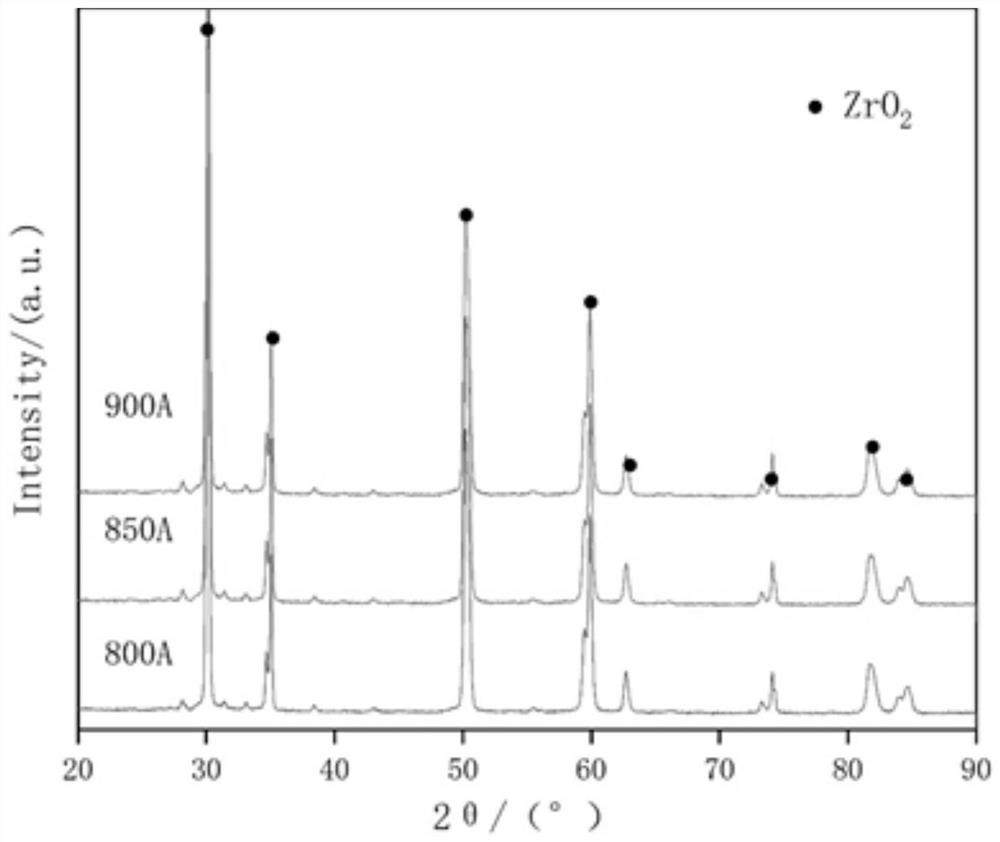

A kind of ysz/graphene composite sealing coating and preparation method thereof

A graphene composite and sealing coating technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of YSZ coating failure, high temperature thermal corrosion of coating, YSZ phase change, etc., to achieve Low cost, improved toughness and wear resistance, enhanced thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

