A flexible composite circuit board with virus-killing function and its manufacturing process

A manufacturing process and composite circuit technology, applied in the direction of printed circuit manufacturing, circuit substrate materials, printed circuits, etc., can solve the problems of easy burnout, increased power consumption, and circuit components burnout, etc. Good effect of oxidation reaction and sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

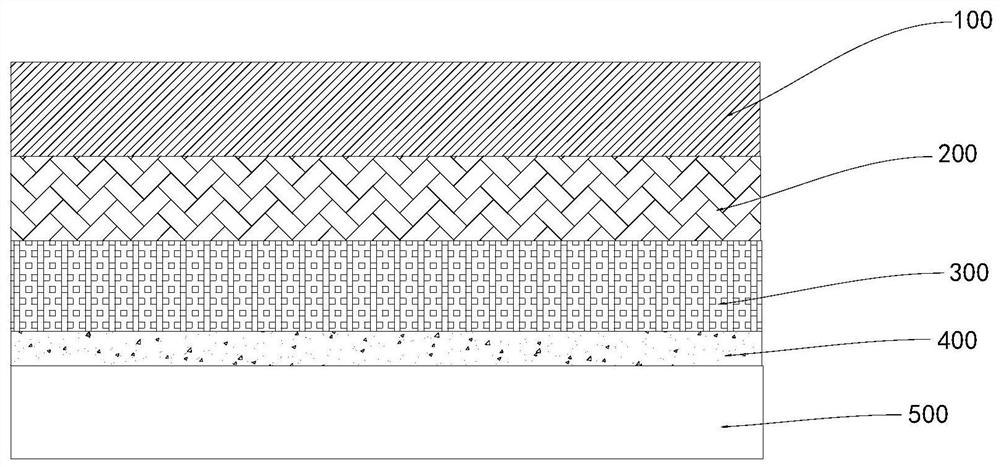

[0028] See figure 1 A flexible composite circuit board having a murderous virus function, from top to bottom, including anti-virus coating 100, an anti-oxidation coating 200, an insulating flexible dielectric film 300, a viscose layer 400, and a copper foil substrate 500.

[0029] Among them, the anti-virus coating 100 includes 90 nano-silver copper alloy mixed particles, 9 parts of the peony extract and 5 parts of zirconia powder.

[0030] Anti-oxidation coating 200 coating includes alumina, and other additives, such as corrosion, toughening, coupling agents, or the like, such as anti-corrosion, toughening agent, coupling agent, or the like; in order to increase other properties, the coating agent can be added to the insulating flexible medium of the organic matter. The film 300 and the main component are better bonded to the alumina, the coupling agent may be a silane coupling agent, a titanate coupling agent or an aluminate coupling agent, and a coupling agent. The addition enh...

Embodiment 2

[0033] See figure 1 A flexible composite circuit board having killiviral function, from top to bottom, including anti-virus coating 100, an anti-oxidation coating 200, an insulating flexible dielectric film 300, a viscose layer 400, and a copper foil substrate 500;

[0034] Among them, the anti-virus coating 100 includes 95 parts of nanochemical alloy mixed particles, 7 parts of peony peel extract and 3 parts of zirconia powder.

[0035] Anti-oxidation coating 200 coating includes alumina, and other additives, such as corrosion, toughening, coupling agents, or the like, such as anti-corrosion, toughening agent, coupling agent, or the like; in order to increase other properties, the coating agent can be added to the insulating flexible medium of the organic matter. The film 300 and the main component are better bonded to the alumina, the coupling agent may be a silane coupling agent, a titanate coupling agent or an aluminate coupling agent, and a coupling agent. The addition enhanc...

Embodiment 3

[0038] See figure 1 A flexible composite circuit board having killiviral function, from top to bottom, including anti-virus coating 100, an anti-oxidation coating 200, an insulating flexible dielectric film 300, a viscose layer 400, and a copper foil substrate 500;

[0039] Among them, the anti-virus coating 100 includes 93 nanochemical alloy mixed particles, 8 parts of peony extracts and 4 parts of zirconia powder.

[0040]Anti-oxidation coating 200 coating includes alumina, and other additives, such as corrosion, toughening, coupling agents, or the like, such as anti-corrosion, toughening agent, coupling agent, or the like; in order to increase other properties, the coating agent can be added to the insulating flexible medium of the organic matter. The film 300 and the main component are better bonded to the alumina, the coupling agent may be a silane coupling agent, a titanate coupling agent or an aluminate coupling agent, and a coupling agent. The addition enhancement of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com