A kind of preparation method of se-doped vulcanized polyacrylonitrile material

A technology for vulcanizing polyacrylonitrile and polyacrylonitrile, which is applied to structural parts, lithium batteries, electrical components, etc., can solve the problems of low yield, low sulfur utilization rate, complex synthesis process, etc. Conductivity, effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

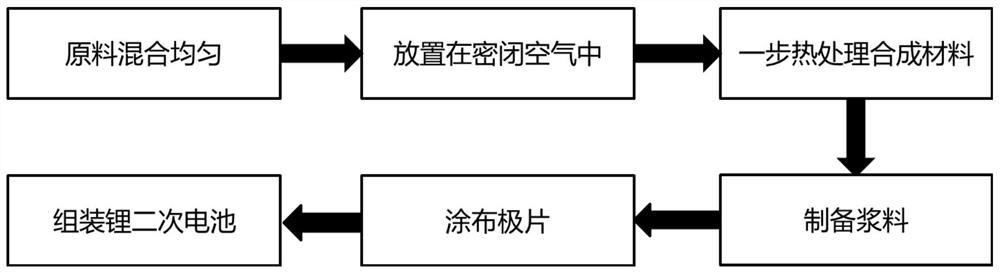

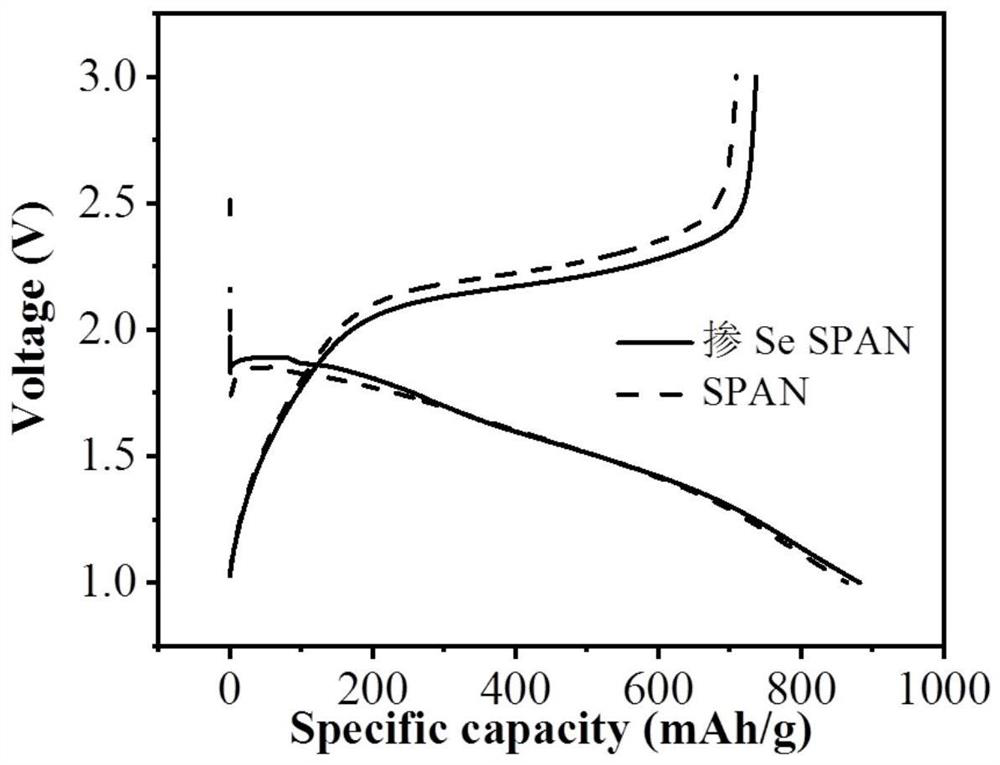

[0041] Example 1 (this example corresponds to SPAN without Se doping)

[0042] Preparation of sulfur active material S1#: Weigh PAN and sublimated sulfur powder in a mass ratio of 1:1.8, add an appropriate amount of ethanol as a dispersant for ball milling and mixing, and the obtained mixture is dried at 80 °C, and dried in an air atmosphere. The powder was placed in a closed reaction kettle and heat-treated at 300°C for 500min, and the obtained black powder was the vulcanized polyacrylonitrile composite material SPAN material.

[0043] Preparation of positive electrode sheet P1#: take 800mg SPAN, 100mg conductive agent (Super P) and 2500mg PAA (4wt% PAA / H 2 O solution), mixed, homogenized, coated with a 300 μm thick doctor blade, vacuum dried at 60 °C, cut into discs with a diameter of Φ10 mm, and then dried at 80 °C under vacuum for 4 hours to obtain a single-sided loading of 6 mg / cm 2 Vulcanized polyacrylonitrile composite material SPAN positive plate.

