Ultralow-density proppant and preparation method thereof

A technology of ultra-low density and proppant, which is applied in chemical instruments and methods, earthwork drilling, mining fluid, etc. It can solve the problems of low density of narrow branch joints and poor proppant laying effect, etc., and achieve easy heat transfer And control, improve filling efficiency, improve the effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

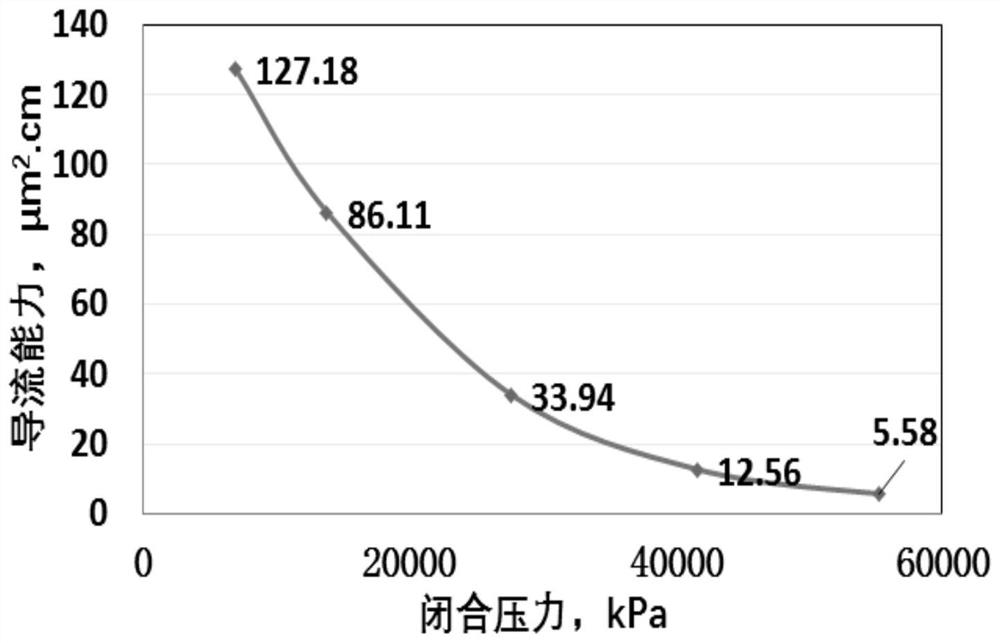

Embodiment 1

[0052]S11, 130 kg of water is placed in a 500l synthetic kettle, warmed and constant to 80 ° C, under stirring conditions, sequentially add 15 kg of magnesium magnesium sulfate solution and 15 kg of sodium carbonate solution, and mix it, wherein the concentration of magnesium sulfate solution In 11%, the concentration of the sodium carbonate solution was 10%;

[0053]S12, 0.016 kg of styrene-maleic anhydride copolymer is sequentially added to the solution obtained in step S11 and 0.028 kg2,6-di-tert-butyl-4-methylphenol, mixed with mixed liquid phase after mixing;

[0054]S13, add density to the liquid phase to 0.4 kg / m30.96kg of hollow glass microbeads having a diameter of 0.31 mm;

[0055]S14, under stirring conditions, 32.00 kg of monomers (30.72 kg of styrene, 1.28 kg of divinylbenzene) were continued to step S13, while filled with nitrogen in the solution, after the air in the oil, close The synthetic kettle valve continues to be charged into the synthetic kettle to cause 0.6 MPa in t...

