Polyimide composite glue, black matte polyimide material and its preparation and application

A technology of polyimide and composite glue, applied in the direction of sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problems of limiting the diversity of processing methods, poor solubility, etc., and achieve good storage stability , Improve processing performance, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

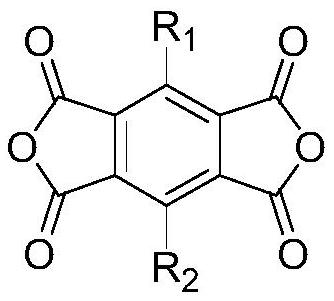

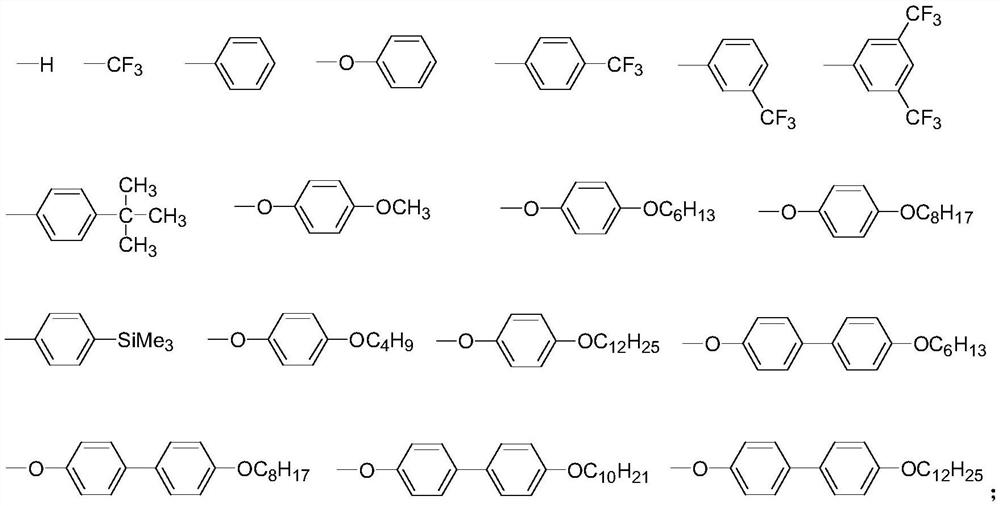

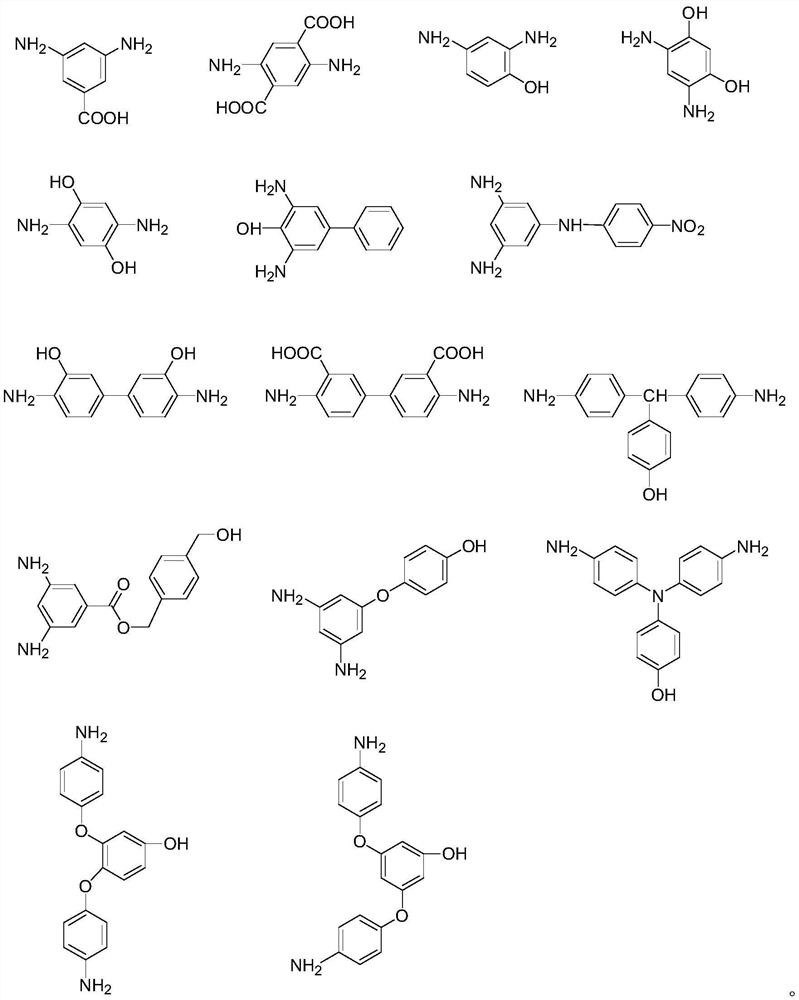

Method used

Image

Examples

Embodiment 1

[0047] Add 10.81g of dihydroxybenzidine, 13.60g of 3,3'-dicarboxybenzidine and 335.64g of dry DMF into a 1000ml three-necked flask, and stir in an ice-water bath for 0.5h. After the diamine is completely dissolved, slowly add 20.12g of 3, 6-diphenoxy-pyridine and 14.71g of 3-phenyl-phthalic anhydride, after the reaction is complete, add 20g of a chemical imidization reagent with a mass ratio of acetic anhydride / pyridine of 3:1, heat up to 165°C for reflux reaction After 3-4 hours, purify to obtain soluble polyimide glue.

[0048] Blackness value 276, tinting strength 110%, carbon black with a particle size of 17nm and dry DMF were sand-milled to obtain a carbon black slurry with a mass fraction of 10%, SiO 2 Treat it with dry DMF through a high-speed disperser to obtain a matting powder dispersion with a mass fraction of 10%. Add 5.0 g of carbon black slurry and 5.0 g of matting powder dispersion into 100.0 g of soluble polyimide glue, and disperse by mechanical stirring to p...

Embodiment 2

