Powder metallurgy aluminum alloy chain wheel or gear and preparation method

A powder metallurgy, aluminum alloy technology, applied in the field of aluminum alloy sprockets or gears and the preparation of aluminum alloy sprockets or gears by powder metallurgy technology, can solve the problems of low hardness, complex aluminum alloy composition, narrow control range, etc. Hardness, simple preparation method, and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

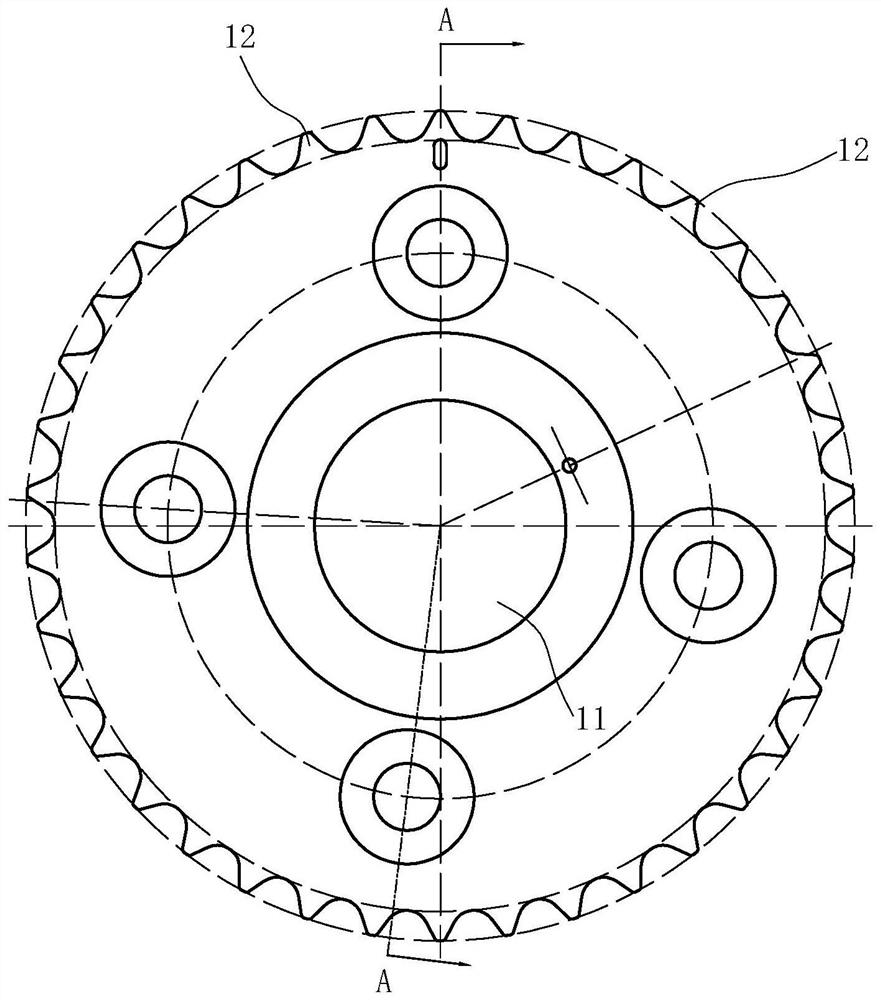

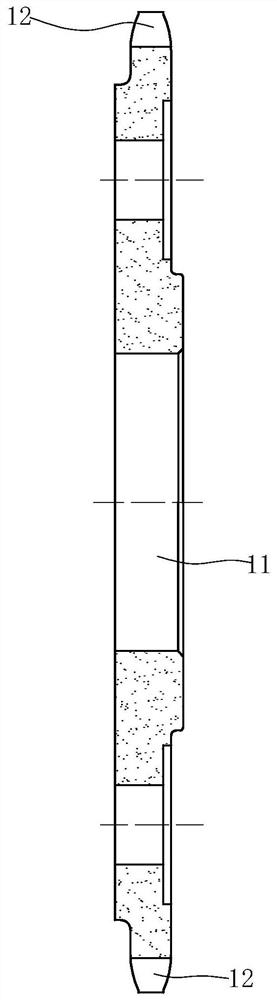

[0035] Such as Figure 1 to Figure 4 Shown is the first preferred embodiment of the present invention.