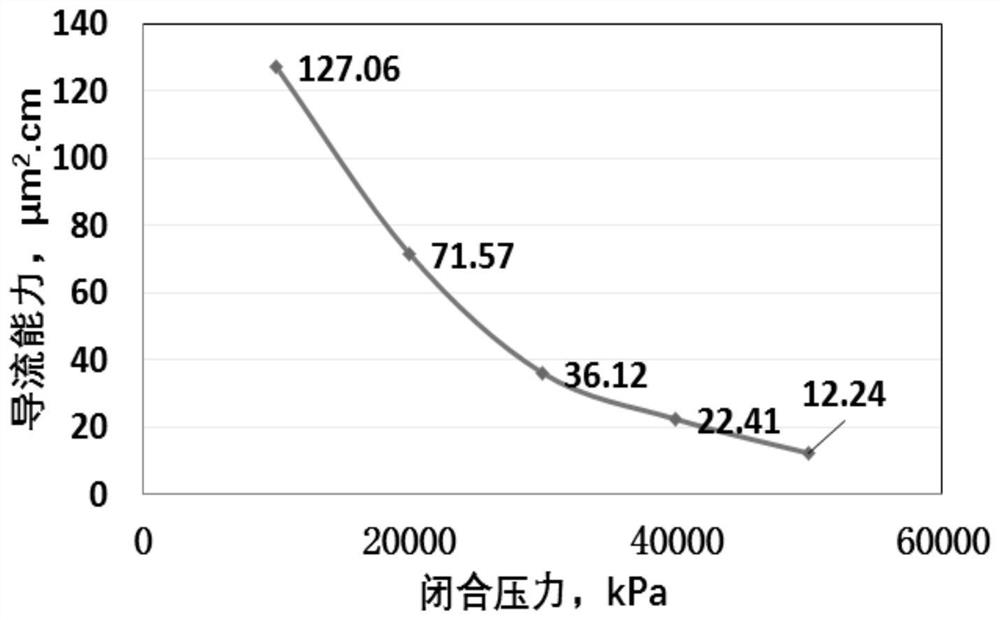

Embodiment 2

[0059]In Example 2 S21, S22, S25 were the same as in Example 1;

[0060]Among them, S23 is added to the liquid phase to 0.45 kg / m.3Hollow glass microbead 1.18kg in diameter is 0.31mm;

[0061]S24, under stirring conditions, 32.00 kg of styrene (29.44 kg of styrene, 2.56 kg of divinylbenzene) was continued to step S23, while filled with nitrogen in the solution, after the air in the oil, close The synthetic kettle valve continues to be charged into the synthetic kettle to cause 0.6 MPa in the synthetic kettle to obtain reaction liquid;

[0062]S26, sequentially separate, washing, dehydration, drying, and sieving the polymer product mixture, resulting in a medium intensity proppant 20 / 30 / m.

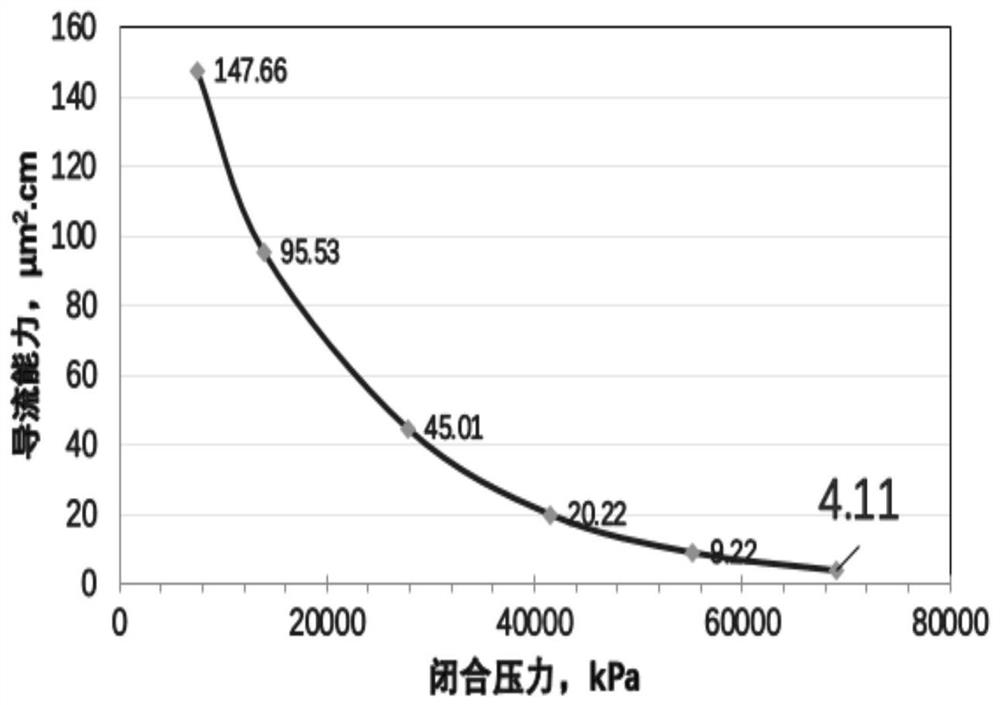

Embodiment 3

[0064]In Example 3 S31, S32, S35 were the same as in Example 1;

[0065]Where S33, the density is 0.5 kg / m into the liquid phase.3Hollow glass microbead 1.13kg in diameter is 0.3mm;

[0066]S34, under stirring conditions, 32.00 kg of monomer (26.88 kg of styrene, 5.12 kg of dizene) obtained in step S33, while filled with nitrogen in the solution, after the air in the kettle, close The synthetic kettle valve continues to be charged into the synthetic kettle to cause 0.6 MPa in the synthetic kettle to obtain reaction liquid;

[0067]S36, sequentially separate, washing, dehydration, drying, and sieved, resulting in high strength proppants 20 / 30 / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com