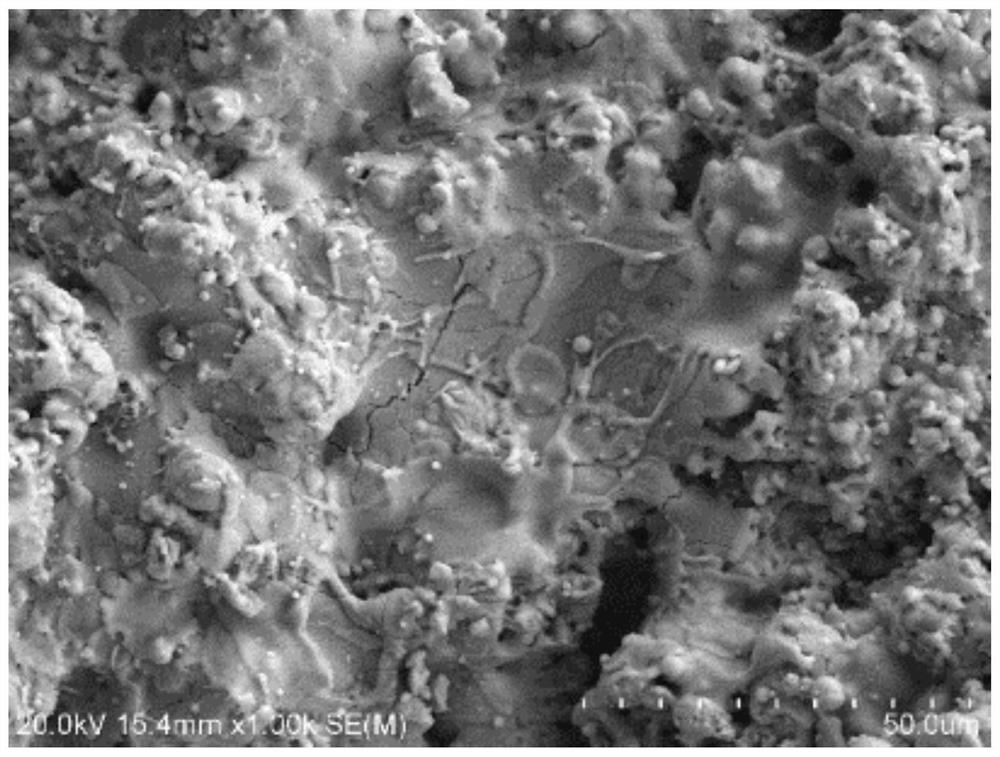

Embodiment 1

[0042] Step 1. Add 964g of nano-YSZ powder, 36g of graphene, 5g of PVA and 1500g of deionized water into the ball mill tank with a ball-to-material ratio of 4:1, and ball mill for 6 hours at a ball mill speed of 150r / min to mix the ingredients evenly. get a suspension;

[0043] Step 2. Transfer the suspension to a spray drying granulation tower for agglomeration and granulation. The granulated powder is first dried in an oven at 80°C for 30 hours, and then passed through a test sieve to obtain a particle size of 20 μm to 90 μm. Nano YSZ / graphene agglomerated powder;

[0044] Among them, the spray drying granulation process parameters are as follows: inlet temperature 240°C, outlet temperature 130°C, nozzle speed 35Hz, peristaltic pump speed 35rpm;

[0045] Step 3. Send the nano-YSZ / graphene agglomerated powder into the induction plasma spheroidization equipment for spheroidization treatment. The powder after spheroidization treatment is first dried in an oven at 100°C for 30 ...

Embodiment 2

[0055] Step 1. Add 976g of nano-YSZ powder, 24g of graphene, 5g of PVA and 1500g of deionized water into the ball mill tank with a ball-to-material ratio of 4:1, and mill for 3 hours at a ball mill speed of 420r / min to mix the ingredients evenly. get a suspension;

[0056] Step 2. Transfer the suspension to a spray drying granulation tower for agglomeration and granulation. The granulated powder is first dried in an oven at 150°C for 20 hours, and then passed through a test sieve to obtain a particle size of 20 μm to 90 μm. Nano YSZ / graphene agglomerated powder;

[0057] Among them, the spray drying granulation process parameters are as follows: inlet temperature 250°C, outlet temperature 140°C, nozzle speed 40Hz, peristaltic pump speed 35rpm;

[0058] Step 3. Send the nano-YSZ / graphene agglomerated powder into the induction plasma spheroidization equipment for spheroidization treatment. The powder after spheroidization treatment is first dried in an oven at 100°C for 30 hour...

Embodiment 3

[0068] Step 1. Add 988g of nano-YSZ powder, 12g of graphene, 5g of PVA and 1500g of deionized water into the ball mill tank with a ball-to-material ratio of 4:1, and mill for 3 hours at a ball milling speed of 420r / min to mix the ingredients evenly. get a suspension;

[0069] Step 2. Transfer the suspension to a spray drying granulation tower for agglomeration and granulation. The granulated powder is first dried in an oven at 150°C for 20 hours, and then passed through a test sieve to obtain a particle size of 20 μm to 90 μm. Nano YSZ / graphene agglomerated powder;

[0070] Among them, the spray drying granulation process parameters are as follows: inlet temperature 260°C, outlet temperature 150°C, nozzle speed 40Hz, peristaltic pump speed 40rpm;

[0071] Step 3. Send the nano-YSZ / graphene agglomerated powder into the induction plasma spheroidization equipment for spheroidization treatment. The powder after spheroidization treatment is first dried in an oven at 100°C for 30 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com