Amphoteric cellulose silk efficient adsorption material and preparation method and application thereof

A technology of amphoteric cellulose and adsorption materials, which is applied in the field of amphoteric cellulose silk high-efficiency adsorption materials and its preparation, and can solve the problems of inability to provide reaction sites, unsafe drinking standards, and limited introduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

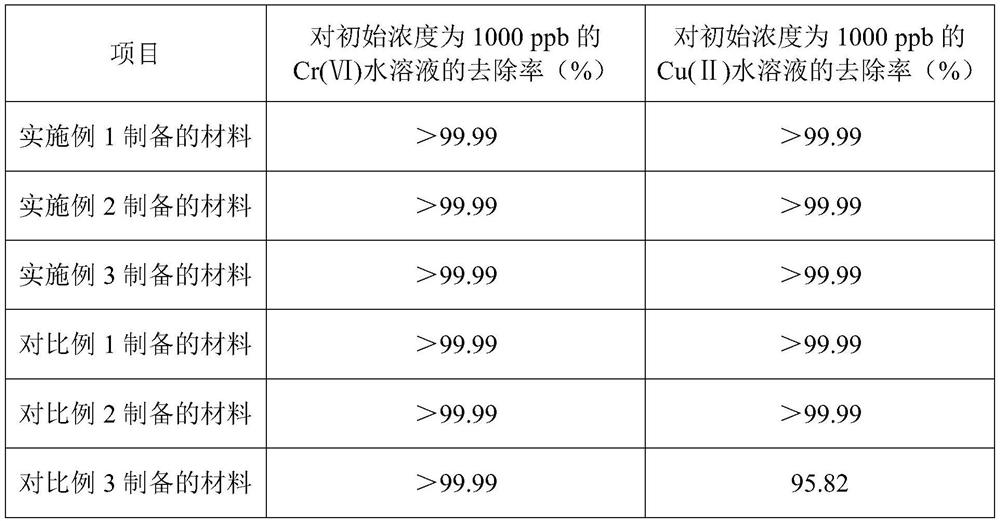

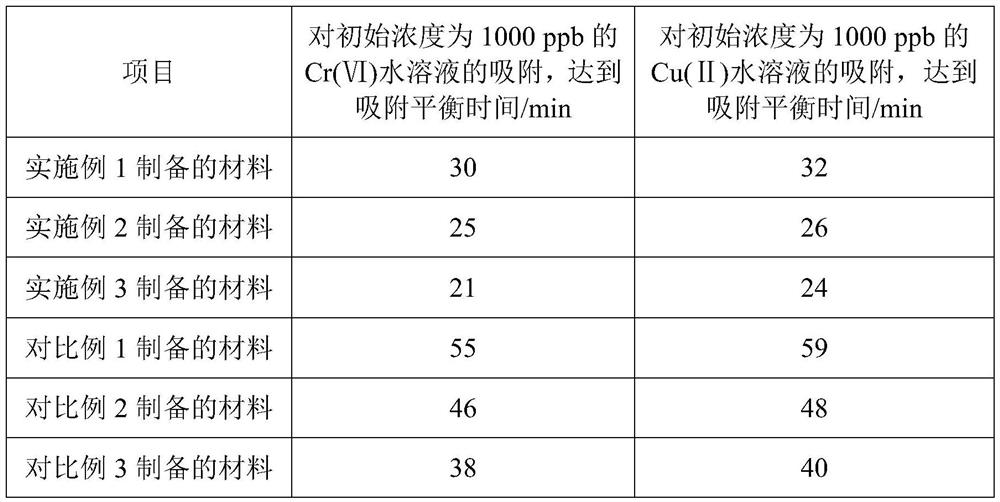

Examples

Embodiment 1

[0029] Example 1: Preparation of amphoteric cellulose filament high-efficiency adsorption material

[0030](1) Add carboxylated nanocellulose to a polyethyleneimine solution with a molecular weight of 75000 mass fraction of 10%, the mass ratio of carboxylated nanocellulose and polyethyleneimine is 1:5, and stir until carboxylated nanofibers The cellulose is completely and uniformly dispersed, and a blend of carboxylated nanocellulose and polyethyleneimine is obtained. Graphene oxide was dispersed in water and subjected to ultrasonic activation treatment. The ultrasonic power was 100W, the ultrasonic time was 60min, and the concentration of the graphene oxide dispersion was 2.5mg / L. The blend of carboxylated nanocellulose and polyethyleneimine and the graphene oxide dispersion liquid after ultrasonic activation treatment were dropped on the polystyrene plate respectively, and when the interface of the two droplets was in contact, the blend It is drawn into filamentous fibers w...

Embodiment 2

[0032] Example 2: Preparation of amphoteric cellulose filament high-efficiency adsorption material

[0033] (1) Add carboxylated nanocellulose to the polyethyleneimine solution with a molecular weight of 75000 mass fraction of 2%, the mass ratio of carboxylated nanocellulose and polyethyleneimine is 1:7.5, and stir until carboxylated nanofibers The cellulose is completely and uniformly dispersed, and a blend of carboxylated nanocellulose and polyethyleneimine is obtained. Graphene oxide was dispersed in water and subjected to ultrasonic activation treatment. The ultrasonic power was 500 W, the ultrasonic time was 90 min, and the concentration of the graphene oxide dispersion was 7.5 mg / L. The blend of carboxylated nanocellulose and polyethyleneimine and the dispersion of graphene oxide were dropped on the polystyrene plate, and when the interface of the two droplets was in contact, the blend and graphene oxide were pulled into a Filamentous fibers, the two are combined into f...

Embodiment 3

[0035] Example 3: Preparation of amphoteric cellulose filament high-efficiency adsorption material

[0036] (1) Add carboxylated nanocellulose to a polyethyleneimine solution with a molecular weight of 75000 mass fraction of 20%, the mass ratio of carboxylated nanocellulose and polyethyleneimine is 1:10, and stir until carboxylated nanofibers The cellulose is completely and uniformly dispersed, and a blend of carboxylated nanocellulose and polyethyleneimine is obtained. Graphene oxide was dispersed in water and subjected to ultrasonic activation treatment. The ultrasonic power was 1000 W, the ultrasonic time was 120 min, and the concentration of the graphene oxide dispersion was 10 mg / L. The blend of carboxylated nanocellulose and polyethyleneimine and the graphene oxide dispersion were dropped on the polystyrene plate, and when the interface of the two droplets was in contact, the blend was combined with graphene oxide to form a Filamentous fibers, the two are combined into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com