[0044] Preparat...

Embodiment 2

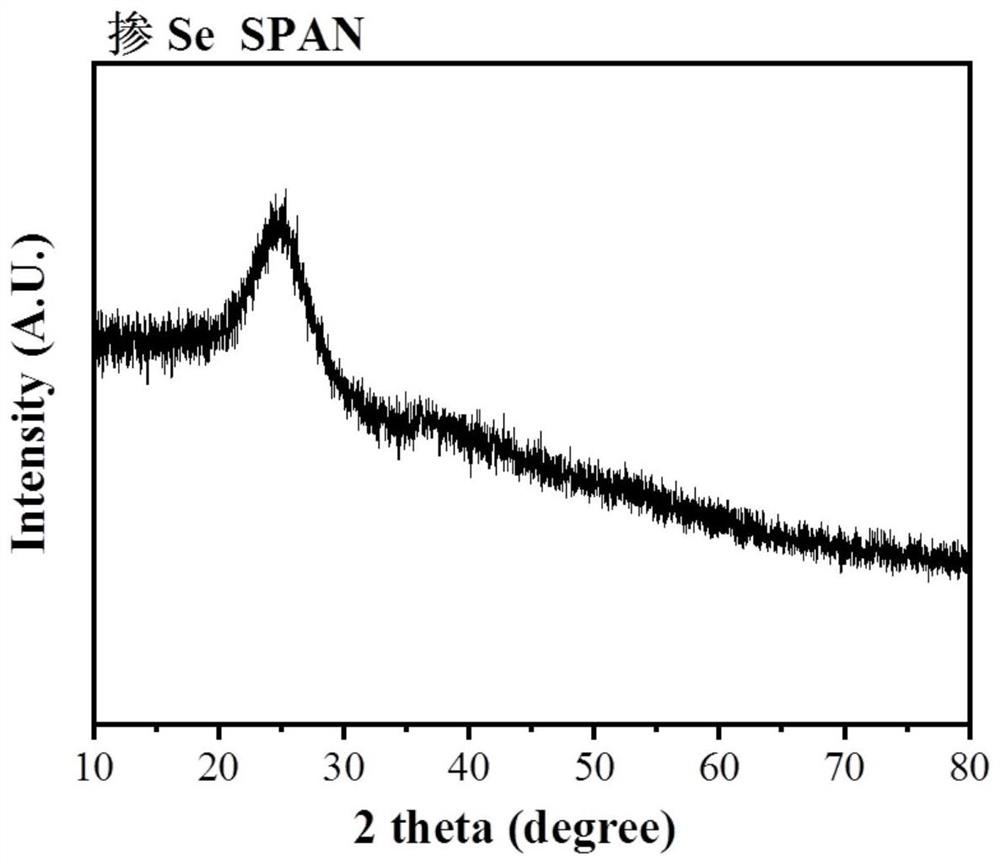

[0045] Example 2 (this example corresponds to Se-doped SPAN)

[0046] Preparation of sulfur active material S2#: take 0.96g Se, 13.44g S, 8g PAN, then add an appropriate amount of ethanol as a dispersant for ball milling and mixing, the obtained mixture is dried at 80 °C, and the dried The powder was placed in a closed reactor and heat-treated at 300 °C for 500 min, and the obtained black powder was the Se-doped vulcanized polyacrylonitrile composite material S. 1-x Se x PAN material.

[0047] Preparation of positive electrode sheet P2#: take 800mg SPAN, 100mg conductive agent (Super P) and 2500mg PAA (4wt% PAA / H 2 O solution), mixed, homogenized, coated with a 300 μm thick doctor blade, vacuum dried at 60 °C, cut into discs with a diameter of Φ10 mm, and then dried at 80 °C under vacuum for 4 hours to obtain a single-sided loading of 6 mg / cm 2 Se-doped vulcanized polyacrylonitrile composite S 1-x Se x PAN cathode sheet.

[0048] Preparation of lithium secondary batte...

Embodiment 3

[0050] Preparation of sulfur active material S3#: the same process as described in Example 2, except that the mass ratio of Se:S was replaced from 1:14 to 1:2.5.

[0051] Preparation of the positive electrode sheet P3#: the same as the preparation method of the positive electrode sheet described in Example 2.

[0052] Preparation of lithium secondary battery C3#: the same process as described in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com