[0050] Add 10.81g of dihydroxybenzidine, 7.00g of 4,6-dihydroxym-phenylenediamine and 298.24g of dry DMF into a 1000ml three-neck flask, stir in an ice-water bath for 0.5h, and slowly add 20.12g of 3 , 6-Diphenoxypyrophthalic anhydride and 14.71g of 3-phenylpyrophthalic anhydride, after the reaction is complete, add 20g of a chemical imidization reagent with a mass ratio of acetic anhydride / pyridine of 3:1, heat up to 165°C and reflux React for 3-4 hours, and purify to obtain soluble polyimide glue.

[0051] Blackness value 276, tinting strength 110%, carbon black with a particle size of 17nm and dry DMF were sand-milled to obtain a carbon black slurry with a mass fraction of 10%, SiO 2 Treat it with dry DMF through a high-speed disperser to obtain a matting powder dispersion with a mass fraction of 10%. Add 5.0 g of carbon black slurry and 5.0 g of matting powder dispersion into 100.0 g of soluble polyimide glue, and disperse by mechanical stirring to prepare soluble black m...

Embodiment 3

[0053] Add 10.81g of dihydroxybenzidine, 7.00g of 2,5-dihydroxy-p-phenylenediamine and 298.24g of dry DMF into a 1000ml three-neck flask, stir in an ice-water bath for 0.5h, and slowly add 20.12g of 3 , 6-Diphenoxypyrophthalic anhydride and 14.71g of 3-phenylpyrophthalic anhydride, after the reaction is complete, add 20g of a chemical imidization reagent with a mass ratio of acetic anhydride / pyridine of 3:1, heat up to 165°C and reflux React for 3-4 hours, and purify to obtain soluble polyimide glue.

[0054] Blackness value 276, tinting strength 110%, carbon black with a particle size of 17nm and dry DMF were sand-milled to obtain a carbon black slurry with a mass fraction of 10%, SiO 2 Treat it with dry DMF through a high-speed disperser to obtain a matting powder dispersion with a mass fraction of 10%. Add 5.0 g of carbon black slurry and 5.0 g of matting powder dispersion into 100.0 g of soluble polyimide glue, and disperse by mechanical stirring to prepare soluble black ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com