Combined machining method suitable for threaded hole of hard alloy cutter bar

A cemented carbide knife and composite machining technology, which is used in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problem of difficulty in ensuring the size and accuracy of the internal thread of cemented carbide tool bars, low processing efficiency, non-uniform shrinkage, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

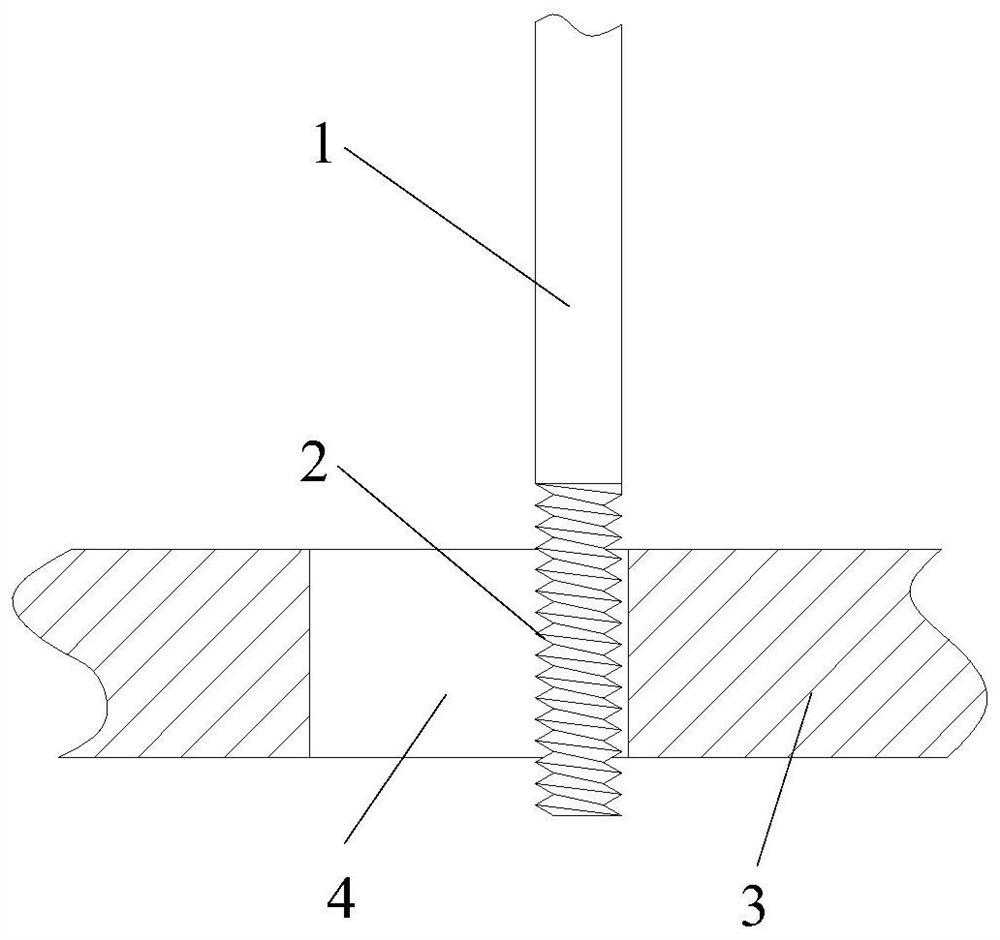

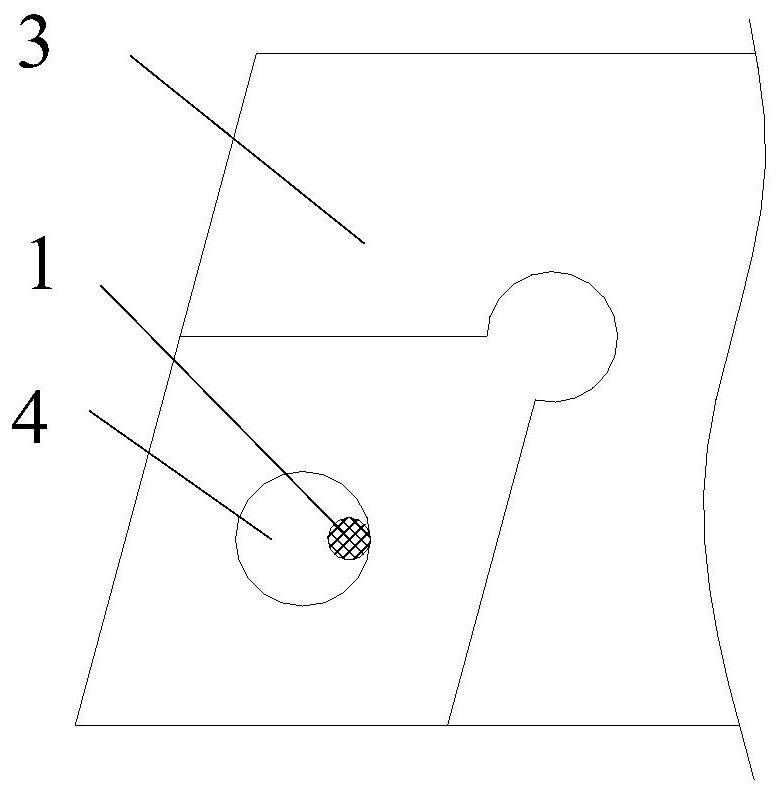

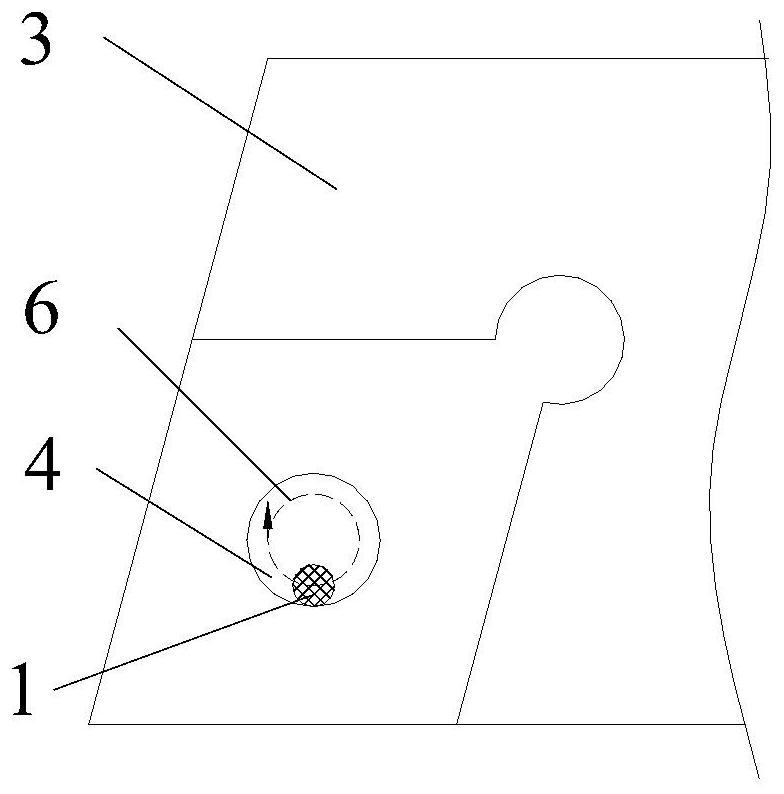

[0028] see Figure 1 to Figure 4 , this embodiment discloses a composite processing method suitable for threaded holes of cemented carbide tool rods, the composite processing method is carried out in sequence according to the following steps:

[0029] Step 1. Process the threaded bottom hole 4 on the cemented carbide shank 3 by means of laser or electric discharge machining. The threaded bottom hole 4 is a circular smooth hole that penetrates up and down; because both laser cutting and electric spark can realize superhard High-efficiency machining of materials, a circular smooth hole is machined on the cemented ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com