Esterification method for improving dispersity of hydroxyl-containing nano material

A nanomaterial, dispersive technology, applied in nonlinear optics, instruments, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

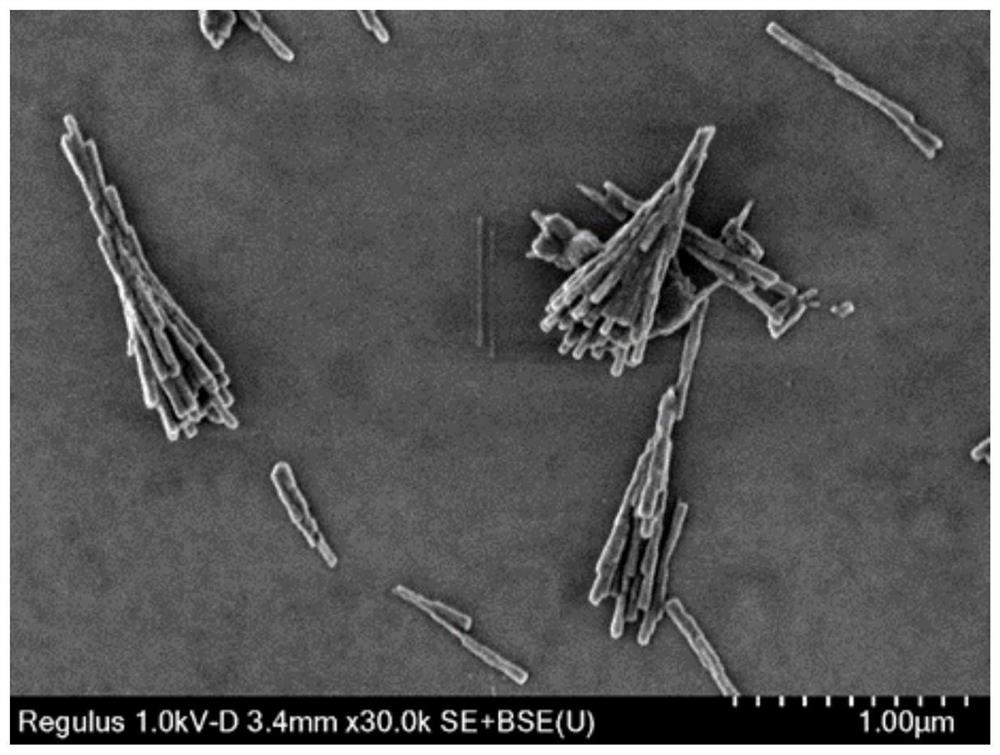

[0040] Dissolve 3g of calcium iodide, 2g of iodine and 4g of nitrocellulose into 40mL of isoamyl acetate, add 1g of DPA-modified hydroxyapatite nanorods in Preparatory Example 2, and then add 3g of 2,5-pyrazinedicarboxylic acid and 4g of methanol, stirred for 30min, mixed thoroughly and placed in an oil bath at 40°C for 1h. Add 0.5mL triethylamine and 1mL stearyl chloride directly, and continue the reaction for 12h. After cooling, the reaction product was centrifuged at 2000r / min, the solid was discarded, and then centrifuged at 10000r / min, the solid was washed 3 times with isoamyl acetate to obtain an iodine-doped calcium complex with octadecyl modification on the surface. The core-shell composite nanomaterial VII (which is the nanomaterial containing hydroxyl groups in this example) is a core-shell composite nanomaterial VII (which is the hydroxyl group-containing nanomaterial in this example), and its appearance is as follows figure 1 shown.