[0036] The preparation method of the aluminum alloy sprocket of powder metallurgy of the present embodiment comprises the following steps in sequence:

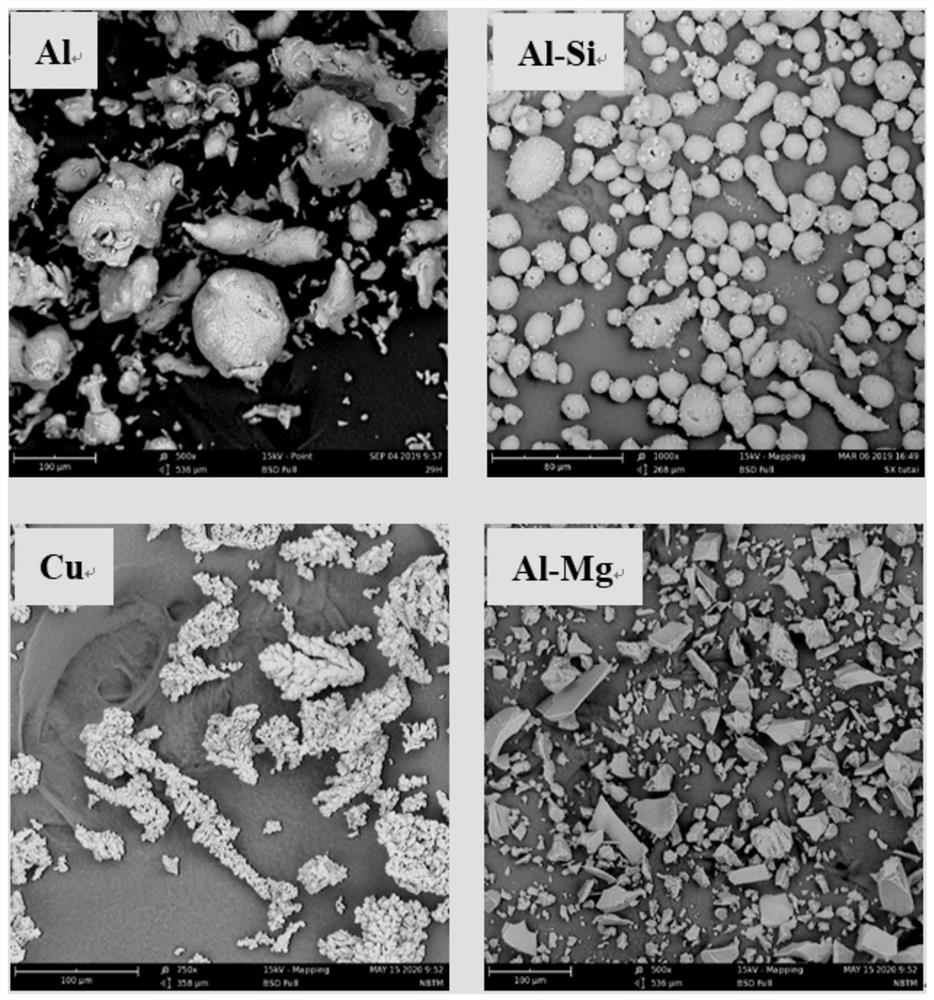

[0037] 1) Mixing: put Al-27Si alloy powder, 2.6wt% electrolytic copper powder, Al-50Mg alloy powder, pure Al powder and 1.5%wt% lubricant in a mixer and stir for 45min, and the ratio is Al-15.5Si- The composition of 2.6Cu-0.65Mg, its composition design is shown in Table 1, and the powder morphology used is shown in figure 2 shown;

[0038] 2) Forming: Press the powder mixed in step 1) on a forming press to form an aluminum alloy sprocket green body, the forming pressure is 200MPa, and the forming density is 2.4g / cm3;

[0039] 3) Sintering: put the sprocket green body in step 2) into a mesh belt furnace and sinter to obtain an aluminum alloy sintered part. The sintering process includes degreasing and sintering. ℃~570℃,...

Embodiment 2

[0045] The difference between this embodiment and the above-mentioned embodiment 1 is that the forming pressure and density of step 2) are different, specifically, the forming pressure is 300Pa, and the forming density is 2.5g / cm 3 The process parameters of step 3) are different, specifically, the degreasing temperature is 450 ℃, the holding time of degreasing is 15min, the sintering temperature is 570 ℃, the holding time of sintering is 120min, the density of the product after sintering is 2.6g / cm3, sintering The HRB hardness of the as-formed product reaches 50, the solid solution temperature is 500°C, the solid solution heat preservation treatment time is 5h, the aging temperature is 200°C, the aging heat preservation time is 72h, and the HRB hardness after aging is 80; the product density of the whole form is 2.65g / cm3, HRB hardness is 80.

Embodiment 3

[0047] The difference between this embodiment and the above-mentioned embodiment 1 is that the forming pressure and density of step 2) are different, specifically, the forming pressure is 450Pa, and the forming density is 2.45g / cm 3 The process parameters of step 3) are different, specifically, the degreasing temperature is 420 ℃, the holding time of degreasing is 90min, the sintering temperature is 560 ℃, the holding time of sintering is 10min, the density of the product after sintering is 2.55g / cm3, sintering The HRB hardness of the as-state product reaches 45, the solid solution temperature is 540°C, the solid solution heat preservation treatment time is 0.5h, the aging temperature is 20°C, the aging heat preservation time is 30h, the HRB hardness after aging is 75, and the product density of the whole form is 2.6 g / cm3, HRB hardness is 70.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com