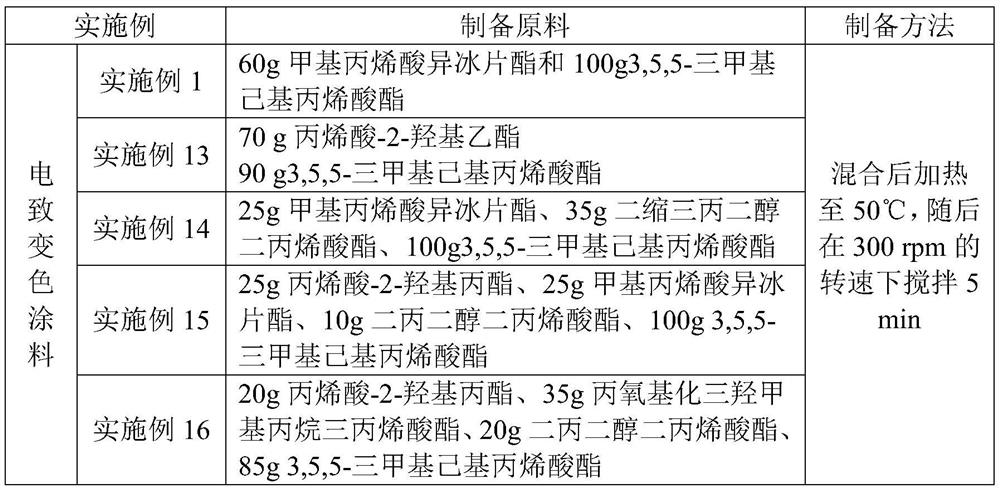

[0064] The preparation steps of electrochromic paint are:

[0065] S1. First mix isobornyl methacrylate and 3,5,5-trimethylhexyl acrylate and heat to 50°C, then stir at 300rpm for 5min, so that isobornyl methacrylate and 3,5 , 5-trimethylhexyl acrylate is polymerized to obtain a liquid prepolymer in a transparent viscous state;

[0066] S2. Add benzoin bisformaldehyde to the prepolymer, and stir for 10 minutes at a speed of 200 rpm, so that the benzoin bisformaldehyde is fully dissolved;

[0067] S3. After adding β-carboxyethyl acrylate and UV curable resin 07B to the liquid obtained in S2, stir at 200 rpm for 10 minutes to form a resin;

[0068] S4. Add mixed liquid crystals to the resin, and then stir for 30 minutes at a speed of 200 rpm;

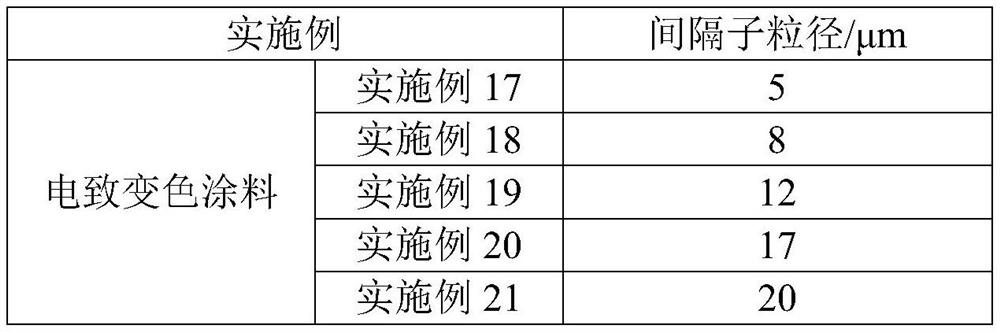

[0069] S5, then adding a 15 μm spacer, and stirring at a speed of 200 rpm for 20 min to obtain a coating mixture;

[0070] S6. Use ultrasonic waves to disperse the coating mixture of S5 for 30 minutes, so as to further fully mix all th...

Embodiment 22-28

[0110] The difference between Examples 22-28 of the electrochromic film and Example 1 of the electrochromic film is that the process parameters for preparing the electrochromic film in this electrochromic film comparative example are different, and the others are the same as in Example 1 of the electrochromic film. See Table 6.

[0111] Preparation process in Table 6 electrochromic film embodiment 22-28

[0112]

[0113] Comparative example of electrochromic film

[0114] Electrochromic film comparative example 1-12

[0115] The difference between the electrochromic film comparative examples 1-12 and the electrochromic film embodiment 1 is that the electrochromic coating selected in the electrochromic film comparative example is different, and the others are the same as the electrochromic film embodiment 1, see Table 7 for details .

[0116] Table 7 Preparation of Electrochromic Film Comparative Examples 1-12 Selection of Electrochromic Coatings

[0117]

[0118] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com