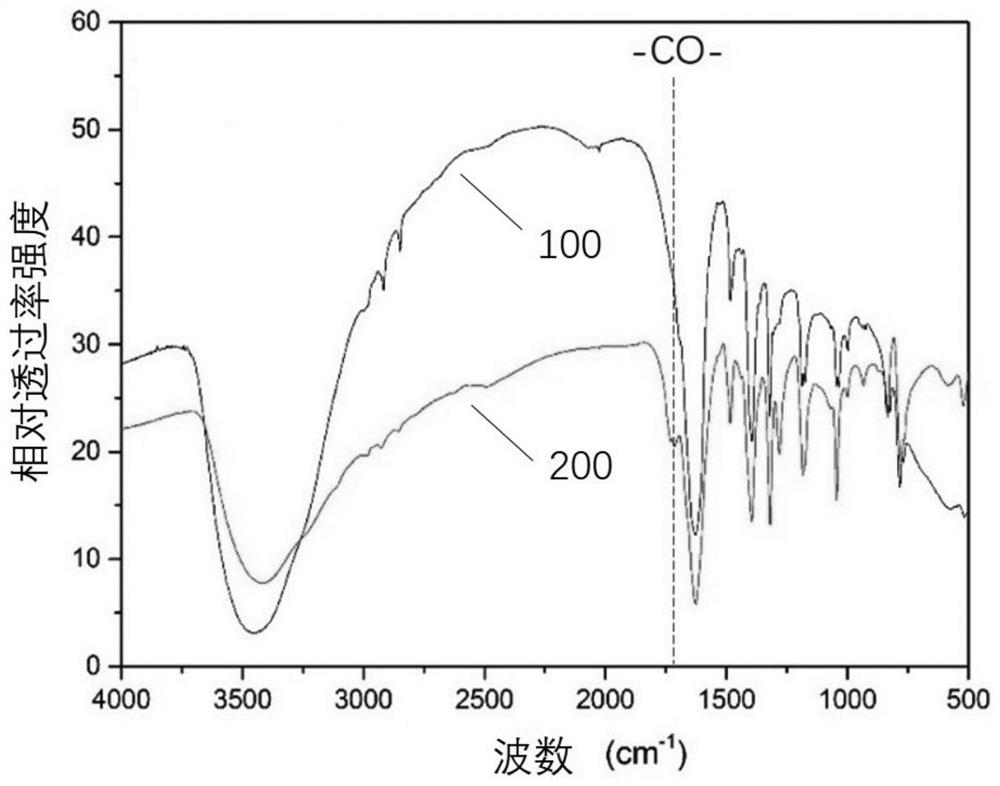

[0041] Analysis of the infra...

Embodiment 2

[0043] Dissolve 3g of calcium iodide, 2g of iodine and 4g of nitrocellulose into 40mL of isoamyl acetate. After fully dissolving, add 3g of 2,5-pyrazinedicarboxylic acid and 4g of methanol in sequence, stir for 30min, and mix well Then put it in a 40°C oil bath and react for 1h. Add 0.5mL triethylamine and 1mL stearyl chloride directly, and continue the reaction for 12h. After cooling, the reaction product was centrifuged at 2000r / min, the solid was discarded, and then centrifuged at 10000r / min, the solid was washed 3 times with isoamyl acetate to obtain an iodine-doped calcium complex with octadecyl modification on the surface. Polymer material VIII (which is the nanomaterial containing hydroxyl groups in this embodiment).

[0044] Comparative Example 3 is an iodine-doped calcium coordination polymer material that is not modified by stearoyl chloride, and Example 2 is an iodine-doped calcium coordination polymer material that is modified by stearoyl chloride; the present app...

Embodiment 3

[0046] Dissolve 0.5g of nickel chloride and 0.8g of terephthalic acid in 40mL of DMF, add 1mL of methanol, mix thoroughly, place in a 100mL three-neck flask, react at a constant temperature of 80°C for 1 hour, and directly add 0.5mL of triethylamine And 1mL stearyl chloride, continue to react for 12h. After cooling, the green solid was centrifuged at 9000r / min, and washed three times with DMF and ultrapure water, respectively, to obtain the metal-organic coordination polymer nanomaterial IX with octadecyl-modified Ni coordination on the surface (It is the nanomaterial containing hydroxyl group in this embodiment).

[0047] Comparative example 1 is the metal-organic coordination polymer material of Ni coordination that is not modified by stearoyl chloride, and embodiment 3 is the metal-organic coordination polymer material of Ni coordination that is modified by stearoyl chloride; In the application, infrared analysis was carried out on the products synthesized in Comparative E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com